Cutting knife climbing rod with unchanged climbing angle for rubber tree tapping machine

A technology of climbing rods and climbing angles, applied in the field of economic forests, can solve the problems of concentrated labor time, large labor volume, and low efficiency, and achieve the effect of uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

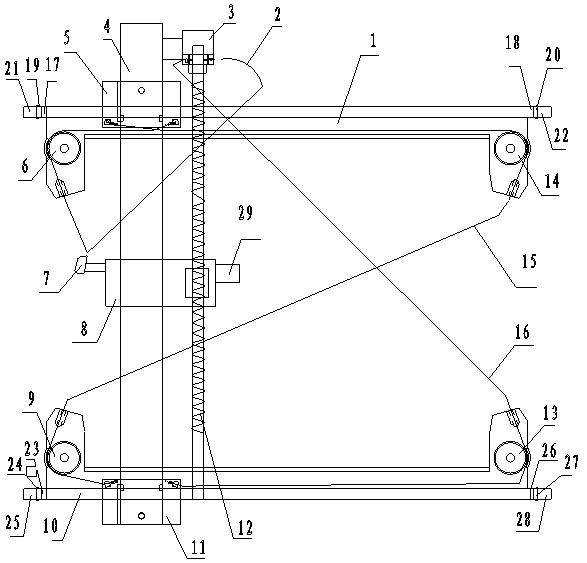

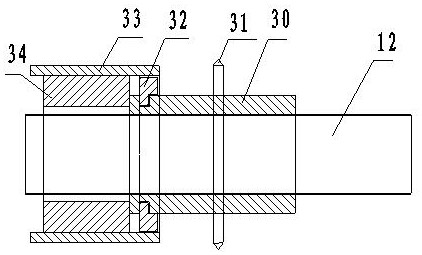

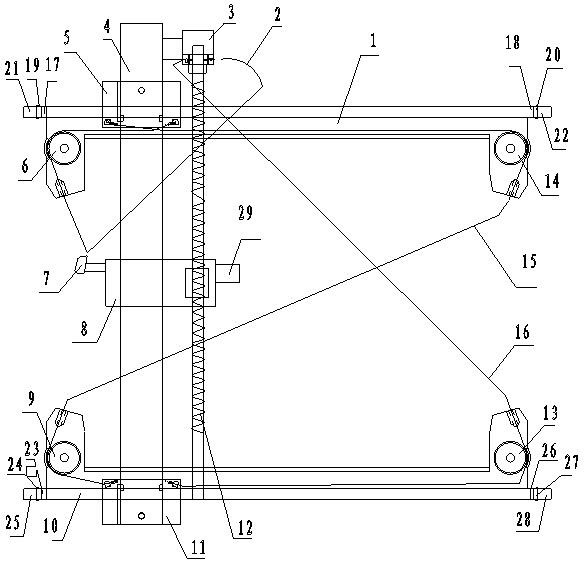

[0022] A cutting knife climbing rod used for rubber tree rubber tapping machine with constant climbing angle, including cutting knife climbing rod 12, motor I3, motor II29, knife holder 8, support pipe 4, pull wire arc-shaped guide rail I mechanism, pull wire arc-shaped The guide rail II mechanism, the pull wire circular arc guide rail I mechanism, includes the stay wire I2, the stay wire III15, the slider I5, the arc guide rail I1, the tensioning rotating wheel I6 and the tensioning wheel rotating II14, and the sliding block I5 is set in the circle On the arc-shaped guide rail I1, and reciprocatingly slide on the arc-shaped guide rail I1, wherein the tensioning rotating wheel I6 is set at one end of the arc-shaped guiding rail I1, and the tensioning rotating wheel II14 is set at the other end of the arc-shaped guiding rail I1. One end of I2 is fixed on the tooth groove, the middle is wound on the tensioning rotating wheel I6, and the other end is fixedly connected with the sli...

Embodiment 2

[0026] A cutting knife climbing rod used for rubber tree rubber tapping machine with constant climbing angle, including cutting knife climbing rod 12, motor I3, motor II29, knife holder 8, support pipe 4, pull wire arc-shaped guide rail I mechanism, pull wire arc-shaped The guide rail II mechanism, the pull wire circular arc guide rail I mechanism, includes the stay wire I2, the stay wire III15, the slider I5, the arc guide rail I1, the tensioning rotating wheel I6 and the tensioning wheel rotating II14, and the sliding block I5 is set in the circle On the arc-shaped guide rail I1, and reciprocatingly slide on the arc-shaped guide rail I1, wherein the tensioning rotating wheel I6 is set at one end of the arc-shaped guiding rail I1, and the tensioning rotating wheel II14 is set at the other end of the arc-shaped guiding rail I1. One end of I2 is fixed on the tooth groove, the middle is wound on the tensioning rotating wheel I6, and the other end is fixedly connected with the sli...

Embodiment 3

[0030]A cutting knife climbing rod used for rubber tree rubber tapping machine with constant climbing angle, including cutting knife climbing rod 12, motor I3, motor II29, knife holder 8, support pipe 4, pull wire arc-shaped guide rail I mechanism, pull wire arc-shaped The guide rail II mechanism, the pull wire circular arc guide rail I mechanism, includes the stay wire I2, the stay wire III15, the slider I5, the arc guide rail I1, the tensioning rotating wheel I6 and the tensioning wheel rotating II14, and the sliding block I5 is set in the circle On the arc-shaped guide rail I1, and reciprocatingly slide on the arc-shaped guide rail I1, wherein the tensioning rotating wheel I6 is set at one end of the arc-shaped guiding rail I1, and the tensioning rotating wheel II14 is set at the other end of the arc-shaped guiding rail I1. One end of I2 is fixed on the tooth groove, the middle is wound on the tensioning rotating wheel I6, and the other end is fixedly connected with the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com