Cable quick connection structure

A cable and quick connection technology, applied in the direction of cable joints, etc., can solve the problems of inability to protect the line insulation short circuit fault, the silicone sleeve has no sealing and insulation function, and the conductive parts are easy to oxidize and corrode, so as to achieve simple and reliable product structure, low cost, and convenience The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

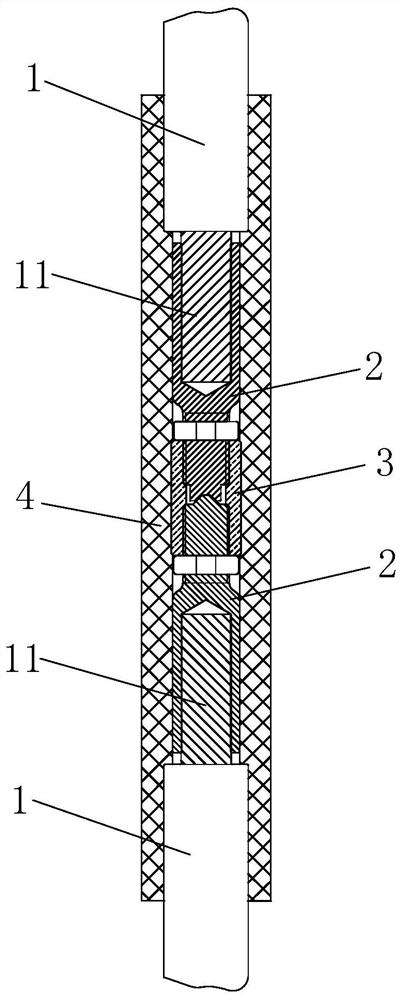

[0023] figure 1 As shown, a quick-connection structure of a cable includes a high-voltage cable 1 , a copper lug 2 , a conductive member 3 and a cable accessory 4 . The conductive member 3 is provided with an axial through hole, and the two ends of the through hole are respectively a first connection port 31 and a second connection port 32. The inner wall of the first connection port 31 is provided with a left-hand screw hole, and the inner wall of the second connection port 32 is provided with Right-hand threaded holes. The high-voltage cable core 11 and the cable copper nose 2 are fastened and connected by crimping process. The two cable copper noses 2 are respectively provided with threads that match the first connection port 31 and the second connection port 32, and the cable copper nose 2 is screwed into the The conductive part 3 is finally locked by a nut. The joints of the two copper lugs 2 are respectively provided with a convex surface and a concave surface which ca...

