A side-mounted fixed tube mother hardware

A technology for fixing pipes and fittings, applied in the installation of busbars, cables, electrical components, etc., can solve problems such as breakage of pipes and fittings, and achieve the effects of stable force, safe current-carrying, and reliable current-carrying performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments. Although the present invention will be described in conjunction with preferred embodiments, it should be understood that this does not mean that the present invention is limited to the embodiments. On the contrary, the present invention will cover alternatives, improvements, and equivalents that can be included within the scope of the present invention as defined by the appended claims.

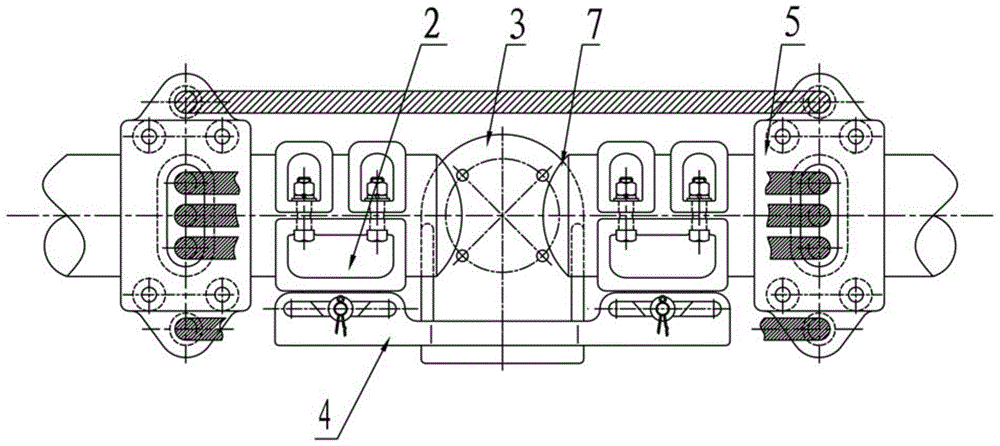

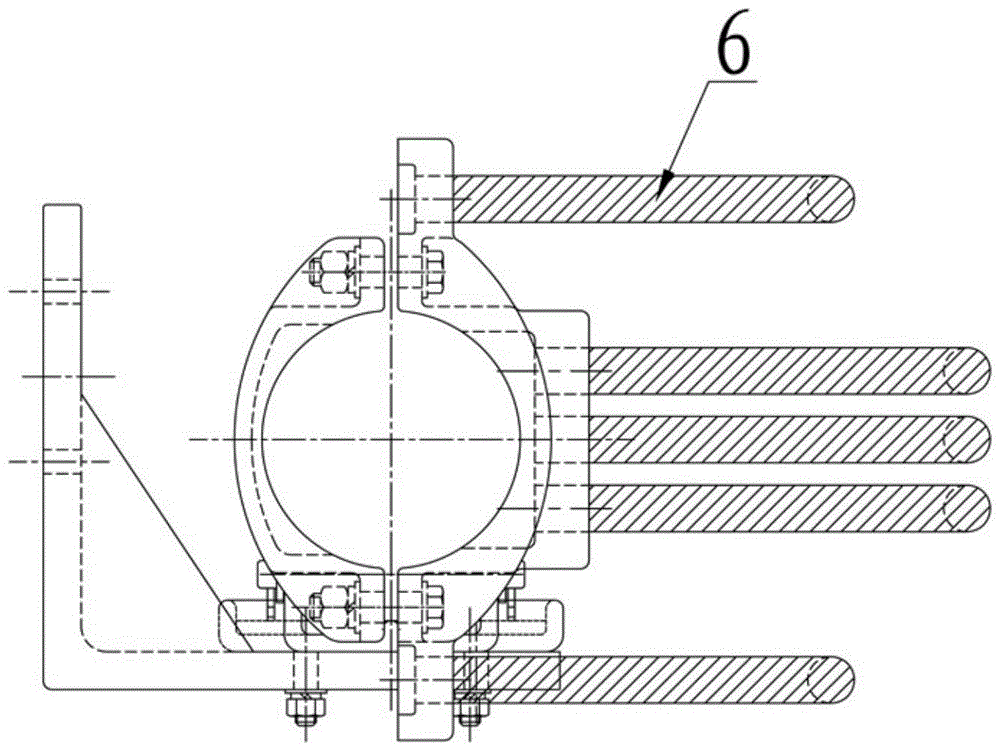

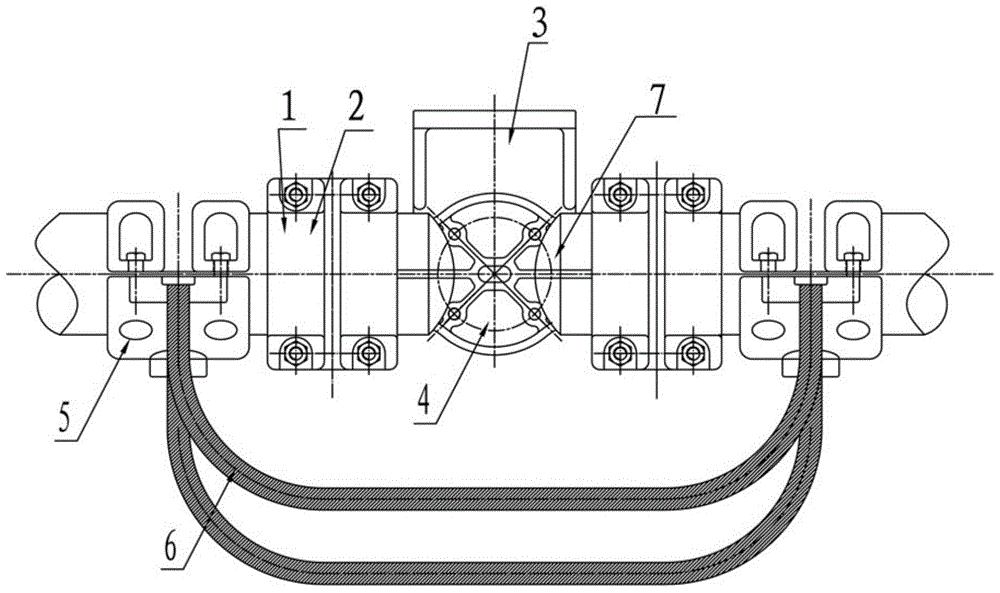

[0018] Such as Figure 1 to Figure 3 As shown, this kind of side-mounted fixed diversion pipe female fittings belongs to the supporting fittings of the two-channel Shazhou 750kV substation project. The side-mounted fixed diversion pipe female fittings are composed of a fitting line clamp cover plate 1, a fitting line clamp The main body 2, the wire clamp base 3, the supporting and fixing plate 4, the guide wire clamp body 5, the 5 guide wires 6, and the end cap 7 are composed. The har...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com