Optical camera lens

A camera lens, optical technology, applied in optics, optical components, instruments, etc., can solve the problems of large image surface, large aperture and miniaturization at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

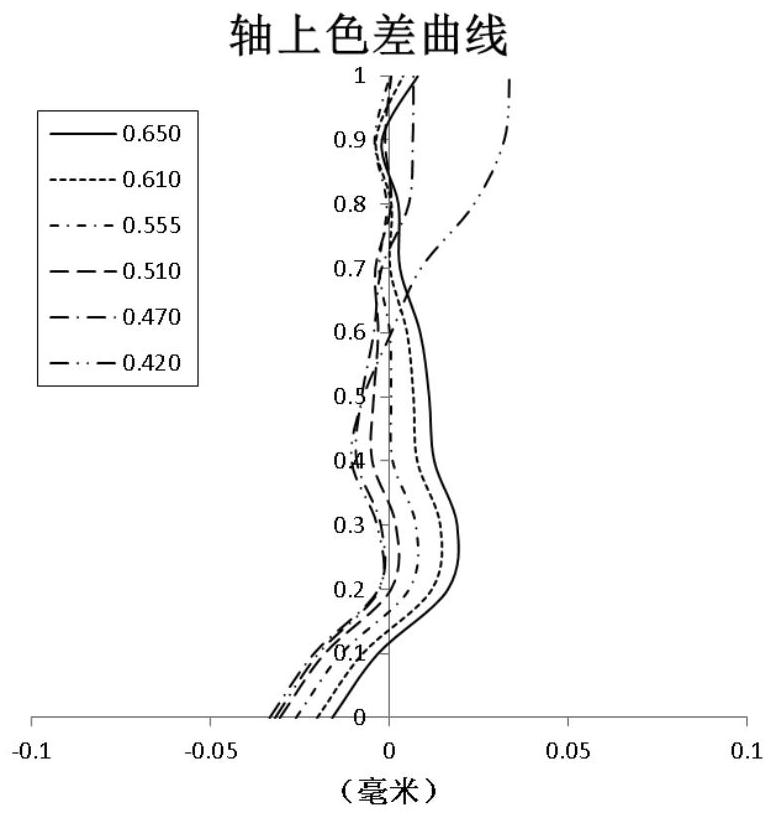

[0067] Such as Figure 1 to Figure 24 As shown, the optical camera lens includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens and an eighth lens in order from the light incident side to the light output side along the optical axis The surface close to the exit side of the second lens is concave; the surface close to the incident side of the fifth lens is convex; wherein, there are at least three from the surface close to the incident side of the first lens to the surface close to the exit side of the fourth lens The surface is concave; the effective focal length f of the optical camera lens and the entrance pupil diameter EPD of the optical camera lens meet: f / EPD<1.3.

[0068] By restricting the ratio between the effective focal length f of the optical camera lens and the entrance pupil diameter EPD of the optical camera lens within a reasonable range, on the basis of ensuring a large image surface, the deflection angle ...

Embodiment 2

[0088] Such as Figure 1 to Figure 24 As shown, the optical camera lens includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens, a seventh lens and an eighth lens in order from the light incident side to the light output side along the optical axis The surface close to the exit side of the second lens is concave; the surface close to the incident side of the fifth lens is convex; wherein, there are at least three from the surface close to the incident side of the first lens to the surface close to the exit side of the fourth lens The surface is concave; the maximum value Namax of the refractive index in the first lens to the fourth lens and the second maximum value Nbmax of the refractive index in the fifth lens to the eighth lens satisfy: (Namax+Nbmax) / 2>1.6 .

[0089] Preferably, 1.6<(Namax+Nbmax) / 2<1.7.

[0090] The optical camera lens of the present application reduces the deflection angle of the incident light on the basis of ensuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com