Track type screen cabinet transfer device

A transfer device and track-type technology, which is applied in the direction of transportation and packaging, manual conveying devices, rotary conveyors, etc., can solve the problems of no special transfer method, inability to reverse transfer, uneven production site, etc., and achieve a reliable overall structure High performance, low manufacturing cost, beautiful appearance and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

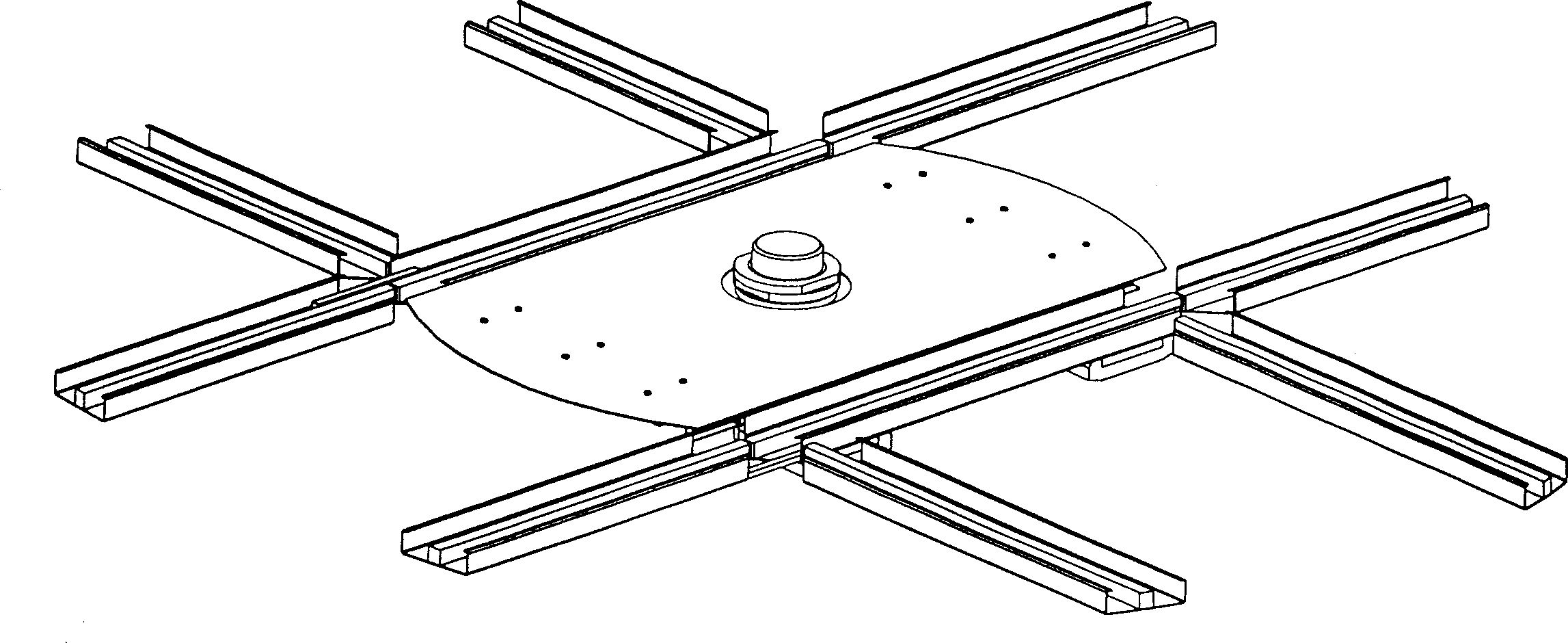

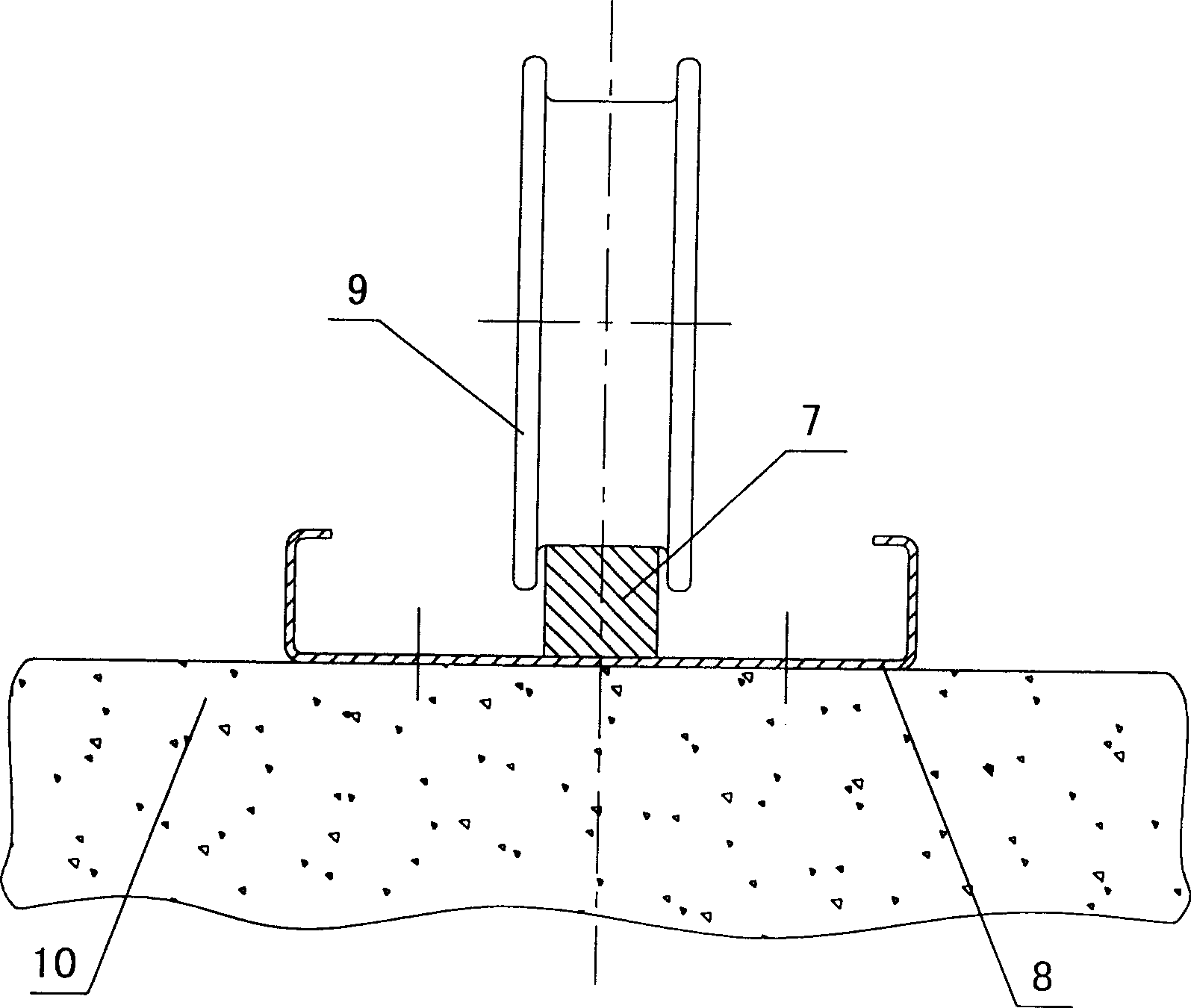

[0018] The track-type screen cabinet transfer device is composed of multiple double-tracks 1 and multiple reversing turntables 2. The reversing turntable is placed at the intersection of the tracks so that it can carry the bracket-type transfer vehicle 3 of the screen cabinet to change directions conveniently and flexibly. It is a concave groove 8, and a square steel 7 is welded in the middle of the concave groove. The square steel mainly carries the wheels 9 of the transfer vehicle to ensure that the wheels do not derail and move smoothly. Use the chain rotation mechanism to lift the screen cabinet to the bracket transfer vehicle. The reversing turntable is composed of eight parts: the central shaft assembly 11, the platform assembly 12, the turntable guide rail assembly 13, the ground guide rail 14, the bottom plate 15, the slider 16, the cover plate assembly 17 and the positioning pin 18. The track that travels on the ground, the turntable track assembly is the track that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com