Thermally driven optical fibre switch for micromachinery and its making method

A technology of optical fiber switch and manufacturing method, which is applied in the coupling of optical waveguide and other directions, can solve the problems related to the alignment accuracy of optical fiber in switching performance and the relatively large relationship between the process complexity and the driving mode of micromirror, and achieve low cost, good reliability, The effect of low insertion loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

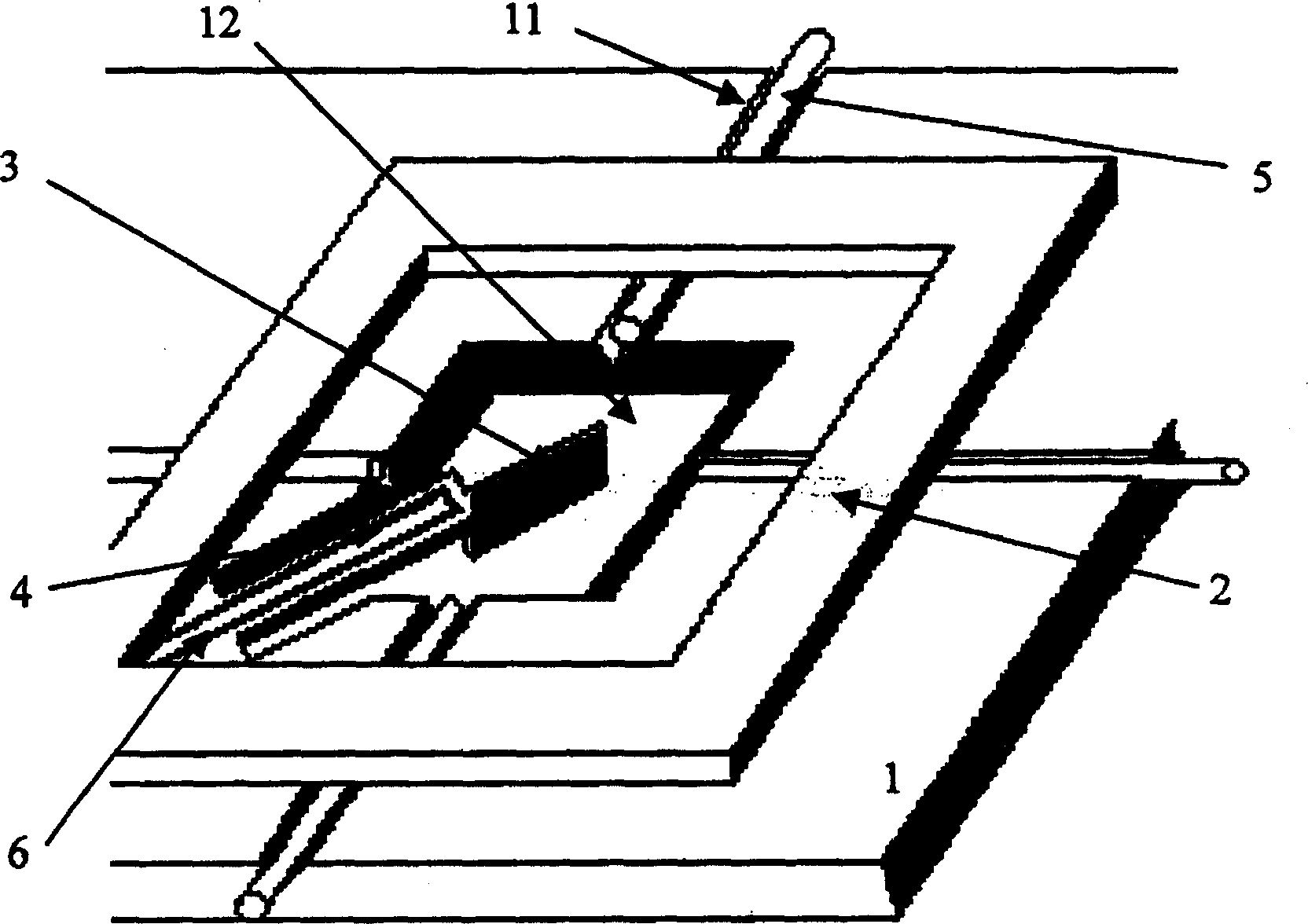

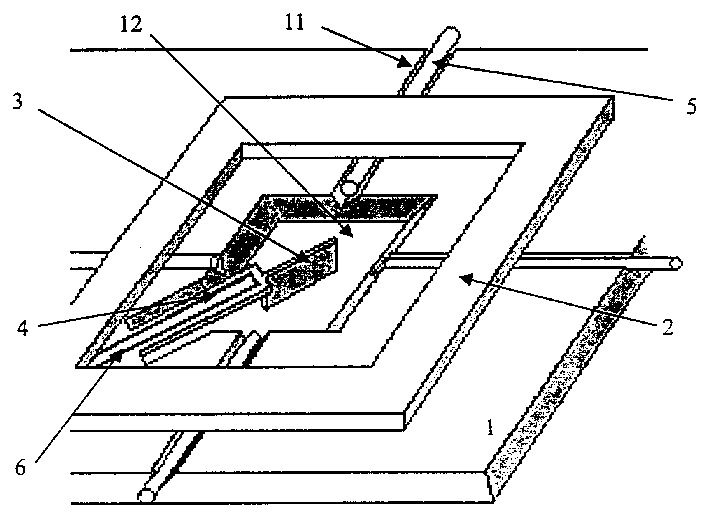

[0011] A heat-driven micromechanical optical fiber switch, the optical fiber switch is composed of a silicon plate 1 for fixing the optical fiber, a silicon plate 2 for pressing the optical fiber, a microreflector 3, a cantilever beam 4, an optical fiber 5, and a heating resistor 6. The surface of the silicon plate 1 is provided with 4 crosses with each other, adjacent vertical optical fiber grooves 11 are provided with optical fibers 5 in the grooves, a pit 12 is arranged in the center of the silicon plate 1 for fixing the optical fibers, and the reflector 3 is located In the pit 12, both sides of the mirror surface form an angle of 45 degrees with the four optical fibers 5, the reflector 3 is fixed on one end of the cantilever beam 4, and the other end of the cantilever beam 4 is connected to the silicon plate 1 on which the optical fiber is fixed, and pressed The silicon plate 2 of the optical fiber is pressed on the silicon plate 1 of the fixed optical fiber in a square fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com