Method for bioelectrocatalytic reduction of carbon dioxide by mesoporous material immobilized enzyme and application

A technology of mesoporous materials and immobilized enzymes, applied in biochemical equipment and methods, immobilized enzymes, oxidoreductases, etc., can solve the problems of expensive coenzyme NADH, low solubility, unfavorable reaction conversion, easy inactivation, etc., to achieve Effect of promoting CO2 reduction reaction, reducing coenzyme consumption, and maintaining enzyme activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

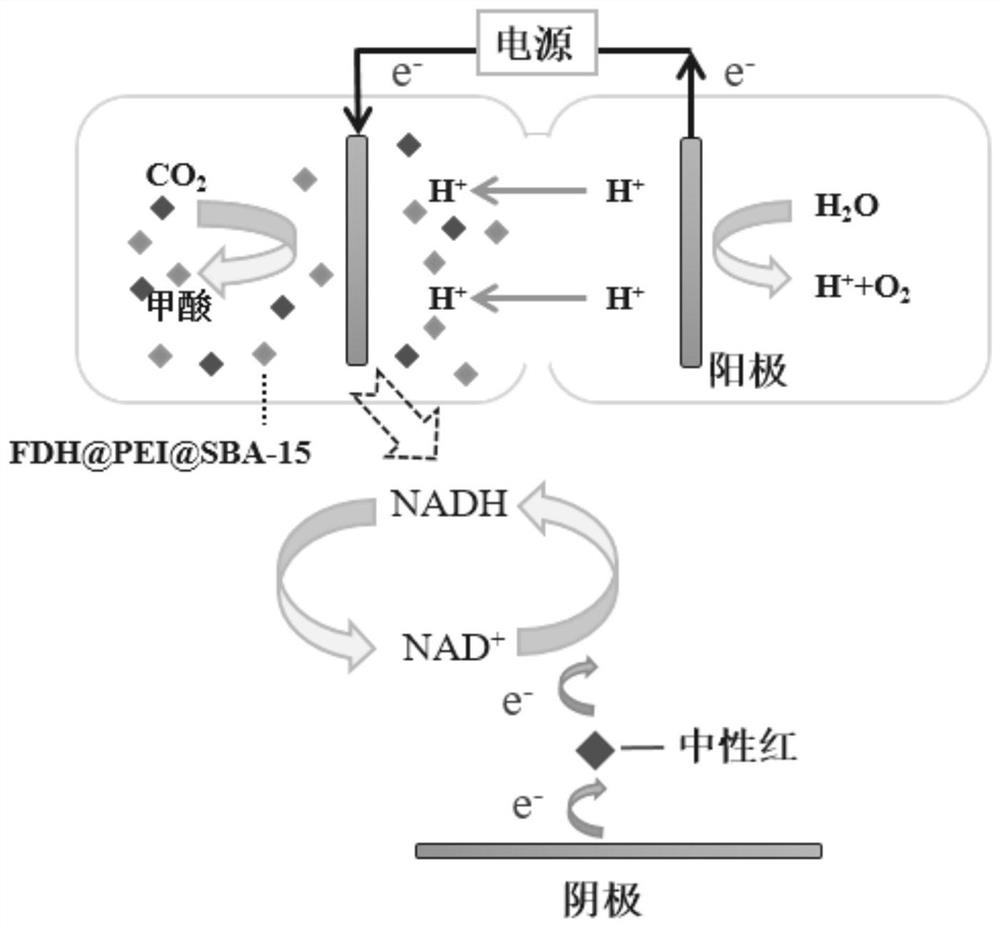

[0025] bioelectrocatalytic CO 2 To restore, the steps are as follows:

