Process for removing dioxin in fly ash

A fly ash and process technology, applied in gas treatment, calcium carbonate/strontium/barium, electrolysis process, etc., can solve the problems of high infrastructure construction cost, high temperature requirements of incineration process, unfavorable energy saving and emission reduction, etc., and meet the reaction conditions Easy to meet, reduce operating costs, and easy to build

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

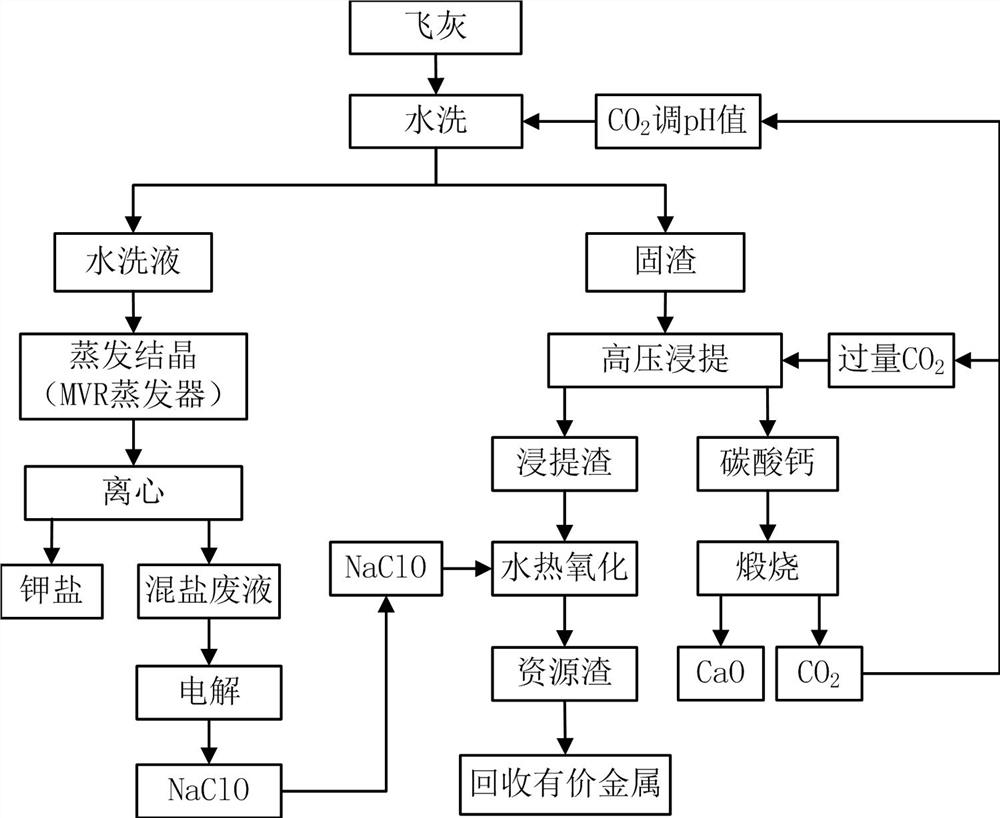

[0024] Example 1, such as figure 1 As shown, it includes the following steps:

[0025] Step 1, washing the fly ash with water, mixing the fly ash and water to prepare a slurry, and then using a suction filter to filter the prepared slurry to obtain a washing solution and solid residue;

[0026] Step 2, carbon dioxide high-pressure leaching, washing the solid slag with water to prepare a slurry, and placing the prepared slurry in a high-pressure container, while passing an excessive amount of carbon dioxide into the slurry, and using carbon dioxide high-pressure leaching to extract the The calcium contained in the solid slag is converted into calcium bicarbonate and dissolved in water, and the slurry that has been leached by carbon dioxide under high pressure is suction-filtered with a suction filter to obtain the leaching residue and filtrate. Decompose to generate calcium carbonate; and, the calcium carbonate can be calcined to obtain quicklime and carbon dioxide gas, the qu...

Embodiment 2

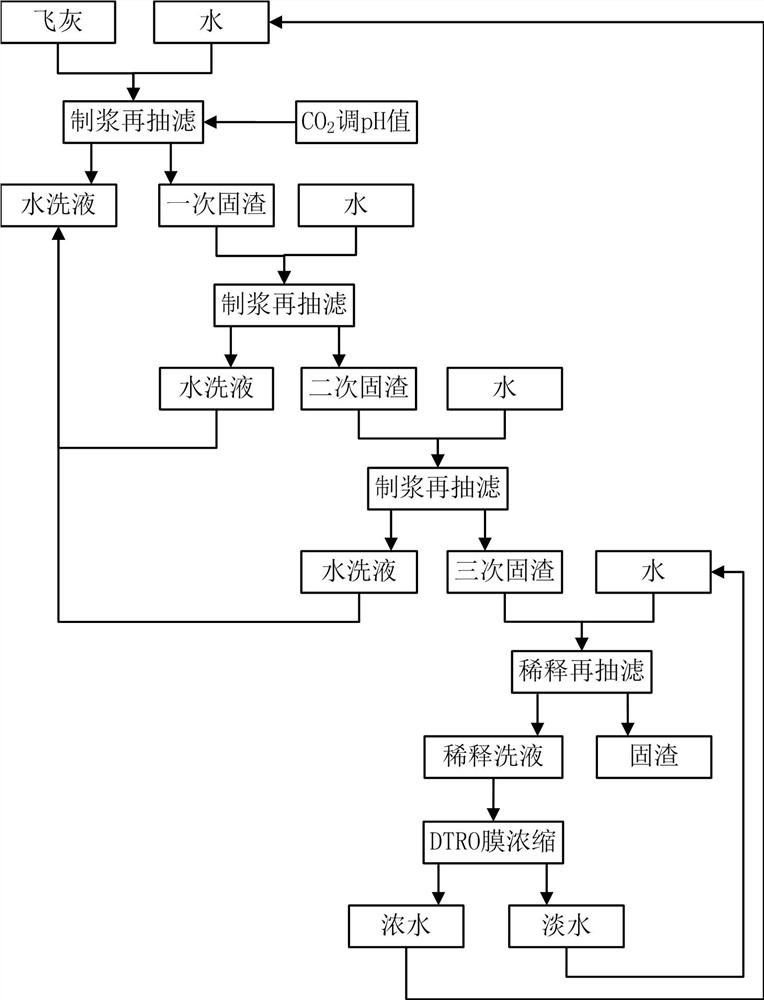

[0030] Example 2, such as figure 1 , 2 As shown, it includes the following steps:

[0031] Step 1. Washing of fly ash by using multi-stage reverse pulping fly ash washing method,

[0032] 1) Mix fly ash and water according to the solid-to-liquid ratio of 1:3-5 to prepare slurry, and at the same time, pass carbon dioxide gas into the slurry to adjust the pH value to 6-8, which is conducive to the precipitation of heavy metals and calcium ions;

[0033] 2) Suction filter the slurry prepared in 1) with a suction filter to obtain washing liquid and primary solid residue;

[0034] 3) Mix the primary solid slag obtained in 2) with water at a solid-to-liquid ratio of 1:3-5 to prepare a slurry;

[0035] 4) Suction filter the slurry prepared in 3) with a suction filter to obtain washing liquid and secondary solid residue;

[0036]5) Mix the secondary solid slag obtained in 4) with water at a solid-to-liquid ratio of 1:3-5 to prepare a slurry;

[0037] 6) Suction filter the slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com