Permanent magnet ring, motor applying permanent magnet ring and manufacturing method and mold

A manufacturing method and technology of permanent magnet rings, which are applied in the manufacture of inductors/transformers/magnets, motor generators, stator/rotor bodies, etc., can solve the problems of complex structure, difficult assembly and operation, and heavy motor rotors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

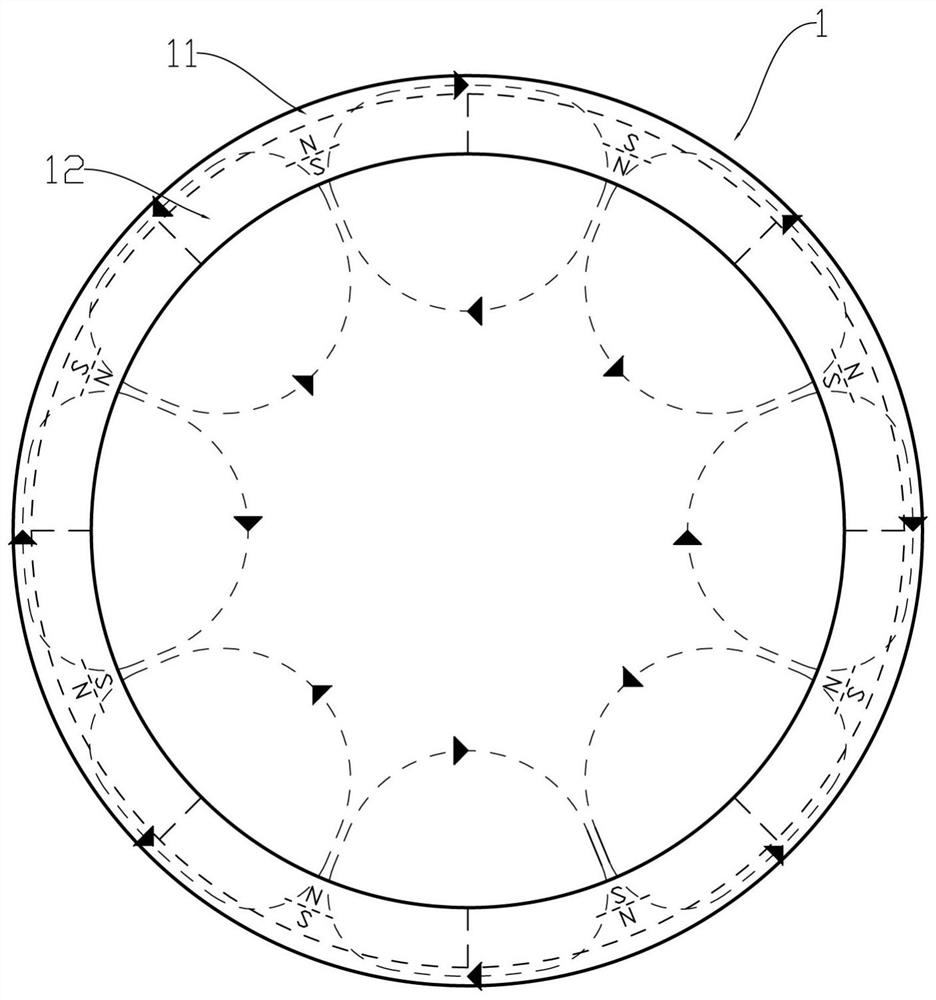

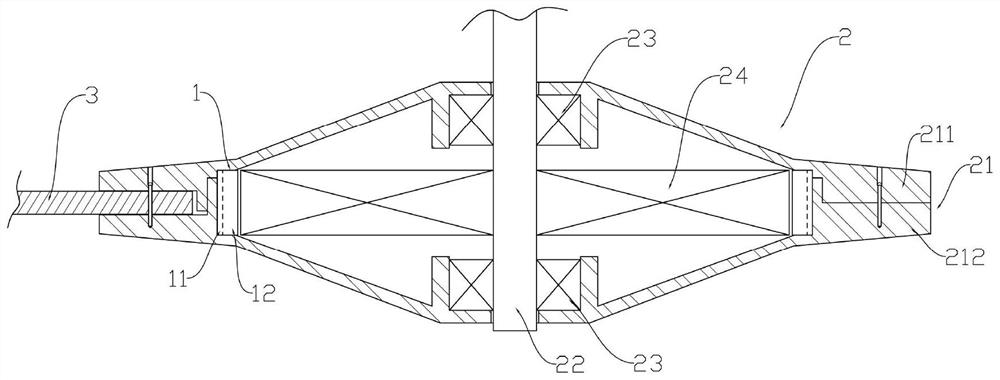

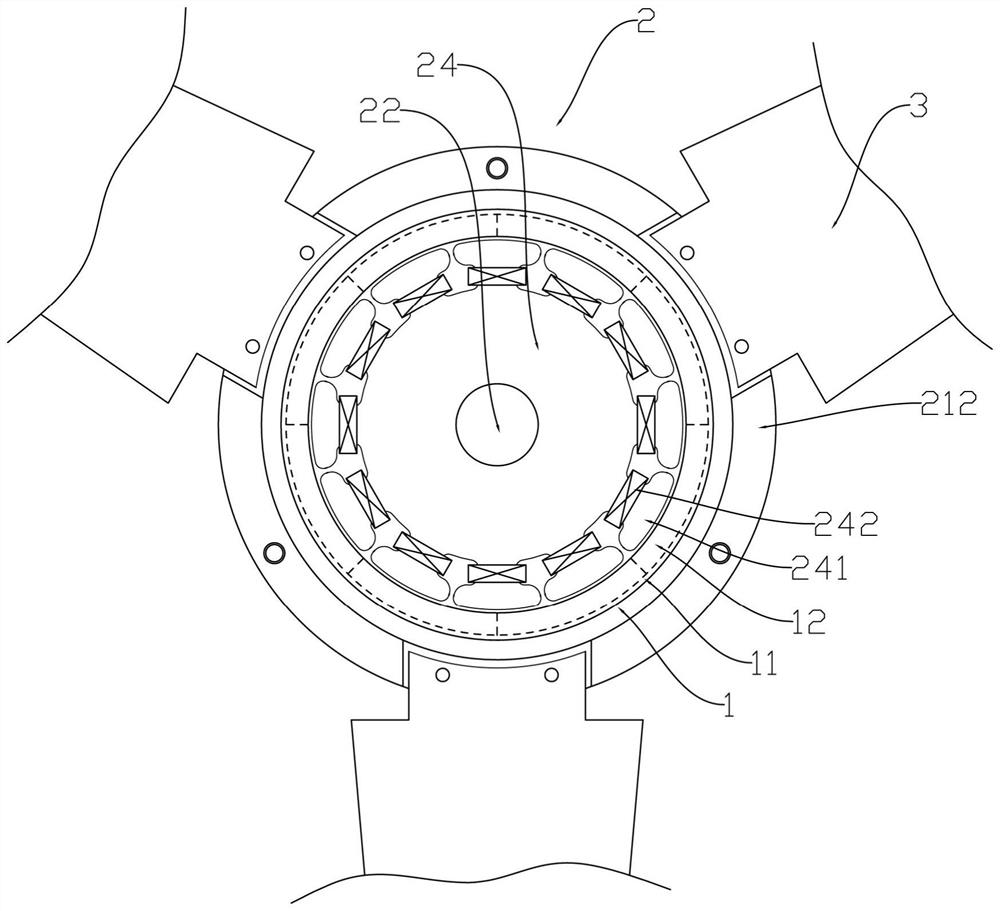

[0043] Such as figure 1 As shown, it is a permanent magnet ring 1 used in the DC outer rotor motor 2 in the embodiment of the present invention. The permanent magnet ring 1 is a circular columnar structure integrally formed by magnetic powder and adhesive. The permanent magnet ring 1 includes the same The magnetically permeable ring layer 11 on the outer side of the shaft, and the magnetic pole ring layer 12 on the coaxial inner ring side. The magnetic pole ring layer 12 is evenly provided with eight magnetic poles along the circumferential direction, and one of the adjacent magnetic poles is an N pole facing the axis, and the other is an S pole facing the axis. figure 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com