Precise automatic traction device of spinning frame for rotary hot roller yarn guide

A traction device and rotary technology, applied in the field of spinning and spinning, can solve problems such as damage to equipment, adverse effects of equipment operation, and impact on the production environment, and achieve the effects of improving quality, avoiding real-time detection, and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

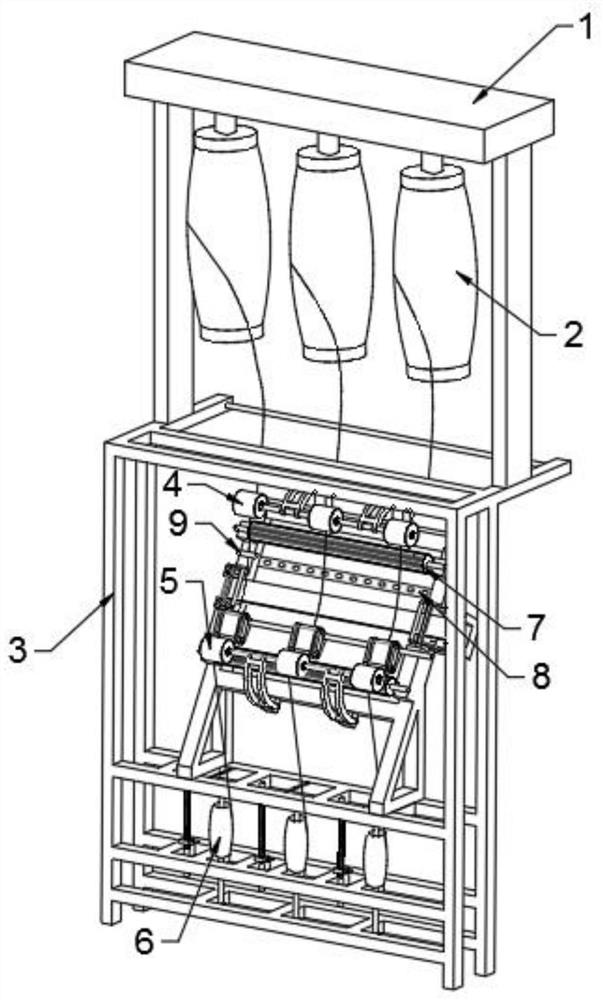

[0042] See Figure 1-2 According to the present invention, it provides a technical solution: a fine air blowing device for rotary heat roller, including a stent 3, characterized in that the top plate 1 is fixedly mounted with a top plate 1, and the lower bearing of the top plate 1 is connected to a coarse cylinder 2. The surface of the roving cylinder 2 is wound with a rough yarn, and there is a rear leather roller 4 and the front skin roller 5, the rear leather roller 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com