Embodiment 2

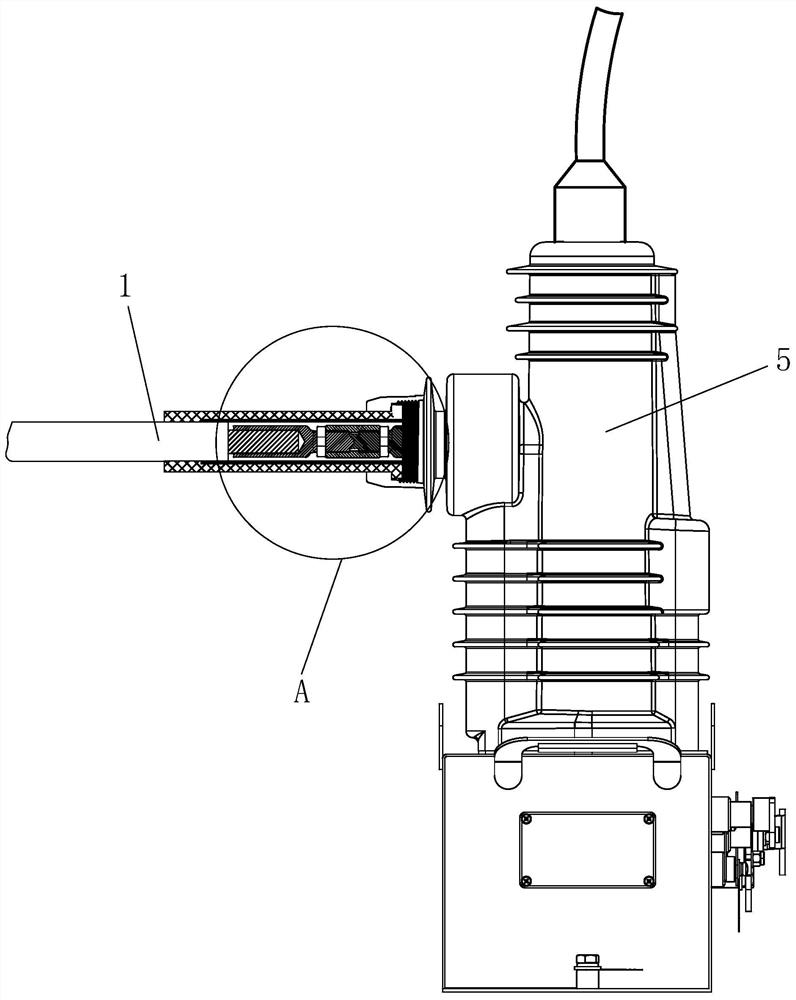

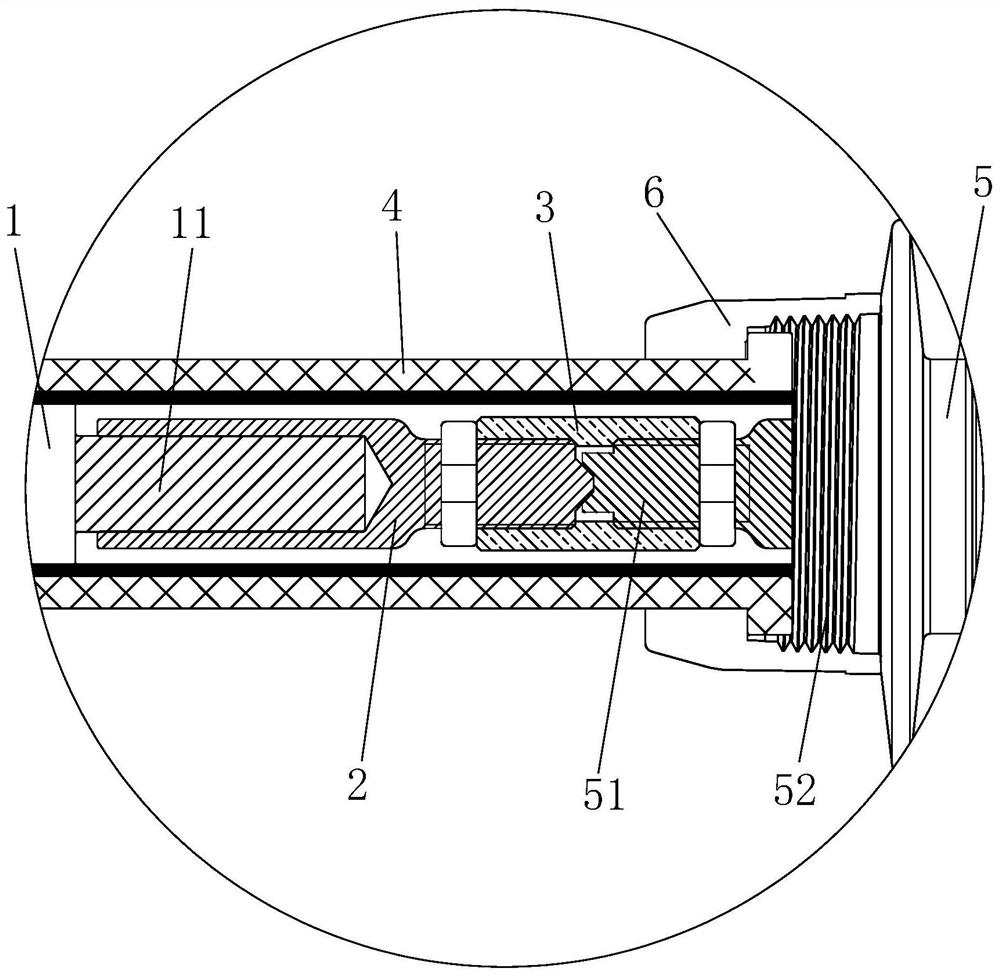

[0026] figure 2 and image 3 As shown, a quick-connecting cable structure includes a high-voltage cable 1 , a cable copper lug 2 , a switch pole 5 , a conductive member 3 and a cable accessory 4 . The conductive member 3 is provided with an axial through hole, and the two ends of the through hole are respectively a first connection port 31 and a second connection port 32. The inner wall of the first connection port 31 is provided with a left-hand screw hole, and the inner wall of the second connection port 32 is provided with Right-hand threaded holes. The high-voltage cable core 11 and the cable copper lug 2 are tightly connected by crimping process. The cable copper lug 2 is provided with a screw thread matching the first connection port 31. The cable copper lug 2 is screwed into the conductive part 3 and then locked by a nut . The outlet stud 51 of the switch pole 5 is provided with a screw thread matched with the second connection port 32 , and the outlet stud 51 is sc...

Embodiment 3

[0029] Figure 4 and Figure 5 As shown, a cable quick connection structure includes a switch pole 5 , an isolation pole 7 , a conductive member 3 and a cable accessory 4 . The conductive member 3 is provided with an axial through hole, and the two ends of the through hole are respectively a first connection port 31 and a second connection port 32, the inner wall of the first connection port 31 is provided with a left-hand screw hole, and the inner wall of the second connection port 32 is provided with Right-hand threaded holes. The outlet stud 5 of the switch pole 5 is provided with a thread matching the first connection port 31 , and the outlet stud 71 of the isolation pole 7 is provided with a thread matching the second connection port 32 . One end of the outlet stud 51 of the switch pole 5 is provided with a concave surface, and one end of the outlet stud 71 of the isolation pole is provided with a convex surface, and the convex surface and the concave surface cooperate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com