Preparation method of friction nano-generator based on super-slip surface

A nanogenerator, slip technology, applied in triboelectric generators, devices for coating liquids on surfaces, special surfaces, etc., can solve problems such as TENG failure, and achieve the effects of overcoming failure, excellent stability, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing triboelectric nanogenerators (SLIPSs-TENG) based on super-slip surfaces, comprising the following steps:

[0028] ⑴ Preparation of triboelectrode:

[0029] ① Dilute the polytetrafluoroethylene (PTFE) dispersion with a concentration of 10~60wt% at 0.02~0.04mL / cm 2 Spin coating onto the cleaned support substrate yielded a PTFE-coated substrate. The material of the supporting base refers to one of aluminum, nickel, copper, silver, gold and platinum.

[0030] ②Heating the PTFE-coated substrate at 300° C. for 2 hours to remove the surfactant in the PTFE dispersion to prepare the supporting layer 2 coated with the solid friction material.

[0031] ③According to 0.002~0.004mL / cm 2 Lubricating oil is drop-coated on the supporting layer 2 coated with the solid friction material, and the lubricating oil refers to one of perfluoropolyether (PFPE), silicone oil, and mineral oil. The lubricating oil is immiscible with friction fluids. The excess lubricati...

Embodiment 1

[0040] Embodiment 1 A preparation method of SHBs-TENG comprises the following steps:

[0041] ⑴ Preparation of triboelectrode:

[0042] ① Dilute the polytetrafluoroethylene (PTFE) dispersion with a concentration of 60wt% at 0.032mL / cm 2 Spin coating onto cleaned aluminum sheets to obtain PTFE-coated substrates;

[0043] ②The PTFE-coated substrate was heated at 300°C for 2 hours to remove the surfactant in the PTFE dispersion, and a triboelectrode based on a hydrophobic surface was prepared.

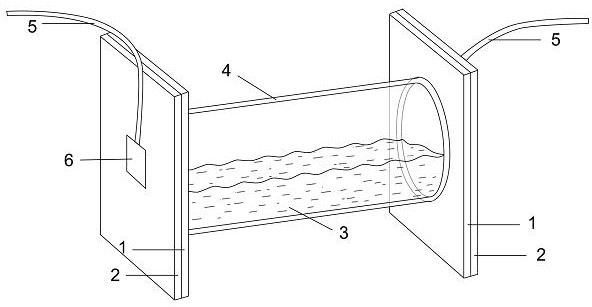

[0044] (2) Encapsulate two identical friction electrodes on both sides of the plastic tube 4; the plastic tube 4 is a PC tube with an outer diameter of 2 cm, an inner diameter of 1.8 cm, and a length of 6 cm.

[0045] (3) Inject 5 mL of friction liquid 3 into plastic tube 4, friction liquid 3 is deionized water.

[0046] (4) Use conductive tape 6 to fix the metal wire 5 on the outside of the friction electrode to obtain SHBs-TENG. The conductive tape 6 is a copper tape; the metal wire...

Embodiment 2

[0047]Example 2 A preparation method of SLIPSs-TENG, comprising the following steps:

[0048] ⑴ Preparation of triboelectrode:

[0049] ① Dilute the polytetrafluoroethylene (PTFE) dispersion with a concentration of 60wt% at 0.032mL / cm 2 Spin coating onto cleaned aluminum sheets to obtain PTFE-coated substrates;

[0050] ②Heating the PTFE-coated substrate at 300°C for 2 hours to remove the surfactant in the PTFE dispersion to prepare the supporting layer 2 coated with the solid friction material of the triboelectrode;

[0051] ③According to 0.0032mL / cm 2 The lubricating oil (PFPE) was drip-coated on the support layer 2, and the excess lubricating oil droplets were removed by spin-coating to obtain a triboelectrode based on a super-slip surface.

[0052] (2) Encapsulate two identical triboelectrodes based on the super-slip surface on both sides of the plastic tube 4; the plastic tube 4 is a PC tube with an outer diameter of 2 cm, an inner diameter of 1.8 cm, and a length of 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com