Mounting and fixing process for PVC pipe transportation

A PVC pipe and process technology, applied in the field of installation and fixation technology for PVC pipe transportation, can solve the problems of fixed size of pipe transfer frame, inability to apply PVC pipes of various lengths, and inability to adjust the height of different transport vehicles, etc. Achieve the effect of improving transportation and installation efficiency, convenient stacking, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

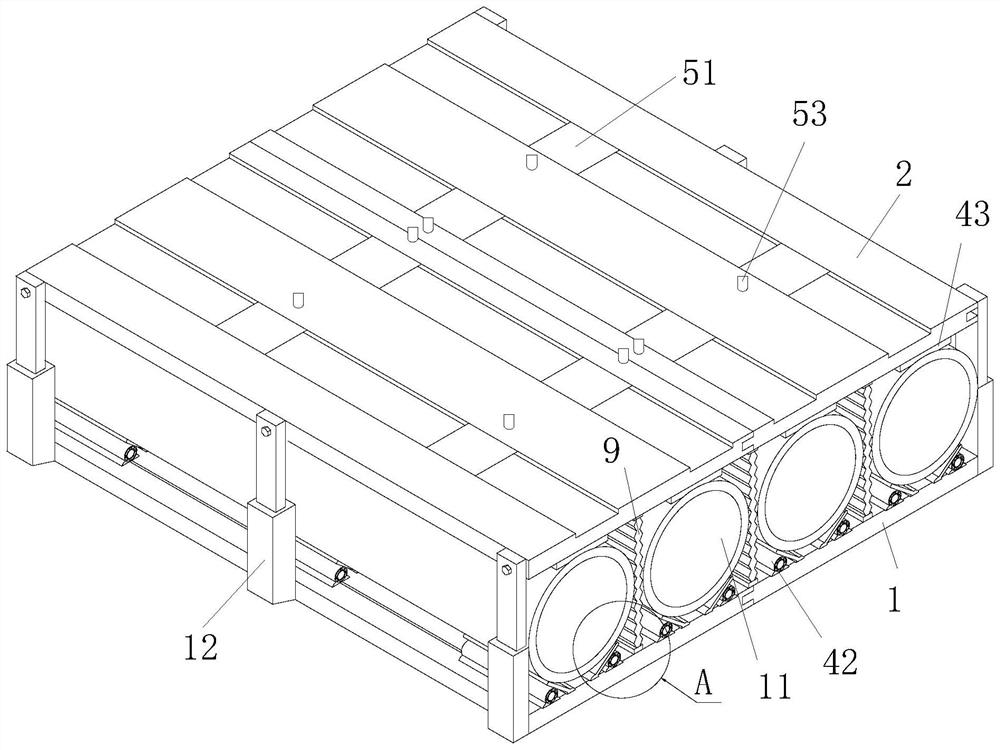

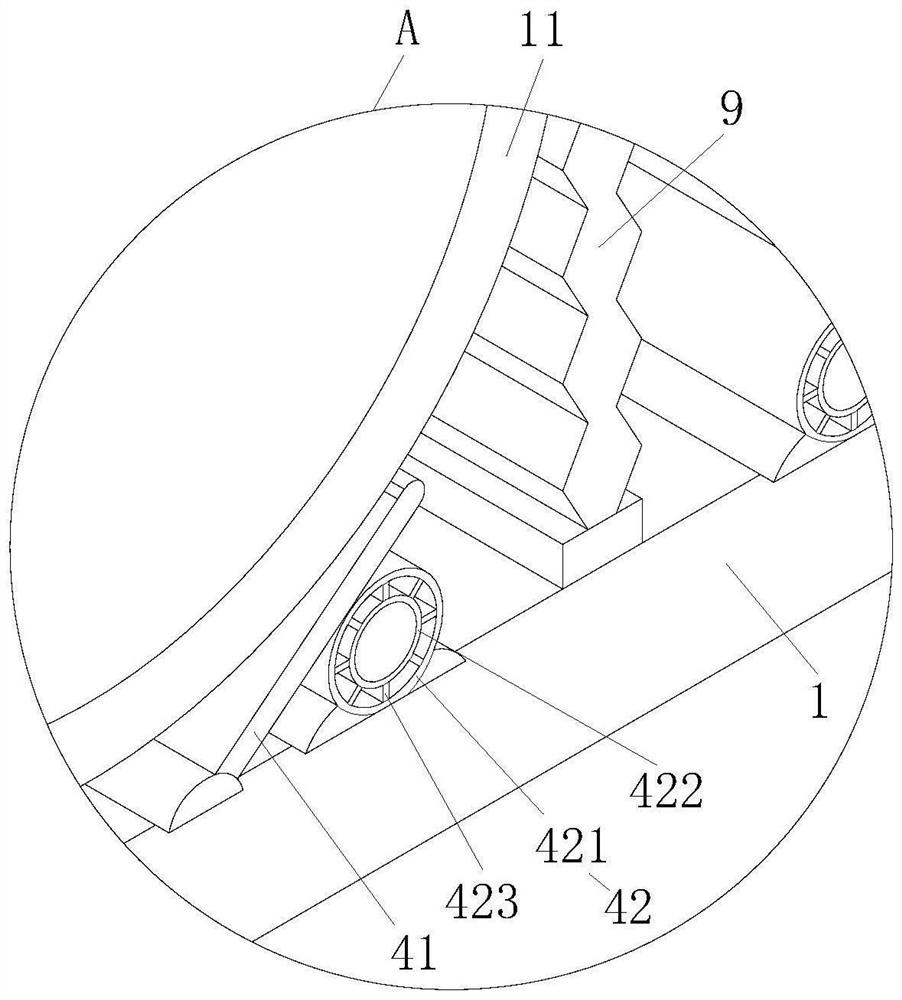

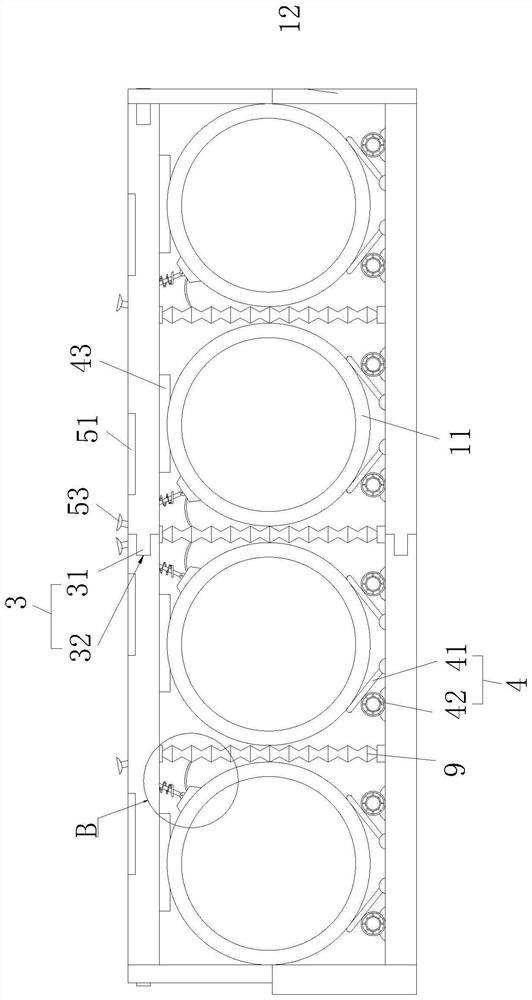

[0038] Attached below Figure 1-7 The present invention is further described with embodiment:

[0039] An installation and fixing process for PVC pipe transportation, comprising the following steps:

[0040] A, determine the transport vehicle, determine the required transport vehicle according to the length of the transported pipe body 11, and determine the quantity to be transported according to the height, width and length of the transport vehicle compartment;

[0041] B. Install the transfer installation device, first assemble the frame body, then place the pipe body 11 to be transported on the adaptation mechanism 4, then control the electric lifting rod 12 to adjust the distance between the bottom frame plate 1 and the top frame plate 2, and adjust the distance between the tube body 1 and the top frame plate 2. body 11 to limit the position;

[0042] C. Hoisting, hoisting the installed frame body into the box, then superimposing the frame body according to the height of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com