Transparent potassium sodium niobate crystal and preparation method and application thereof

A technology of potassium sodium niobate and crystals, which is applied in the field of piezoelectric crystal materials, can solve the problems of low transparency of potassium sodium niobate crystals, failure to meet the needs of photovoltaic piezoelectric device applications, poor crystal quality, etc., and achieve good crystallinity , The growth process is controllable and the effect is good in repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

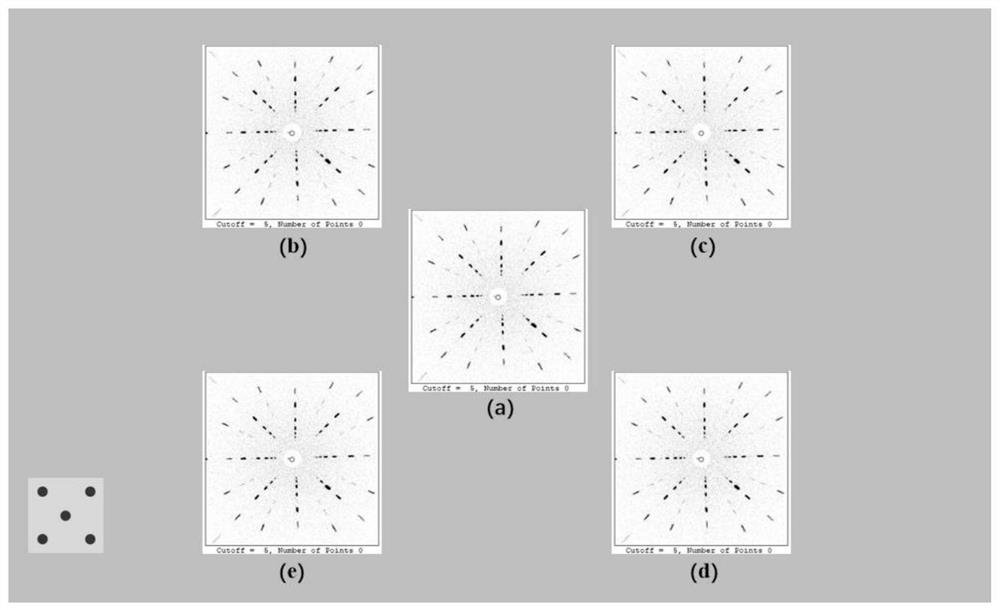

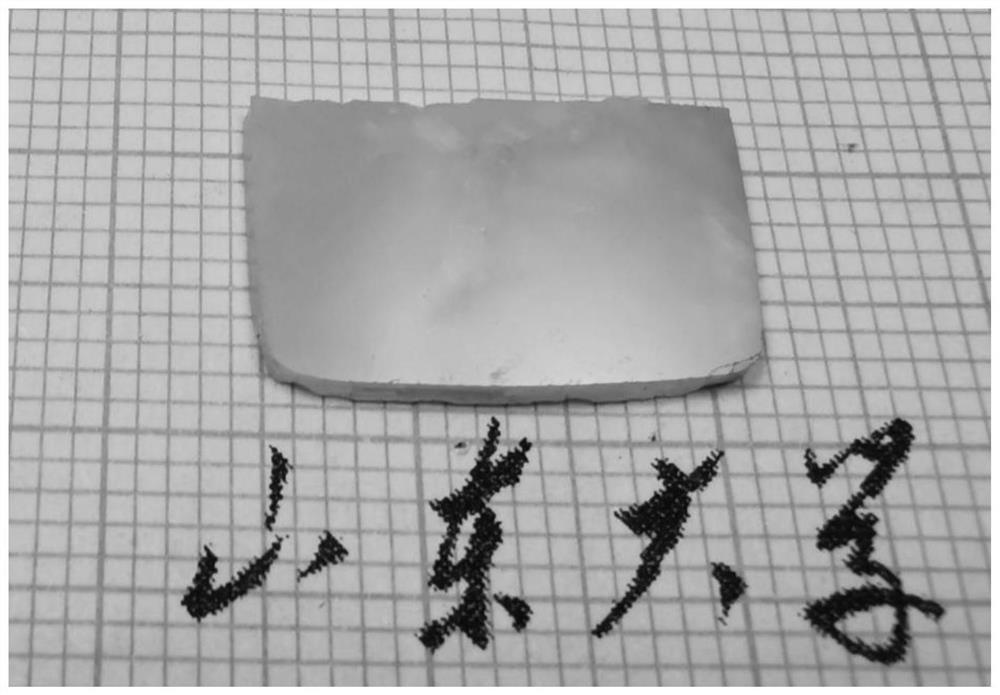

Image

Examples

Embodiment 1

[0039] Example 1: K 0.5 Na 0.5 NbO 3 crystal growth

[0040] Na with a purity of 99.99% 2 CO 3 、K 2 CO 3 and Nb 2 o 5 The raw materials were weighed according to the stoichiometric ratio and then placed in vacuum drying at 120°C, and the polycrystalline potassium sodium niobate was synthesized by a solid-state sintering method. Add the obtained polycrystalline material into the platinum crucible, and vacuumize to 1×10 -4 Pa, filled with 20% O by volume 2The mixed gas of +80% Ar is brought to an atmospheric pressure, the temperature is raised to slowly melt the raw materials, and the temperature is kept constant for 2 hours after all the raw materials are melted. After adjusting the seeding temperature, the potassium sodium niobate seed crystal is slowly lowered to the surface of the melt for shoulder and equal-diameter growth. The crystals are stripped as they grow to the desired size. During the process, the crystal pulling speed was 1 mm / h, and after the growth w...

Embodiment 2

[0041] Embodiment 2: (Na 0.5 K 0.5 )(Nb 0.98 mn 0.02 )O 3 crystal growth

[0042] Na with a purity of 99.99% 2 CO 3 、K 2 CO 3 , Nb 2 o 5 and MnO raw materials were weighed according to the stoichiometric ratio, and then placed in vacuum drying at 150 ° C, and the polycrystalline potassium sodium niobate was synthesized by a solid-state sintering method. Add the obtained polycrystalline material into the platinum crucible, and vacuumize to 1×10 -4 Pa, filled with 20% O by volume 2 The mixed gas of +80% Ar is brought to an atmospheric pressure, the temperature is raised to slowly melt the raw materials, and the temperature is kept constant for 2 hours after all the raw materials are melted. After adjusting the planting temperature, planting, shouldering and equal-diameter growth are carried out at one time. The crystals are stripped as they grow to the desired size. During the process, the crystal pulling speed was 1 mm / h, and after the growth was completed, it was...

Embodiment 3

[0043] Embodiment 3: (Na 0.5 K 0.5 )(Nb 0.95 Ta 0.05 )O 3 crystal growth

[0044] Na with a purity of 99.99% 2 CO 3 、K 2 CO 3 , Nb 2 o 5 and Ta 2 o 5 The raw materials were weighed according to the stoichiometric ratio and placed in vacuum drying at 170°C, and the potassium sodium niobate polycrystalline material was synthesized by a solid-state sintering method. Add the obtained polycrystalline material into the platinum crucible, and vacuumize to 1×10 -4 Pa, filled with 20% O by volume 2 The mixed gas of +80% Ar is brought to an atmospheric pressure, the temperature is raised to slowly melt the raw materials, and the temperature is kept constant for 2 hours after all the raw materials are melted. After adjusting the planting temperature, planting, shouldering and equal-diameter growth are carried out at one time. The crystals are stripped as they grow to the desired size. During the process, the crystal pulling speed was 1 mm / h, and after the growth was compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com