Preparation method and application of porous carbon fiber/tungsten oxide self-supporting lithium-sulfur battery positive electrode material

A porous carbon fiber, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, positive electrodes, etc., can solve the problems of reducing active sulfur utilization, electron/ion kinetic performance, reducing battery energy density, increasing electrode internal resistance, etc. , to achieve the effect of shortening the electron/ion transmission path, excellent conductivity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of a porous carbon fiber / tungsten oxide self-supporting lithium-sulfur battery cathode material in this example is as follows:

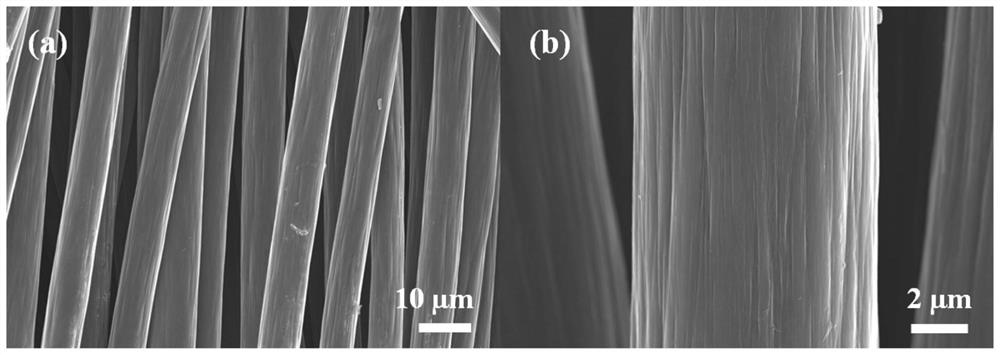

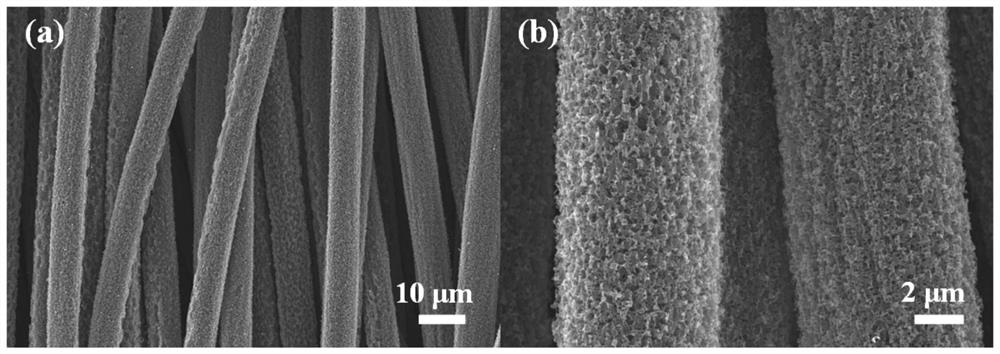

[0037] 1. Commercial carbon cloth (CC) was ultrasonically treated with acetone, ethanol, and deionized water for 10 minutes, and dried at 60°C for 10 hours. CC was used as the working electrode, Pt was used as the counter electrode, and Ag / AgCl was used as the reference electrode. A three-electrode system was used. Electrodeposit nickel hydroxide, dry at 60°C for 10 hours, then reduce in nitrogen at 800°C at high temperature, heating rate 5°C / min, keep warm for 4 hours, then pickle with 3M hydrochloric acid for 6 hours, wash and dry to obtain porous carbon fiber cloth PCC;

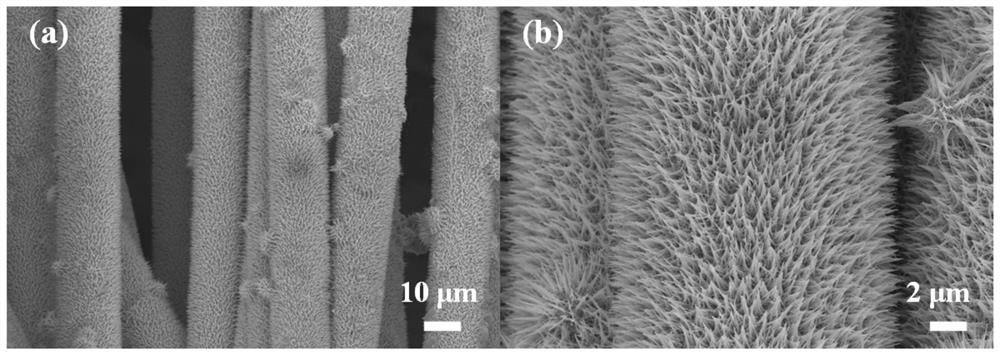

[0038] 2. Weigh 1.75g (NH 4 ) 2 SO 4 , added to 30mL precursor solution containing tungsten source, wherein the precursor solution is 0.125MNaWO 4 and 0.1M H 2 C 2 o 4 After stirring the mixed solution for 1 hour, put the PCC obtained in Step...

Embodiment 2

[0052] The preparation method of a porous carbon fiber / tungsten oxide self-supporting lithium-sulfur battery cathode material in this example is as follows:

[0053] 1. Commercial carbon cloth (CC) was ultrasonically treated with acetone, ethanol, and deionized water for 10 minutes, and dried at 60°C for 10 hours. CC was used as the working electrode, Pt was used as the counter electrode, and Ag / AgCl was used as the reference electrode. A three-electrode system was used. A layer of nickel hydroxide was electrodeposited, dried at 60°C for 10 hours, then reduced in nitrogen at 800°C at a high temperature, the heating rate was 5°C / min, kept for 4 hours, then pickled with 3M hydrochloric acid for 6 hours, washed and dried to obtain porous carbon fiber cloth PCC;

[0054] 2. Weigh 1.75g (NH 4 ) 2 SO 4 , added to 30mL precursor solution containing tungsten source, wherein the precursor solution is 0.125MNaWO 4 and 0.1M H 2 C 2 o 4 After stirring the mixed solution for 1 hour...

Embodiment 3

[0058] The preparation method of a carbon fiber / tungsten oxide self-supporting lithium-sulfur battery cathode material in this embodiment is as follows:

[0059] 1. Commercial carbon cloth (CC) was ultrasonically treated with acetone, ethanol, and deionized water for 10 minutes, and dried at 60°C for 10 hours.

[0060] 2. Weigh 1.75g (NH 4 ) 2 SO 4 , added to 30mL precursor solution containing tungsten source, wherein the precursor solution is 0.125MNaWO 4 and 0.1M H 2 C 2 o 4 After stirring the mixed solution for 1 hour, arrange the carbon obtained in step 1 in the precursor solution, then transfer it to the reaction kettle, and conduct a hydrothermal reaction at 160°C for 8 hours. After the reaction, wash repeatedly, and dry at 60°C for 10 hours to obtain The carbon fiber cloth with tungsten oxide precursor grown on the surface is sent to a tube furnace for annealing treatment. Under an argon protective atmosphere, the temperature is kept at 400°C for 3 hours, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com