Waste leather crushing and recycling equipment

A technology for recycling equipment and leather, applied in presses, grain processing, manufacturing tools, etc., can solve problems such as insufficient crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

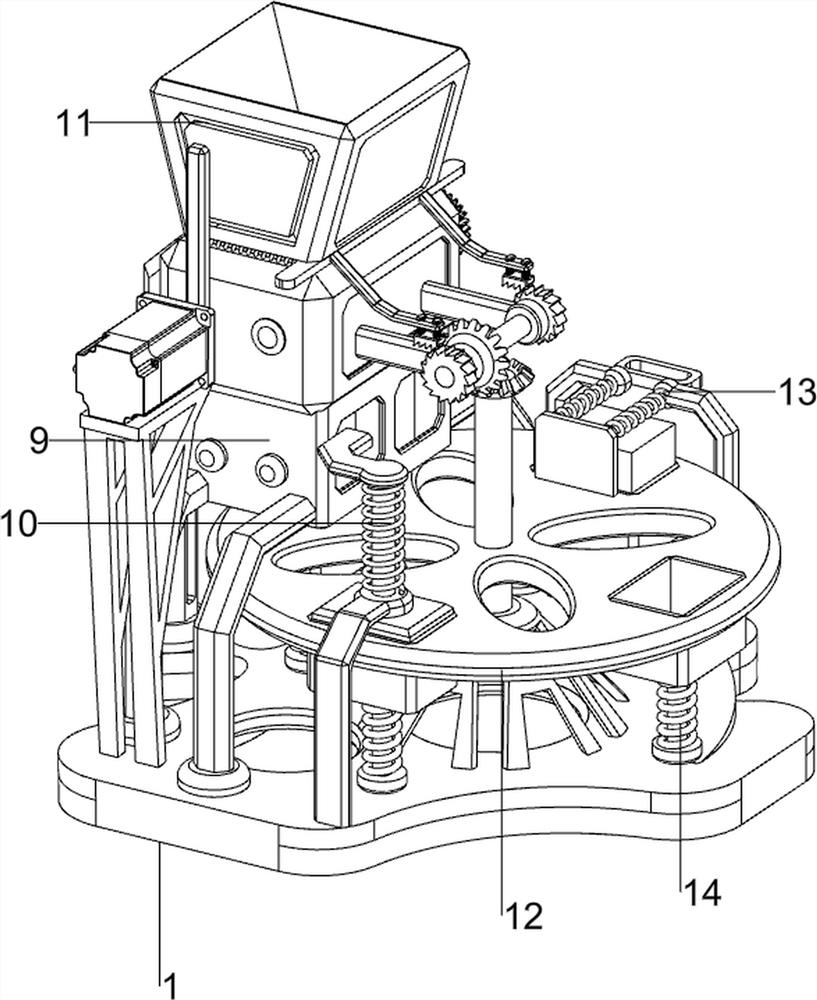

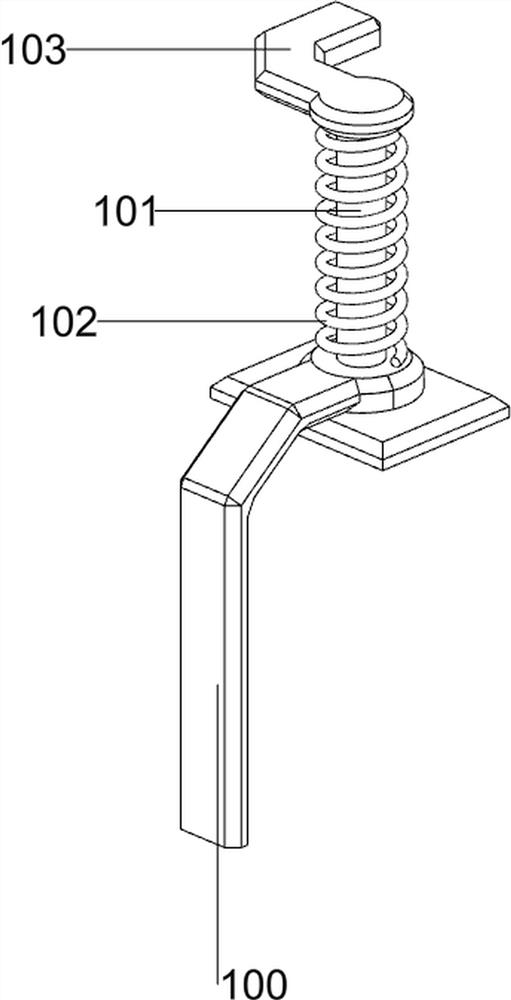

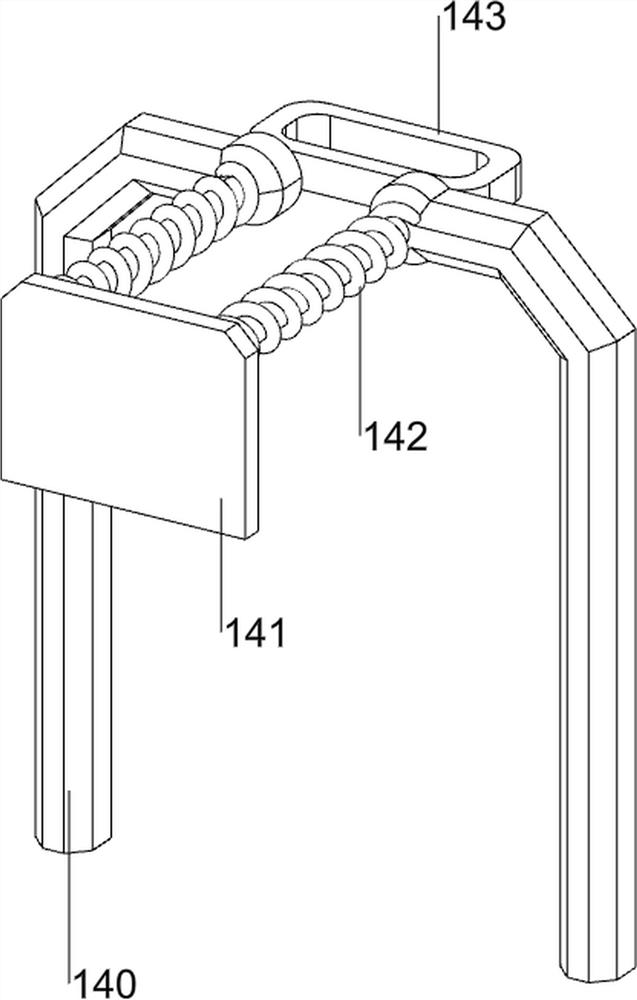

[0027] A kind of crushing and recycling equipment for waste leather, such as Figure 1-4 As shown, it includes a bottom plate 1, a slideway 2, a servo motor 3, a pressing rod 4, a first protective shell 5, a guide rod 6, a rolling wheel 7, a first gear 8, a secondary crushing mechanism 9 and a pressing mechanism 10 , the right rear side of the base plate 1 is provided with a slideway 2, the left front side of the base plate 1 is provided with a servo motor 3, the output shaft of the servo motor 3 is connected to a pressure rod 4, and the left side of the base plate 1 is provided with a first protective shell 5 in the middle, the first protective shell 5 is connected with two rolling wheels 7 in a rotating manner, and the output shaft of the servo motor 3 is connected to the left rolling wheel 7. Guide rods 6 are evenly arranged on the left and right sides of the inner upper part of the first protective shell 5, and the rear of the rolling wheels 7 Both sides are provided with ...

Embodiment 2

[0032] On the basis of Example 1, such as Figure 5-8 As shown, an intermittent feeding mechanism 11 is also included, and the intermittent feeding mechanism 11 includes a first material frame 110, a blocking sheet 111, a second spring 112, a push rod 113, a third spring 114 and a one-way rack 115. The top of a protective shell 5 is provided with a first material frame 110, and the lower part of the first material frame 110 is slidably connected with a blocking piece 111, and a second spring 112 is provided between the front and rear sides of the left part of the blocking piece 111 and the first material frame 110 , the front and rear sides of the right part of the blocking piece 111 are connected with push rods 113, the right side of the push rod 113 is slidably connected with a one-way rack 115, and the top of the one-way rack 115 and the push rod 113 on the same side are provided Two third springs 114 .

[0033] When people need to unload the material, they can first place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com