Installation and construction method of double-glass magnesium rock wool color steel plate

A technology of double-glass magnesia rock wool and construction method, which is applied in the processing of building materials, construction, building construction, etc., and can solve the problems of safety and hidden dangers in the partition board room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

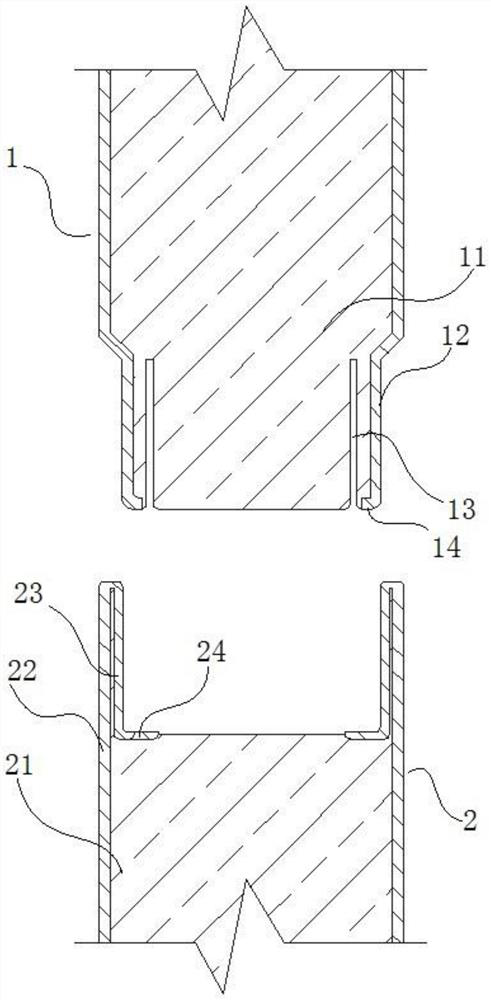

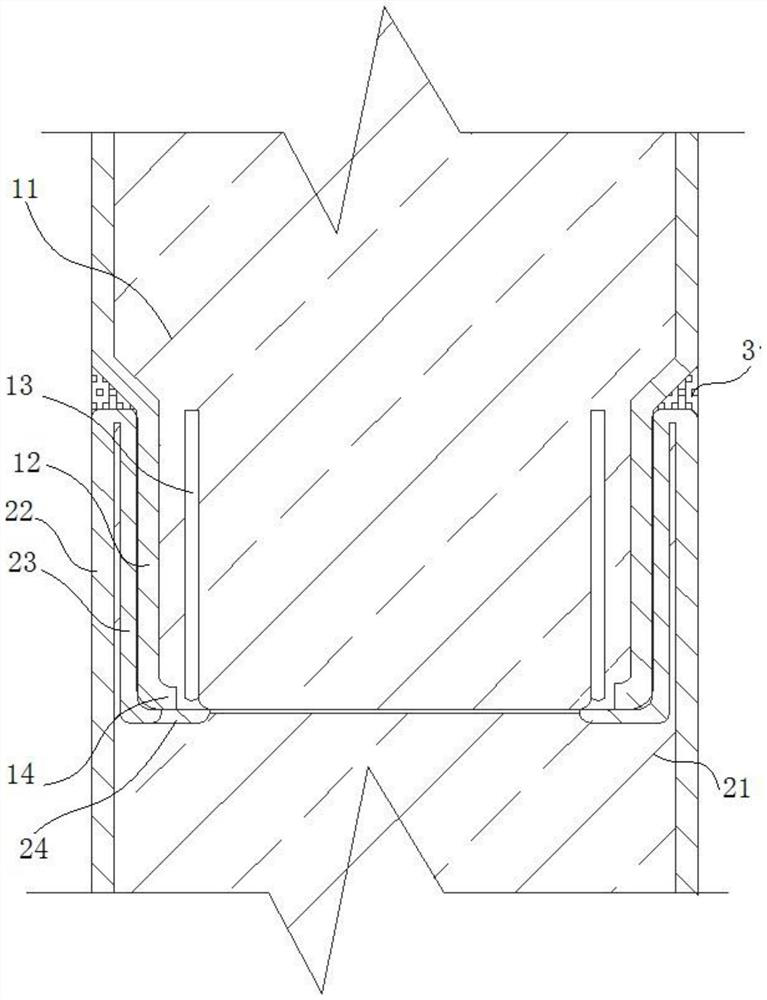

[0024] see Figure 1 to Figure 2 shown.

[0025] The installation and construction structure of a double-glass magnesia rock wool color steel plate of the present invention includes: a male joint 1 formed on one side of the double glass magnesia rock wool color steel plate and a male joint 1 formed on the other side of the double glass magnesia rock wool color steel plate 1 butted female connector 2;

[0026] The male joint 1 includes a glass magnesium rock wool layer A11, a color steel plate layer A12 bonded and fixed on both sides of the glass magnesium rock wool layer A11, pressure grooves 12 are provided on both sides of the connecting end of the glass magnesium rock wool layer A11, and the pressure The groove 13 has only an open surface facing the female joint 2, and the rest are closed surfaces;

[0027] The end connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com