Liquid crystal display screen stress detection equipment based on clamping type limiting

A technology of liquid crystal display and testing equipment, which is applied in the direction of applying stable tension/pressure to test the strength of materials, testing of machine/structural components, measuring devices, etc. , affecting the accuracy of the pressure test of the LCD screen, etc., to achieve the effect of improving stability and accuracy and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

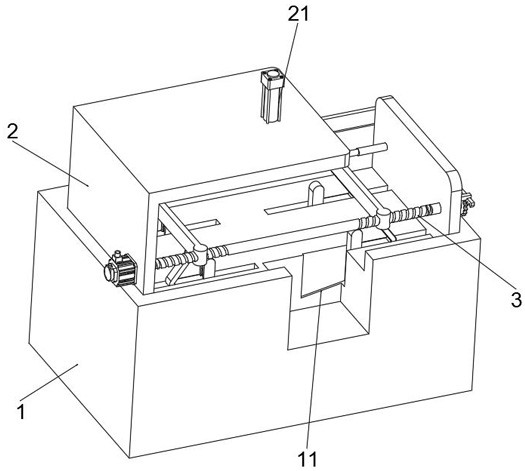

[0044] see Figure 1-Figure 6 As shown, the purpose of this embodiment is to provide a liquid crystal display pressure detection device based on clamping limit, at least including:

[0045] A workbench 1, baffles 2 are symmetrically installed on the surface of the workbench 1, one of the baffles 2 is provided with a horizontal plate on the surface, the surface of the horizontal plate is connected with a cylinder 21, and the cylinder 21 is used to squeeze the liquid crystal display;

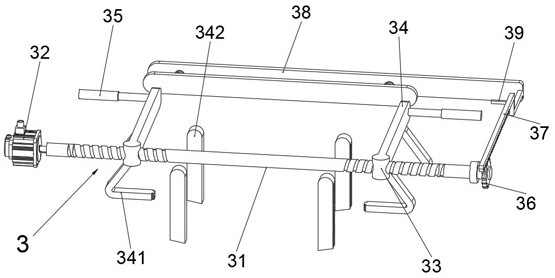

[0046] Limiter 3, limiter 3 is positioned between two baffle plates 2, limiter 3 at least comprises the screw mandrel 31 that is rotatably connected on two baffle plates 2, and the screw groove on the screw mandrel 31 is relatively opened, and the screw One side of the rod 31 runs through the baffle plate 2, and one end of the screw rod 31 is connected with a motor 32, and the motor 32 is fixedly installed with one of the baffle plates 2, and the surface of the screw rod 31 is threadedly connected...

Embodiment 2

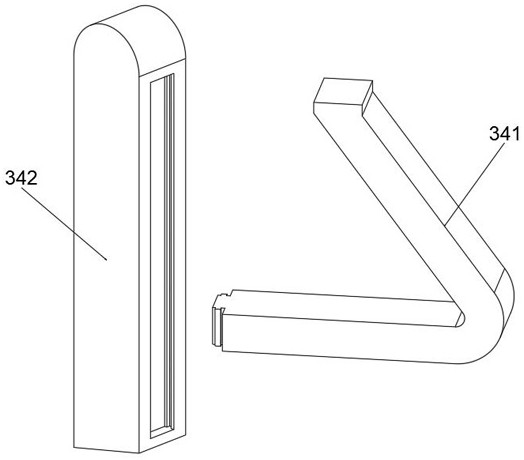

[0054] Considering that during the pressure test of the liquid crystal display, when the personnel misuse, the motor 32 drives the limit plate 34 to continue to clamp, causing accidental breakage of the liquid crystal display, this embodiment makes the following improvements on the basis of embodiment 1 ,Such as Figure 7 and Figure 8 Shown:

[0055] The surface of the workbench 1 is provided with a chip holder 4, the chip holder 4 at least includes a receiving plate 41, the bottom surface of the receiving plate 41 slides with a left side plate 42, the bottom surface of the left side plate 42 slides with a right side plate 43, and the left side plate 42 and the right side plate 43 alternately slide, and the ends of the left side plate 42 and the right side plate 43 are all equipped with an elastic rope body 44, and the other end of the elastic rope body 44 is fixedly connected with the support rod 342, and the surface of the workbench 1 will remain A large amount of liquid ...

Embodiment 3

[0057] Considering that when a large amount of liquid crystal display pressure is carried out at one time, the liquid crystal display that has passed the test cannot be stored alone, and it is easy to mix with other liquid crystal display screens to affect the work efficiency. This embodiment makes the following on the basis of embodiment 2 improvements such as Figure 9 and Figure 11 Shown:

[0058]A cavity 5 is provided on the side of the workbench 1, a chute 14 is provided on the inside of the cavity 5, a slide plate 51 is provided inside the cavity 5, and a connecting block 511 is installed on the bottom of the slide plate 51, and the connecting block 511 is located in the chute 14 Sliding, by vertically placing the liquid crystal display screen that has passed the pressure test between the slide plate 51 and the cavity 5, through the connection between the connecting block 511 and the chute 14, the slide plate 51 slides to limit the position of the liquid crystal displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com