Key geometric error tracing method for multi-axis numerical control machine tool

A numerical control machine tool and geometric error technology, applied in program control, computer control, comprehensive factory control, etc., can solve problems such as large amount of calculation and complicated calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

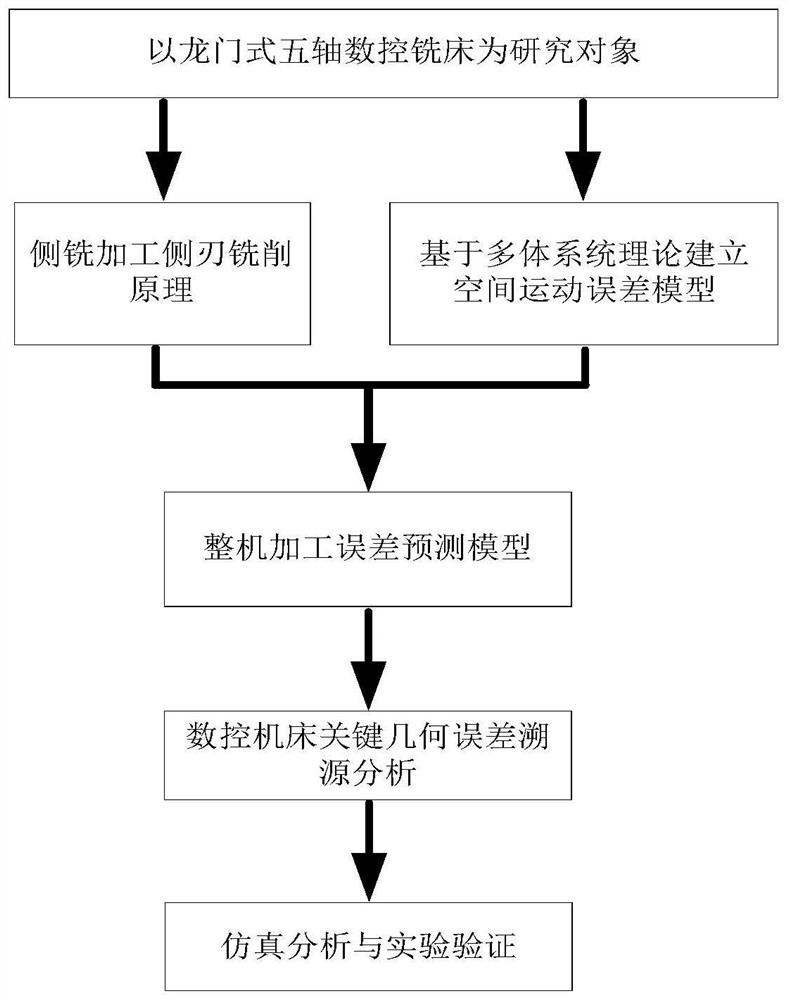

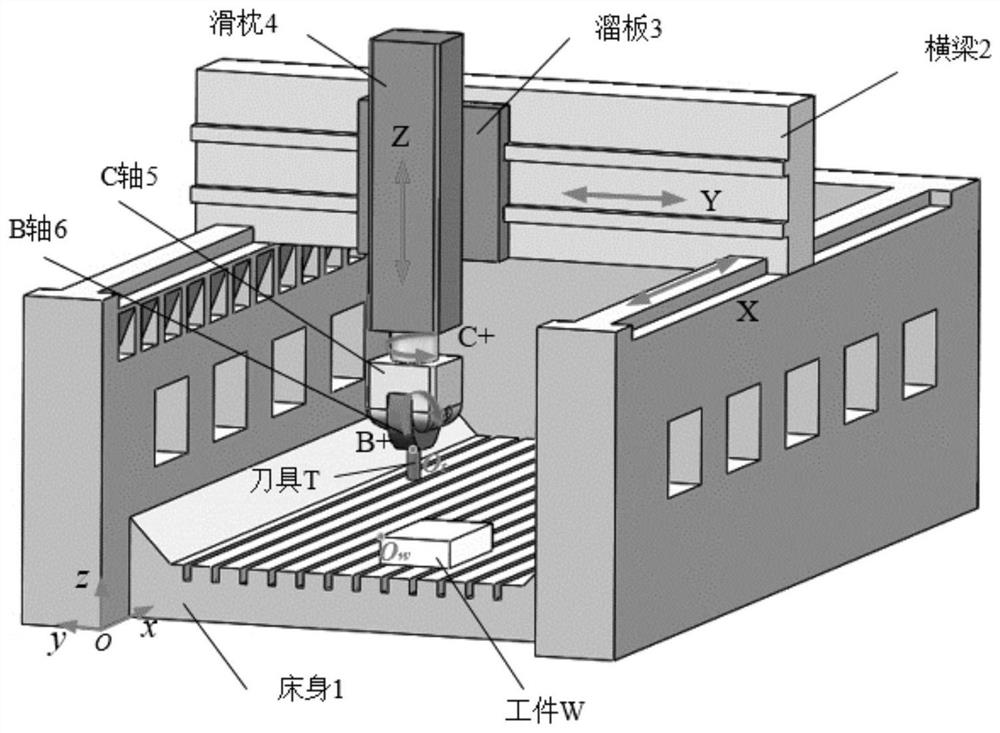

[0124] The present invention takes a five-axis elevated beam mobile gantry CNC milling machine as an example to verify the above-mentioned five-axis CNC milling machine machining accuracy prediction method.

[0125] Specifically include the following steps:

