Premixed flow state solidified soil foundation treatment construction method

A construction method and foundation treatment technology, which can be used in infrastructure engineering, soil protection, construction, etc., can solve problems such as poor vibration efficiency, and achieve the effects of promoting homogeneity, reducing construction time, and better disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

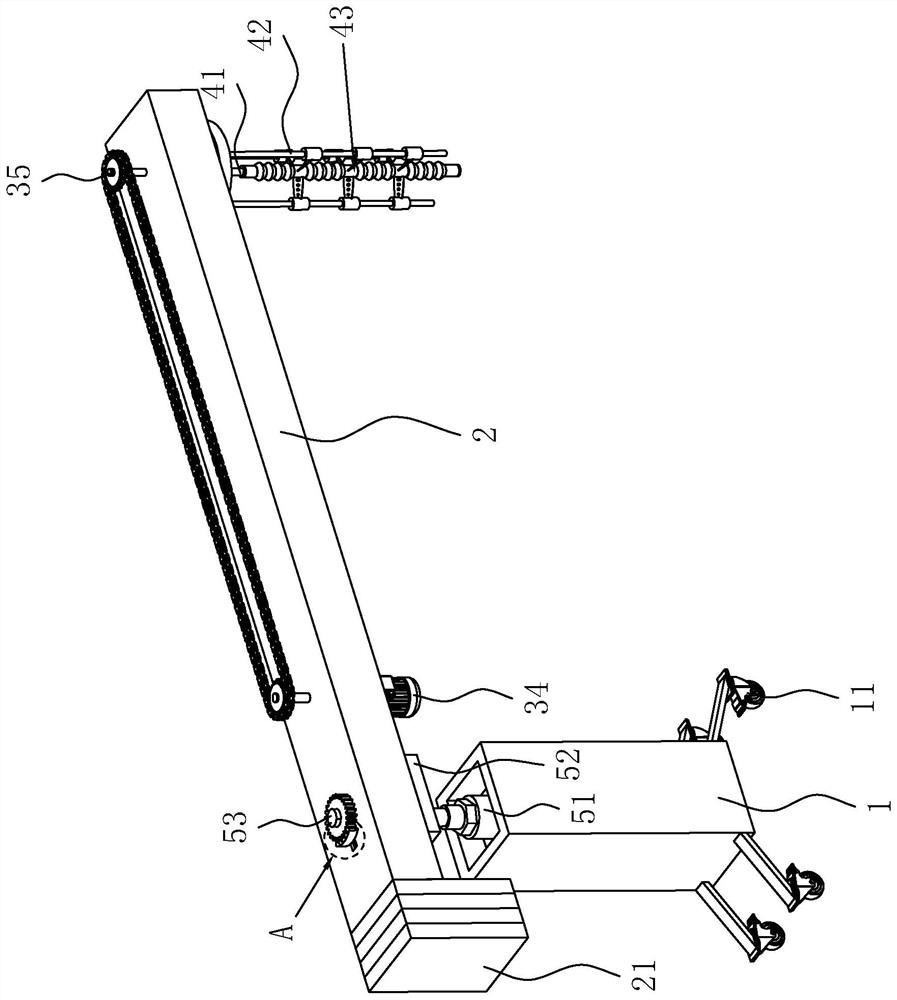

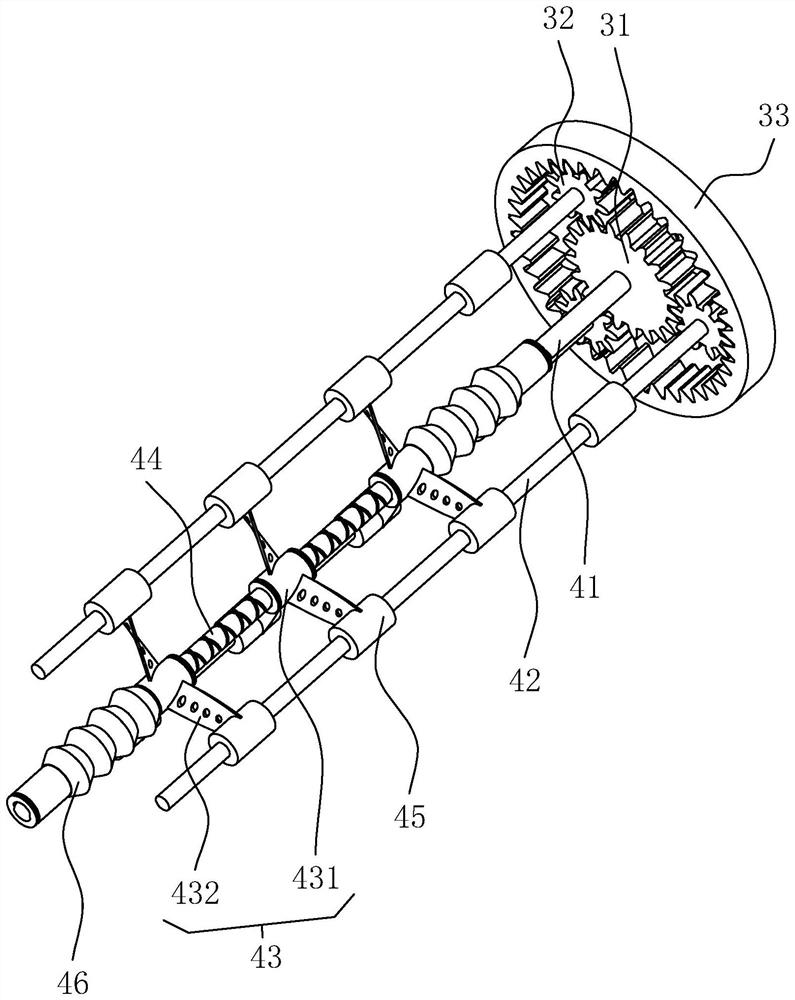

[0046] The following is attached Figure 1-4 The application is described in further detail.

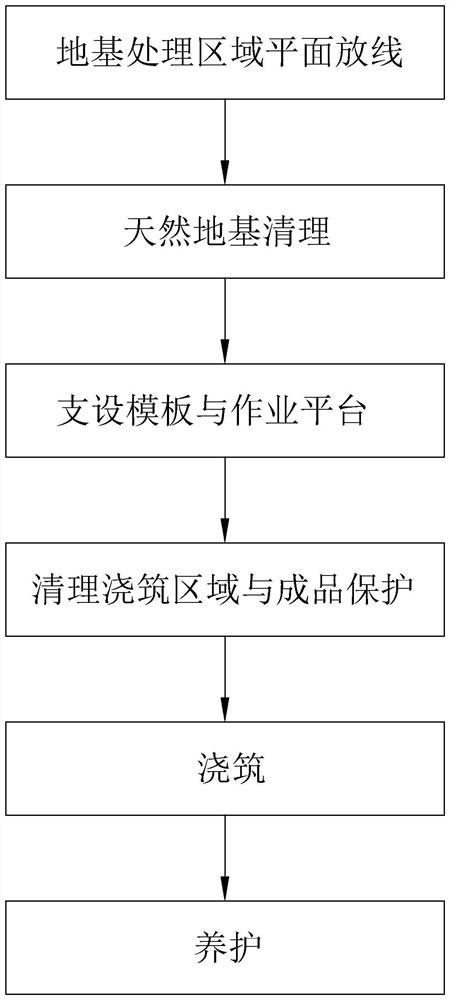

[0047] The embodiment of the present application discloses a construction method for pre-mixed fluid solidified soil foundation treatment. refer to figure 1 , the ready-mixed fluid solidified soil foundation treatment construction method comprises the following steps:

[0048] S1. Plane laying out of the foundation treatment area. The surveyors arrange the positioning control piles, elevation level piles and the gray line size of the groove at the foundation treatment position according to the plane control network of the site and the foundation treatment construction plan. Elevation control lines are set on the outer wall of the completed structure or on the surface of the formwork to strictly control the pouring elevation and flatness.

[0049] S2. Natural foundation cleaning, excavation treatment of the natural foundation with too weak bearing capacity.

[0050] S3. Support fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com