Method for calculating reactivity and post-reaction strength of alkali-rich coke in high-titanium blast furnace

A post-reaction strength and calculation method technology, applied in the field of metallurgical production technology, can solve problems such as poor practicability, difficult separation of slag and iron, and difficult real-time monitoring of metallurgical processes, etc., to achieve the effect of fast calculation and efficient judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0053] The object of the present invention is to provide a method for calculating the reactivity and post-reaction strength of the inner alkali-rich coke, which can quickly calculate the reactivity and post-reaction strength of the blast furnace alkali-rich coke based on the researched blast furnace alkali metal load data, The purpose of simply and efficiently judging the coke performance index in the blast furnace is achieved.

[0054] Technical solutions:

[0055] In order to achieve the above object, the present invention calculates the reactivity and post-reaction strength of blast furnace alkali-rich coke through the following steps:

[0056] Step 1: Define the relationship between the concentration of alkali metals in the target blast furnace and the properties of coke

[0057] Take the original coke sample of the target blast furnace, prepare alkali-rich coke by high-temperature gas phase adsorption method, and then conduct coke reactivity and post-reaction strength te...

Embodiment 1

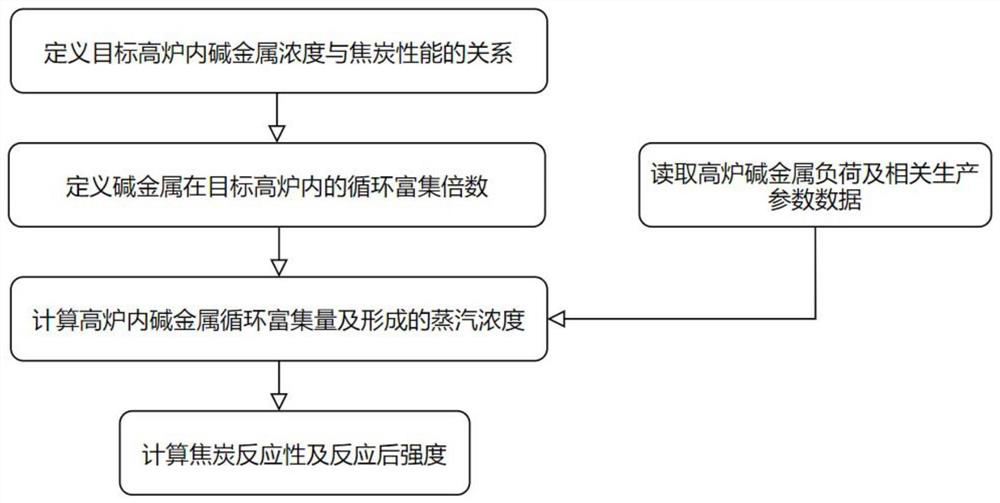

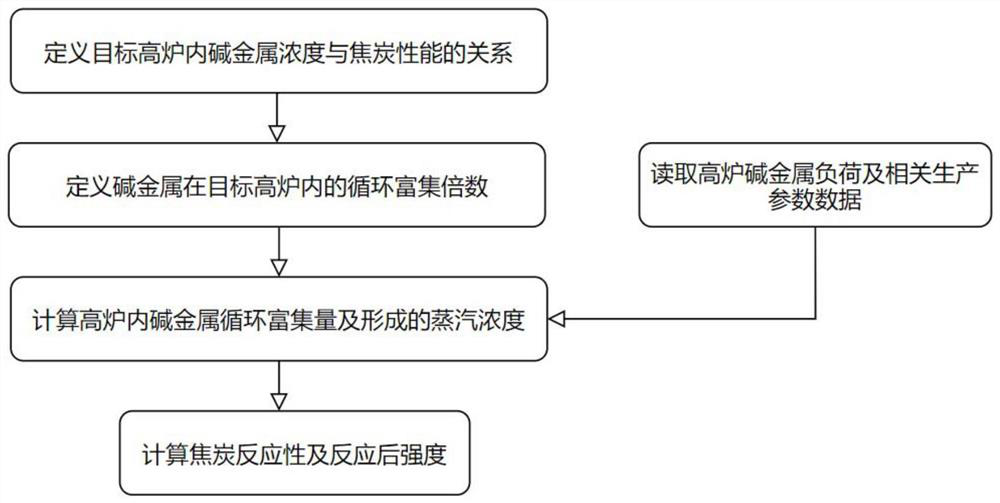

[0087] In order to make the above-mentioned features and advantages of the present invention more obvious and understandable, in conjunction with the attached figure 1 Decision logic diagram, taking the actual production data of a certain iron and steel company's blast furnace as an example, the present invention is described in further detail:

[0088] figure 1 It is the decision logic diagram of the invention.

[0089] Step 1: Define the relationship between the concentration of alkali metals in the target blast furnace and the properties of coke

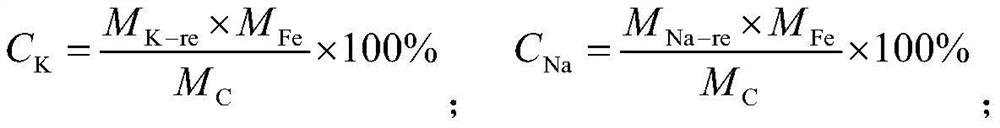

[0090] Take the original coke sample of the target blast furnace, prepare alkali-rich coke by high-temperature gas phase adsorption method, and then conduct coke reactivity and post-reaction strength test according to the national standard GB / T4000-2017, record the data of each experiment, including the preparation of alkali-rich coke experiment Medium alkali metal concentration (potassium vapor concentration C K and sodium vap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com