Silicon wafer detection device and detection method

A detection device and detection method technology, which is applied in the field of optical detection, can solve problems such as affecting test accuracy, poor test accuracy, and difficulty in meeting industry needs, and achieve the effect of improving detection accuracy, meeting industry needs, and accurate distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

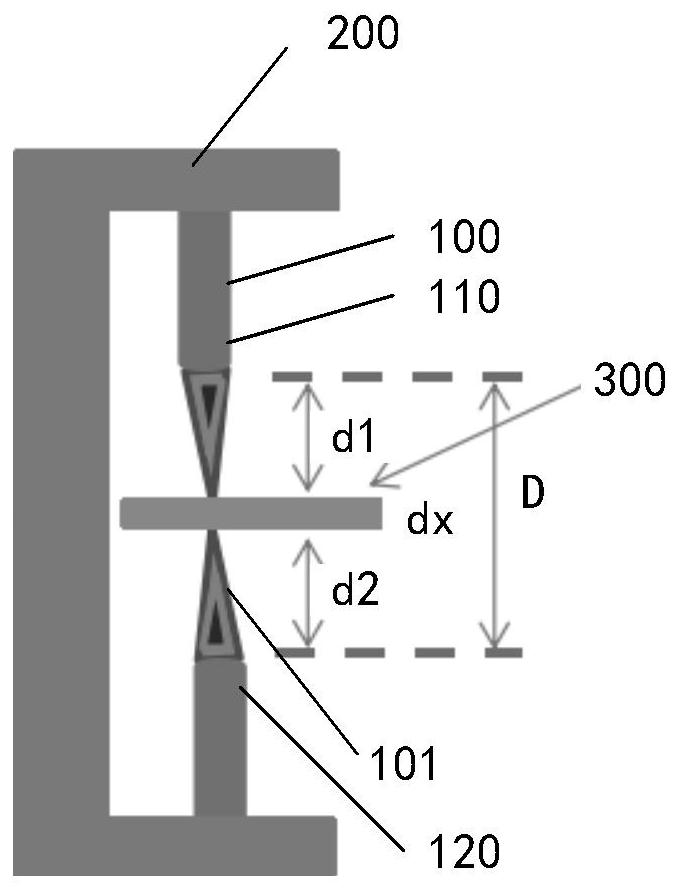

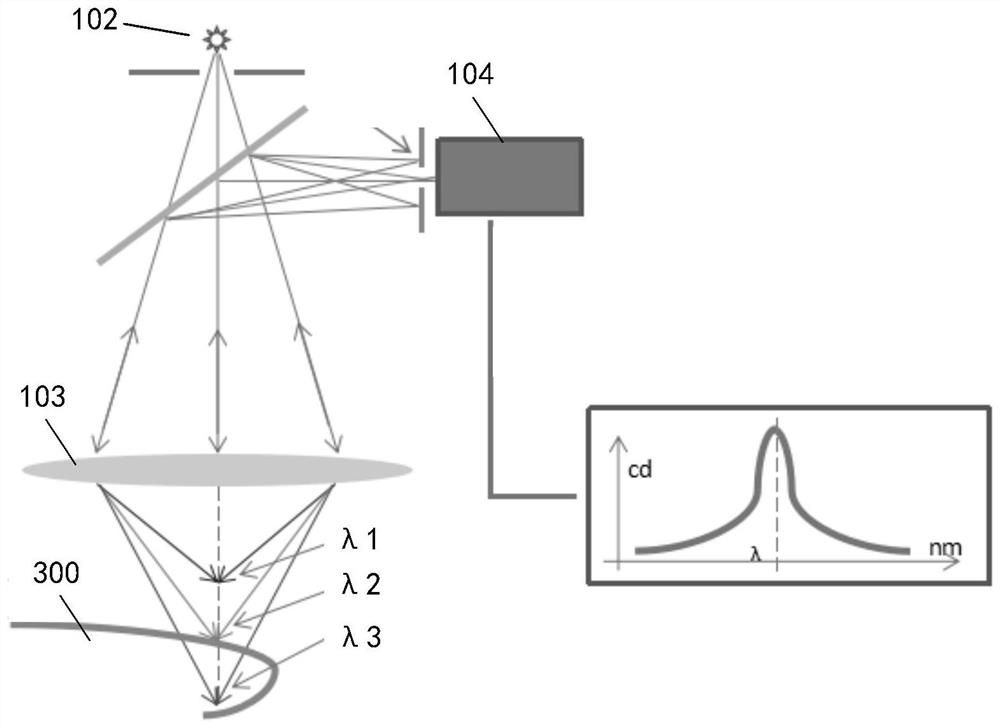

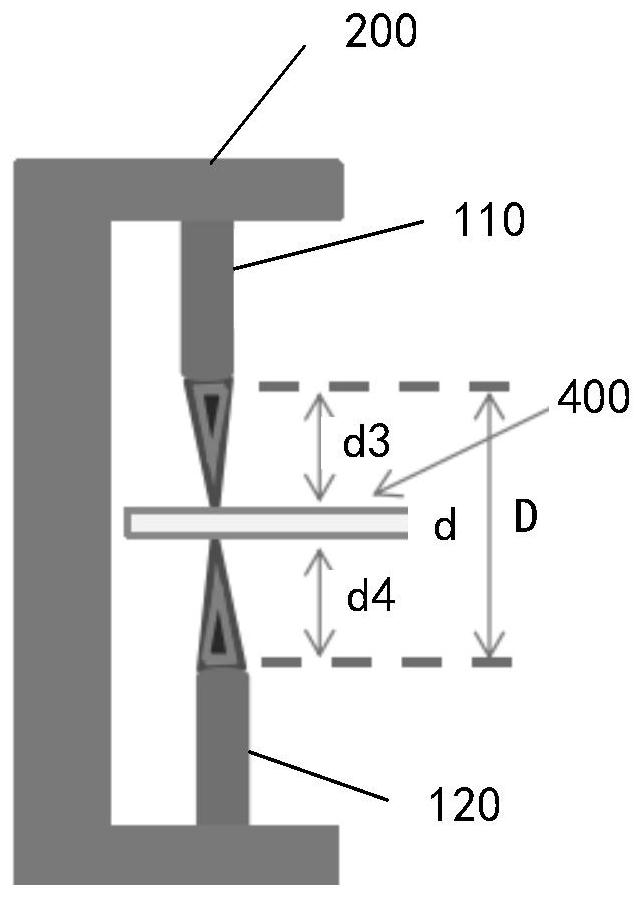

[0040] In order to better understand the technical solutions provided by the embodiments of this specification, the technical solutions of the embodiments of this specification will be described in detail below through the drawings and specific examples. The detailed description of the technical solutions of the embodiments is not a limitation to the technical solutions of this specification. In the case of no conflict, the embodiments of this specification and the technical features in the embodiments can be combined with each other.

[0041] In this document, relational terms such as first and second etc. are used only to distinguish one entity or operation from another without necessarily requiring or implying any such relationship between these entities or operations. Actual relationship or sequence. Furthermore, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article, or apparatus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com