Mulching film and drip irrigation belt integrated intelligent laying system

A technology of drip irrigation tape and mulch, which is applied in the field of agricultural equipment, can solve the problems of high work intensity, low laying efficiency, time-consuming and laborious, etc., and achieve the effect of enhancing wind resistance, maintaining flatness, and avoiding tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

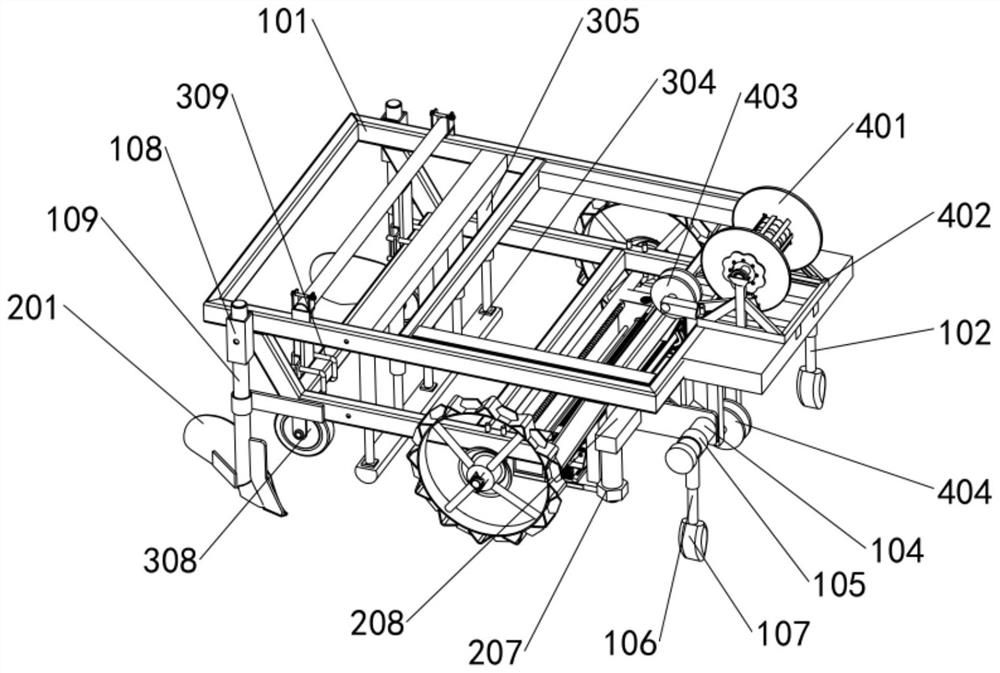

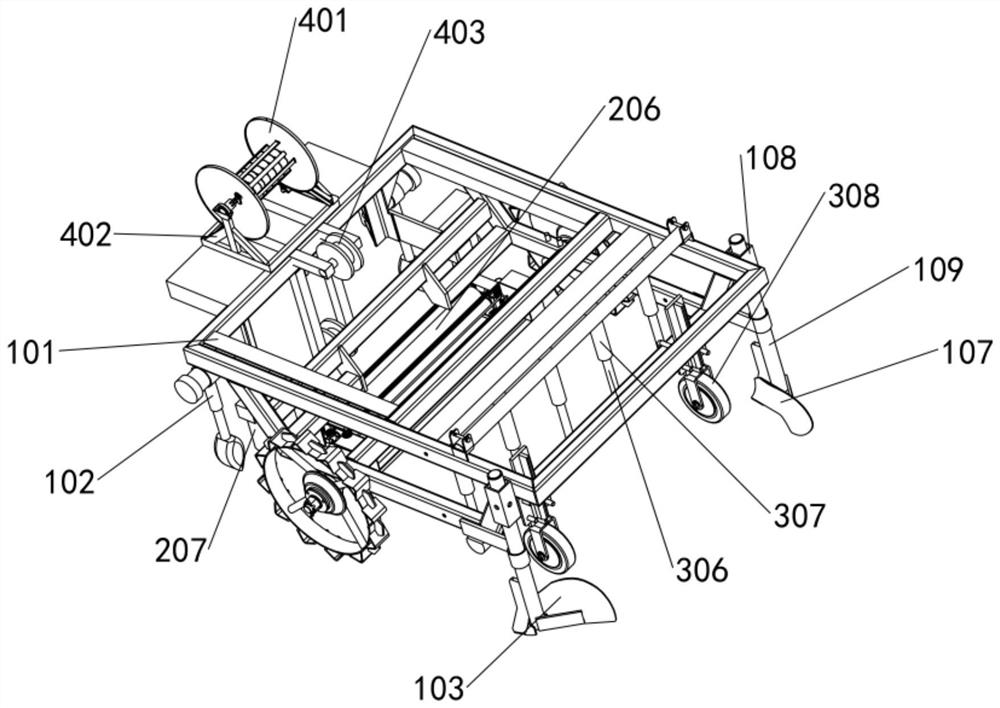

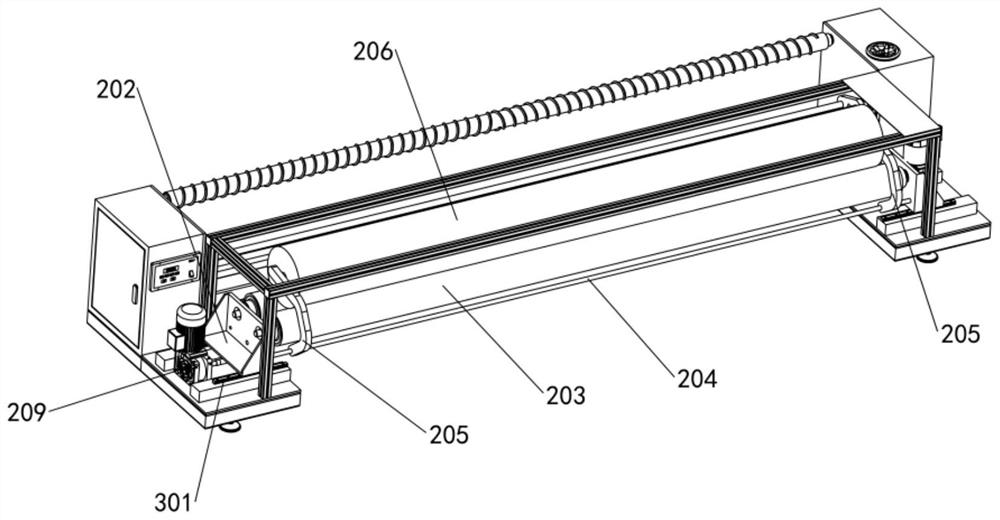

[0039] An integrated intelligent laying system of mulch film and drip irrigation tape, including a frame 101 and a mulch film laying component and a drip irrigation tape laying component installed on the frame 101;

[0040] Such as figure 1 , 2As shown, the two sides of the front end of the frame 101 are provided with a soil-turning mechanism 102, and the two sides of the rear end of the frame 101 are provided with a soil-covering mechanism 103. The soil-turning mechanism 102 is used for laying on the ground before the film Two ditches are opened, and the soil covering mechanism 103 is used to lay the soil on the sides of the two ditches on the plastic film;

[0041] The soil turning mechanism 102 is connected with the frame 101 through the second fixed rod 104, the soil turning mechanism 102 includes a collar 105, and the collar 105 is slidably sleeved on the second fixed rod 104. A telescopic rod 106 is fixedly connected to the bottom of the collar 105, and a ditching plow...

Embodiment 2

[0058] The second aspect of the present invention provides a control method for an integrated intelligent laying system of mulch film and drip irrigation tape, which is applied to any one of the above-mentioned integrated intelligent laying systems of mulch film and drip irrigation tape, including the following steps:

[0059] Receive the laying task sent by the outside, the laying task includes the laying operation area information, calculate the laying path and the total amount of the plastic film and the drip irrigation belt in combination with the laying operation area information, and set the working parameters of the control system;

[0060] Send the laying path to the control system, combined with the current rack position information, the control system controls the drive mechanism to move the rack to the starting point of the laying path;

[0061]When the frame moves to the starting point of the laying path, a laying start signal is sent to the control system, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com