Diaphragms for air springs and air springs

A technology of air springs and diaphragms, applied in the direction of gas shock absorbers, etc., to achieve the effect of expanding effective space, excellent appearance, and superior durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

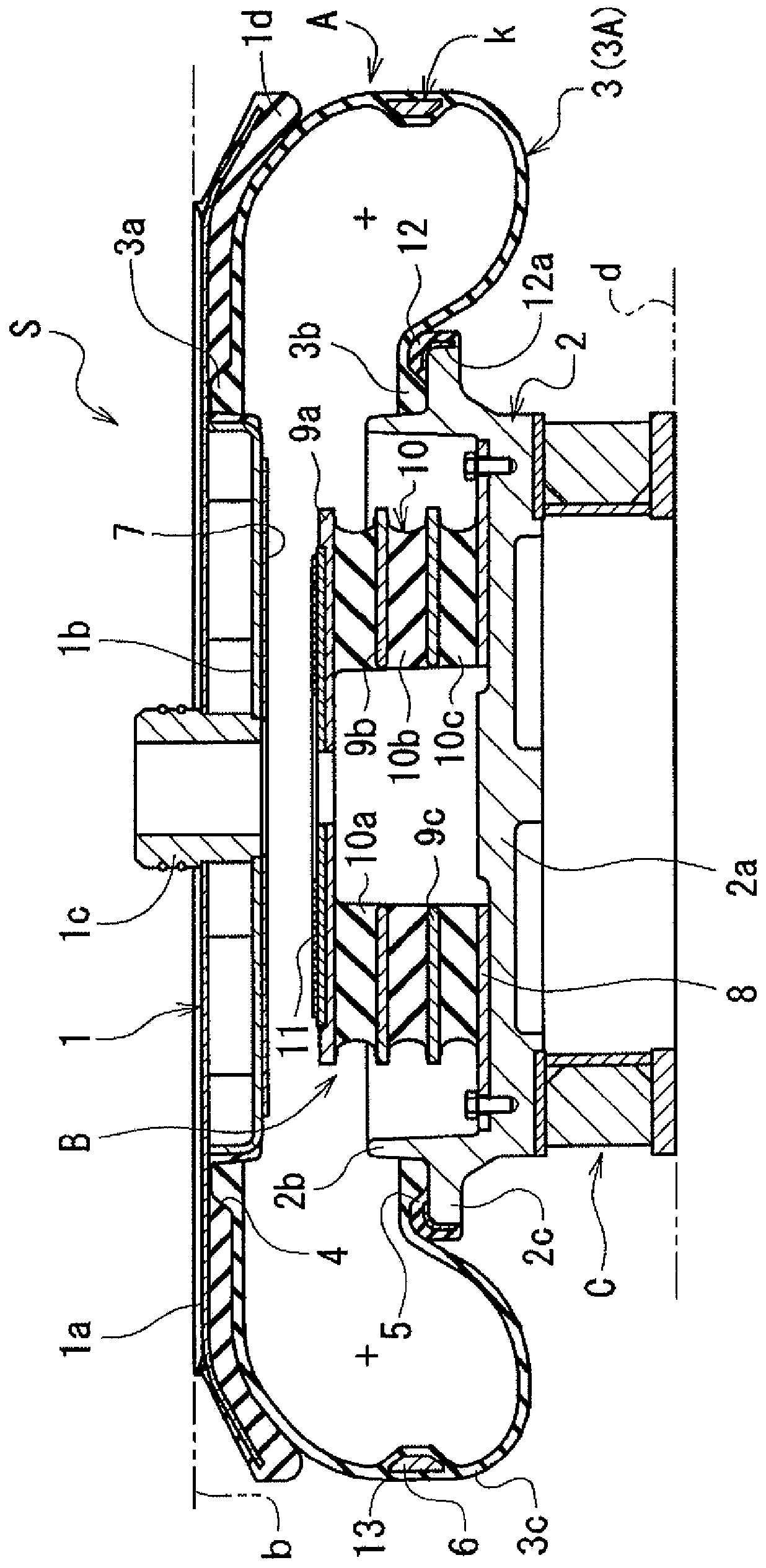

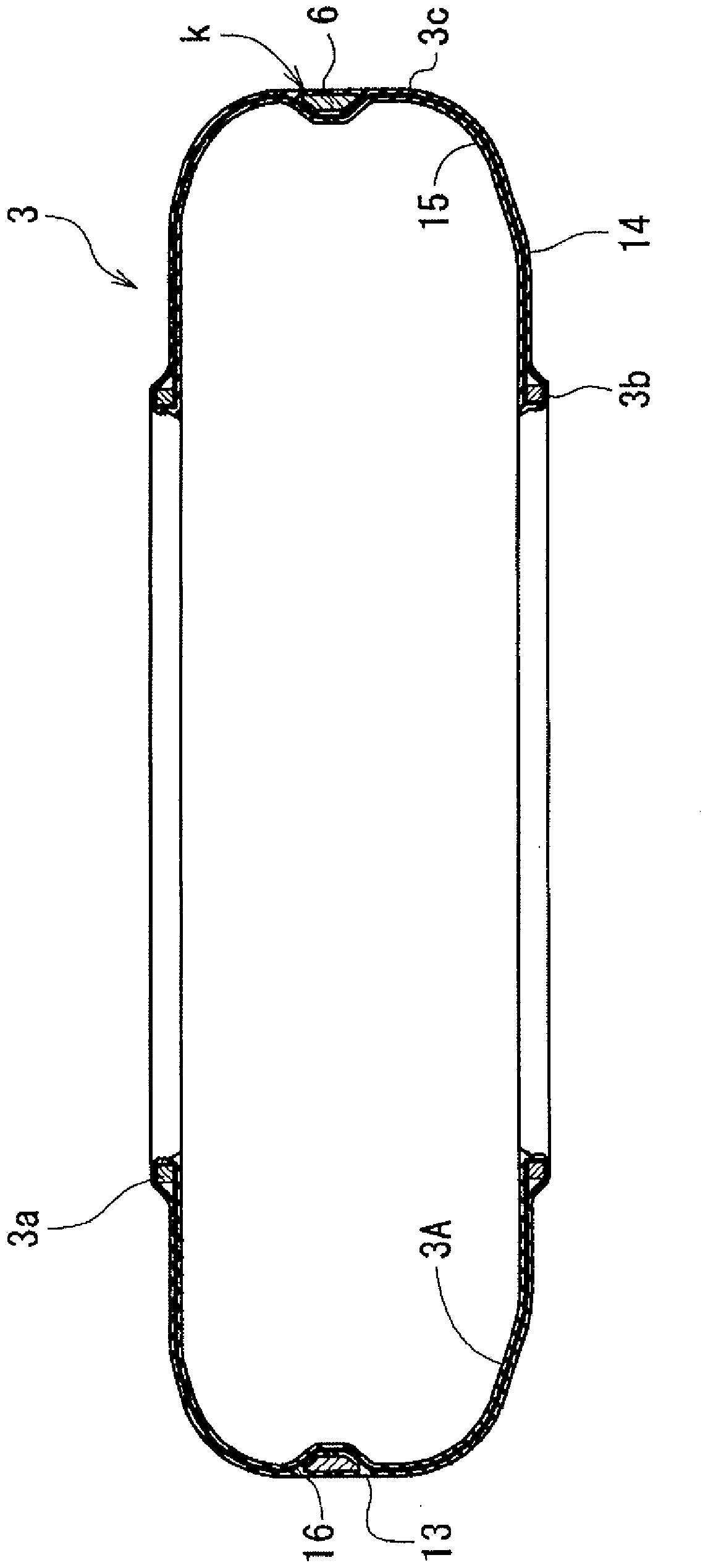

[0056] Hereinafter, the air spring A and the diaphragm 3 will be described in detail. Such as Figure 1-3 As shown, the constraining portion k in the air spring A is formed by embedding the reinforcing material 6 in the thick portion 13 formed by protruding and increasing the thickness of the elastic material forming the main body portion 3c radially inward.

[0057] The elastic material 3A forming the diaphragm 3 is an elastic film ( rubber film), and the thick wall portion 13 is formed by protruding and increasing the thickness of the outer rubber layer 14 inwardly in the radial direction, and the reinforcing material 6 is embedded in the thick wall portion 13 formed by the outer rubber layer 14 The state is set around.

