Vacuum low-temperature continuous drying equipment

A drying equipment, vacuum and low temperature technology, applied in the direction of drying solid materials, drying chamber/container, lighting and heating equipment, etc., can solve the problem that the accumulation of solid materials cannot be fully dispersed, the adverse effect of material drying effect, and the low efficiency of water analysis To achieve the effect of sufficient and efficient drying of materials, promotion of rapid volatilization, and promotion of moisture precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

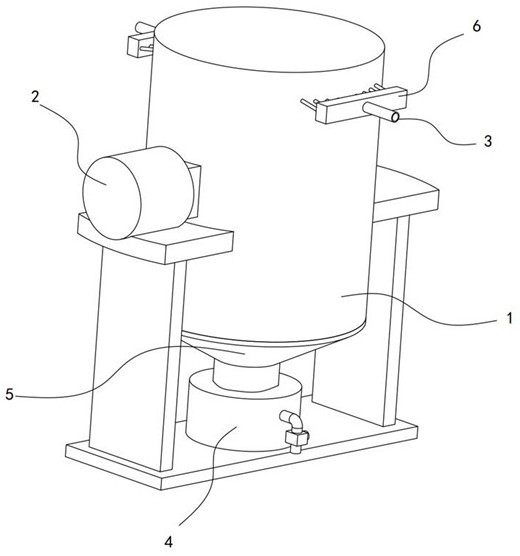

[0031] see Figure 1-9 , a vacuum low-temperature continuous drying equipment, including a straight cylinder 1 and a vacuum pump 2 connected thereto, a cone 5 is installed at the bottom of the straight cylinder 1, a liquid collection box 4 is installed at the bottom of the cone 5, and the inner top of the straight cylinder 1 is installed There are condensing components. The vacuum pump 2 is used to evacuate the inside of the straight cylinder 1 and the cone cylinder 5 to heat the material to promote the vaporization and precipitation of the moisture in the material, and the rising moisture is condensed by the condensing component to realize the drying effect on the material.

[0032] A horizontal frame 10 is fixed inside the straight cylinder 1, a vertical frame 9 is installed on the horizontal frame 10, a fixed ring plate 12 is fixed on the vertical frame 9, a fixed coaming 8 is fixed inside the straight cylinder 1, and the fixed coaming 8 slides A heating plate 28 is instal...

Embodiment 2

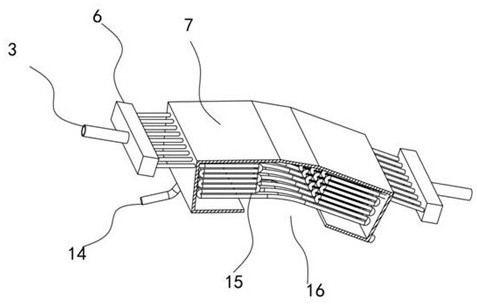

[0041] see Figure 1-9 , on the basis of Embodiment 1, in addition, the traction mechanism includes an outer ring plate 13 fixedly sleeved on the inner ring gear 27, a vertical rod 22 is fixed on the outer ring plate 13, and a lifting rod 22 is slidably installed on the vertical rod 22. Sleeve block 41, guide sleeve 19 is fixed on the inner wall of straight cylinder body 1, slide column 18 connected with evacuation mechanism is slidably installed on guide sleeve 19, fixed plate 20 is fixed on slide column 18, fixed plate 20 and lifting sleeve block 41 A connecting rod 21 is hinged therebetween.

[0042] The incomplete bevel gear 24 is installed in rotation on the vertical frame 9, and the driven bevel gear I25 and the driven bevel gear II26 are connected coaxially on the rotating shaft 11, and the incomplete bevel gear 24 is alternately connected with the driven bevel gear I25 and the driven bevel gear. II26 snap connection.

[0043] Based on the above-mentioned settings, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com