Brass rod surface anti-skid pattern engraving equipment

A brass rod and anti-slip technology, which is applied in the field of anti-slip marking equipment on the surface of brass rods, can solve the problems that brass rods are prone to shaking, and achieve the effect of convenient operation and preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

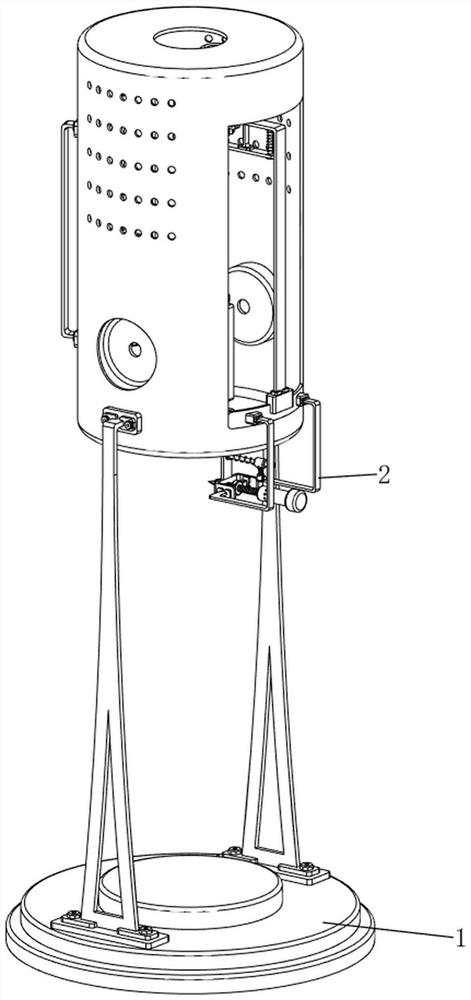

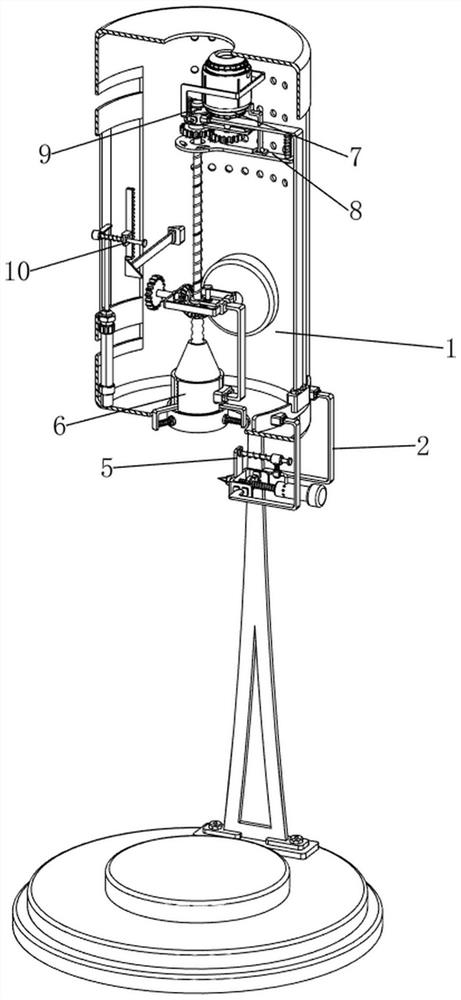

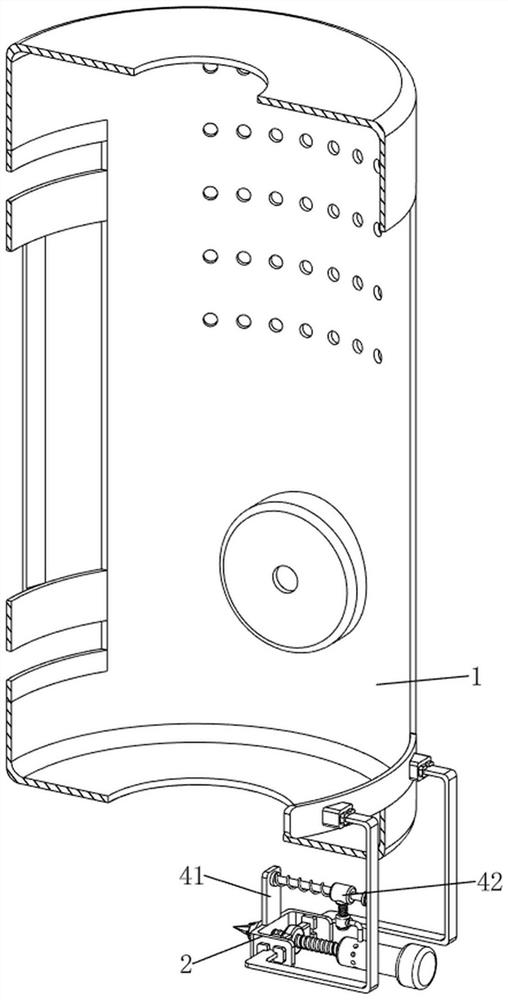

[0040] A device for engraving anti-slip patterns on the surface of brass rods, such as Figure 1-Figure 11As shown, it includes a connecting frame 1, a first connecting rod 2, a nut block 3, a scraper 301, a locking mechanism 4, a scratching mechanism 5 and a rotating mechanism 6, and the upper right side of the connecting frame 1 is welded with the first connecting rod. 2. There is a nut block 3 on the left side of the lower part of the first connecting rod 2, and a thread scraper 301 is provided on the inner side of the nut block 3. After the scraper 301 contacts the brass rod, when the brass rod rotates, it can The copper bar is used for engraving, and the scraper 301 passes through the lower left side of the first connecting rod 2. The first connecting rod 2 is provided with a locking mechanism 4, and the connection frame 1 is provided with a scraping mechanism 5. A rotating mechanism 6 is provided.

[0041] The clamping mechanism 4 includes a second connecting rod 41, a ...

Embodiment 2

[0046] On the basis of Example 1, such as figure 2 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 and Figure 17 As shown, an opening mechanism 7 is also included, and the opening mechanism 7 includes a second driving rod 71, a fourth connecting rod 72, a movable ring 73, a third driving rod 74 and a fourth spring 75, and the left side of the third connecting rod 53 top A second driving rod 71 is provided, a fourth connecting rod 72 is welded on the right side of the upper part of the nut rod 51, and a movable ring 73 is provided on the lower side of the fourth connecting rod 72 slidingly, and a third driving rod 74 is arranged on the right side of the top of the movable ring 73 , the third driving rod 74 can automatically control the output shaft of the motor 61 to reverse when it is in contact with the switch. There is a fourth spring 75 wound on the fourth connecting rod 72 .

[0047] When the third connecting rod 53 moved upward, the third connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com