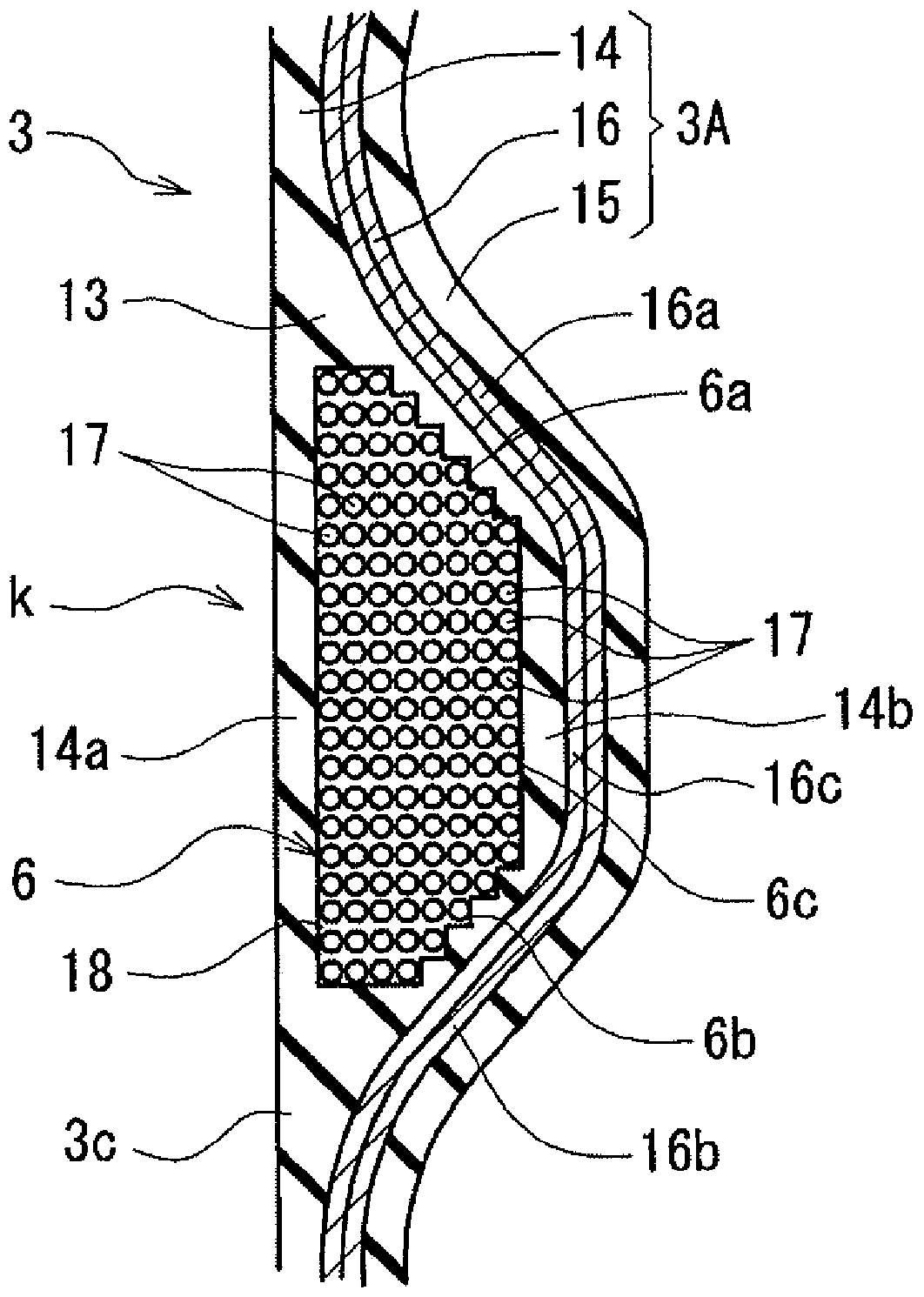

[0058] Such as image 3 As shown, the reinforcing material 6 is formed by covering a core material 17 formed of a ring-shaped or spiral-shaped metal material (steel) or the like in plan view and covered with a protective layer 18 formed of rubber or the ...

Embodiment approach 2

[0069] The diaphragm for an air spring and the air spring according to Embodiment 2 are only different from the constraining portion k in Embodiment 1, Figure 5 Indicates its main part.

[0070] Such as Figure 5 As shown, the binding portion k has a reinforcing material 6 with a rectangular cross section. In the radially inner side of the reinforcing material 6 , the positional relationship between the upper and lower corner portions 6 d , 6 e and the radially outer side surface of the reinforcing cord layer 16 of the diaphragm 3 is in contact with or very close to. Except that it is the same as diaphragm 3 (air spring A) in Embodiment 1, Figure 5 , the corresponding reference signs are marked on the corresponding places.

[0071] According to the diaphragm 3 (air spring A) of any of the embodiments, due to the presence of the constraining portion k, an effective outer diameter restricting action can be obtained. In addition, in the diaphragm 3 (air spring A) of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com