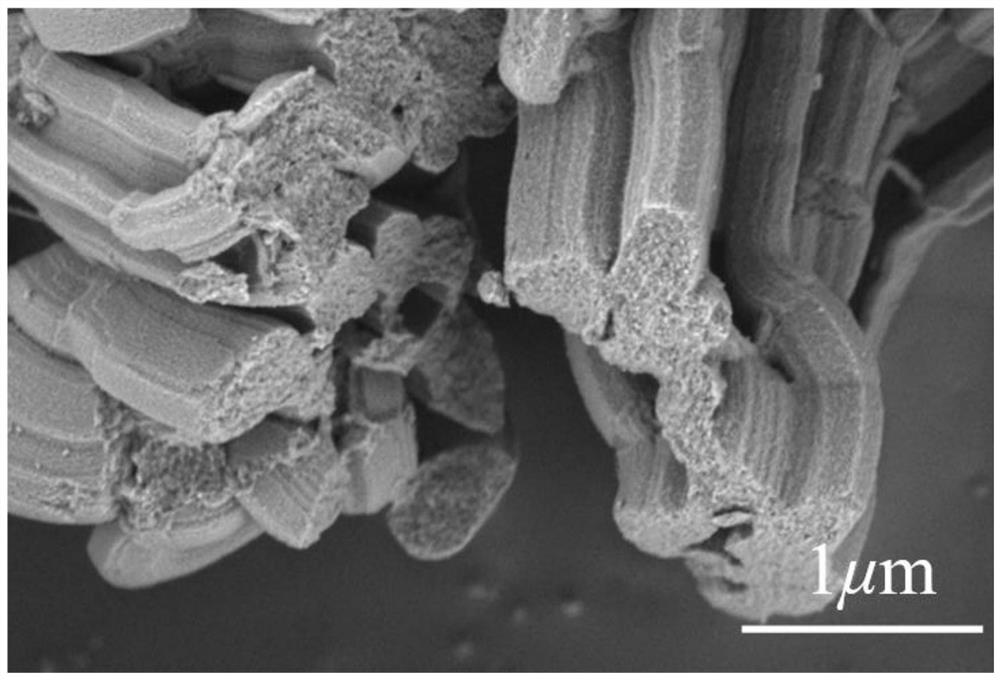

[0026] Step 1) Weigh 1 g of commercial mesoporous material SBA-15 into a 100 mL single-necked flask, add 30 mL of anhydrous toluene, and ultrasonically disperse to form a homogeneous solution. Then, slowly add 1 mL of silane coupling agent 3-aminopropyltriethoxysilane (APTES) into the homogeneous solution, stir at 110° C., condense and reflux for 24 hours. The reaction solution was cooled to room temperature, centrifuged, washed three times with absolute ethanol to remove the unreacted silane coupling agent, and then dried in an oven at 60°C overnight to obtain an APTES-modified mesoporous material.

[0027] Step 2) Weigh 0.3 g of the APTES-modified mesoporous material prepared in step 1) and place it in a 100 mL one-necked flask, add 10 mL of phosphate buffer, and disperse by ultrasonication. Add 1 mL of glutaraldehyde solution to the above solution and stir, then add 30 mL of 100 mM phosphate buffer co...

Embodiment 2

[0035] bioelectrocatalytic CO 2 Reduction, the specific steps are basically the same as in Example 1, except that in step b), 100 mM phosphate buffer containing 0.09 g PEI is added, so that the mass ratio of PEI to SBA-15 is 30%.

[0036] Figure 4 is the CO of SBA-15 under different amounts of PEI modification 2 Temperature-programmed desorption characterization diagram, it can be seen that after PEI modification, the mesoporous material has a 2 The adsorption capacity increased significantly.

[0037] Using Example 2 for bioelectrocatalytic CO 2 Reduction, the concentration of formic acid produced after 180 minutes of testing is 0.88mM.

Embodiment 3

[0039] bioelectrocatalytic CO 2 Reduction, the specific steps are basically the same as in Example 1, except that 100 mM phosphate buffer containing 0.24 g PEI is added in step b), so that the mass ratio of PEI to SBA-15 is 80%.

[0040] Using Example 3 for bioelectrocatalytic CO 2 Reduction, the concentration of formic acid produced after testing for 180min is 1.10mM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com