[0126] Step 1: Take the five-axis CNC machine tool as an example to establish the spatial error model of the machine tool;

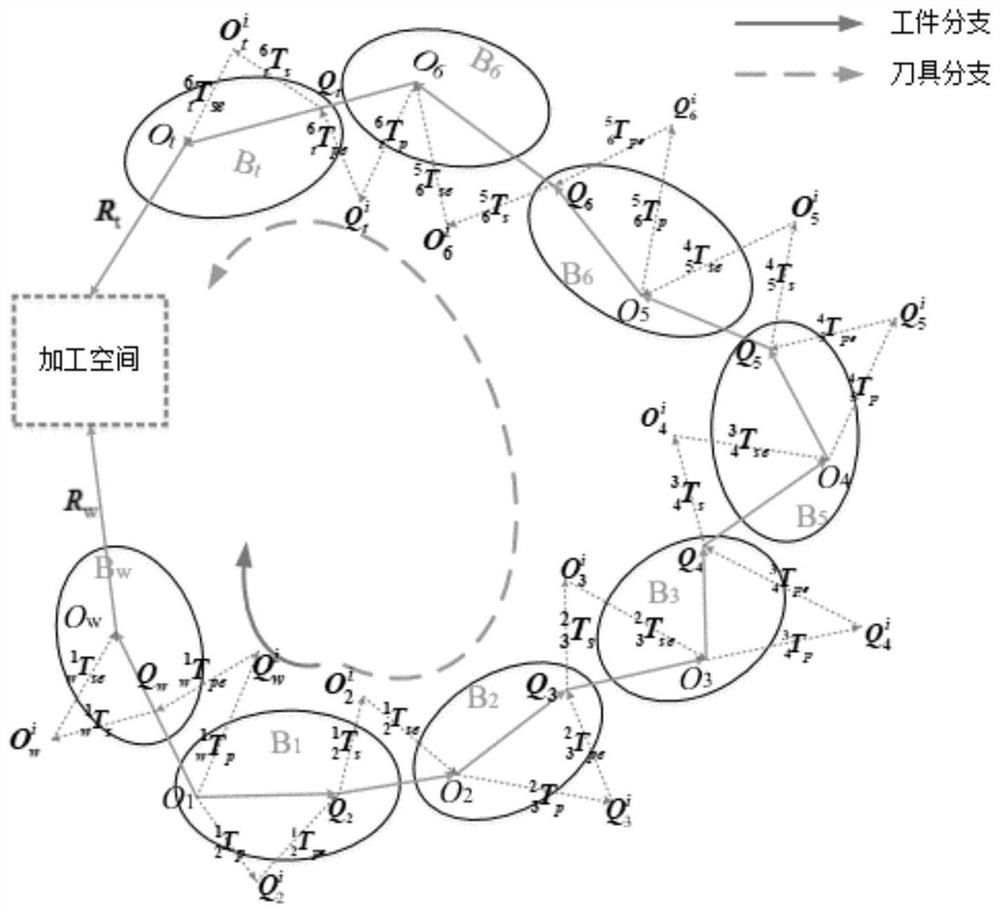

[0127] Based on the theory of multi-body system kinematics, the structure of the machine tool and the relationship between each body are described by topological structure graph and low-order body array table, the geometric error of the CNC machine tool is analyzed, the generalized coordinate system is established, and the relationship between adjacent bodies is used. The feature matrix expresses the positional relationship, and the homogeneous transformation matrix is used to express the relationship between multi-body systems;

[0128] Step 1.1 establishes the topology of the five-axis CNC mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com