Production method of salted egg yolk

A production method and technology of salted egg yolk, applied in the production field of salted egg yolk, can solve the problems such as difficulty in controlling salt concentration, pickling time and pickling temperature, cracking of salted egg yolk when baking, poor taste of salted egg yolk, etc. Insufficient marinating, rich taste, good taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

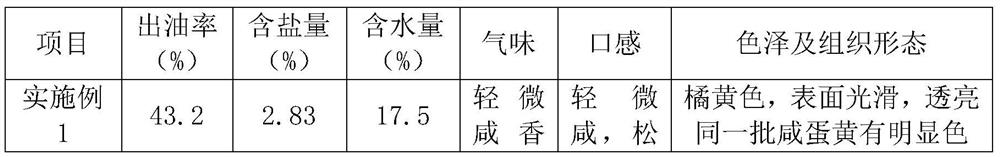

Embodiment 1

[0074] Present embodiment provides a kind of production method of salted egg yolk, comprises the following steps:

[0075] S100: Spray and scrub the surface of raw duck eggs, air-dry, and sterilize with ultraviolet light;

[0076] S200: Pickle the treated raw duck eggs through a grouting and pickling process; wherein, the grouting and pickling process is to put the salted eggs into a container, pour the marinade and cover the upper layer of raw duck eggs;

[0077] S300: marinate the selected raw duck eggs in a marinade for 60 days at 10°C to obtain salted duck eggs; the specific mass ratio of the marinade is: salt:water:yellow mud=2:1:1.14;

[0078] S400: cleaning the yellow mud on the surface of the salted duck eggs, and picking out the damaged salted duck eggs;

[0079] S500: breaking the salted duck eggs to separate the salted egg yolk from the egg white;

[0080] S600: Centrifugally clean the salted egg yolk and bake; wherein, the baking temperature of the baking is 50°C...

Embodiment 2

[0083] Present embodiment provides a kind of production method of salted egg yolk, comprises the following steps:

[0084] S100: Spray and scrub the surface of raw duck eggs, air-dry, and sterilize with ultraviolet light;

[0085] S200: Pickle the treated raw duck eggs through a grouting and pickling process; wherein, the grouting and pickling process is to put the salted eggs into a container, pour the marinade and cover the upper layer of raw duck eggs;

[0086] S300: marinate the selected raw duck eggs in a marinade for 60 days at 10°C to obtain salted duck eggs; the specific mass ratio of the marinade is: salt:water:yellow mud=2:1:1.14;

[0087] S400: cleaning the yellow mud on the surface of the salted duck eggs, and picking out the damaged salted duck eggs;

[0088] S500: breaking the salted duck eggs to separate the salted egg yolk from the egg white;

[0089] S600: Centrifugally clean the salted egg yolk and bake; wherein, the baking temperature of the baking is 50°C...

Embodiment 3

[0092] Present embodiment provides a kind of production method of salted egg yolk, comprises the following steps:

[0093] S100: Spray and scrub the surface of raw duck eggs, air-dry, and sterilize with ultraviolet light;

[0094] S200: Pickle the treated raw duck eggs through a grouting and pickling process; wherein, the grouting and pickling process is to put the salted eggs into a container, pour the marinade and cover the upper layer of raw duck eggs;

[0095] S300: marinate the selected raw duck eggs in a marinade for 60 days at 10°C to obtain salted duck eggs; the specific mass ratio of the marinade is: salt:water:yellow mud=2:1:1.14;

[0096] S400: cleaning the yellow mud on the surface of the salted duck eggs, and picking out the damaged salted duck eggs;

[0097] S500: breaking the salted duck eggs to separate the salted egg yolk from the egg white;

[0098] S600: centrifugally cleaning the salted egg yolk and toasting; wherein, the baking temperature of the toastin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com