Split mounting type heat preservation building board

A building board and assembled technology, which is applied in building thermal insulation materials, construction, thermal insulation and other directions, can solve the problems of large joint gap, inconvenient disassembly, inconvenient installation, etc., and achieves a small joint gap, easy replacement, and convenient installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

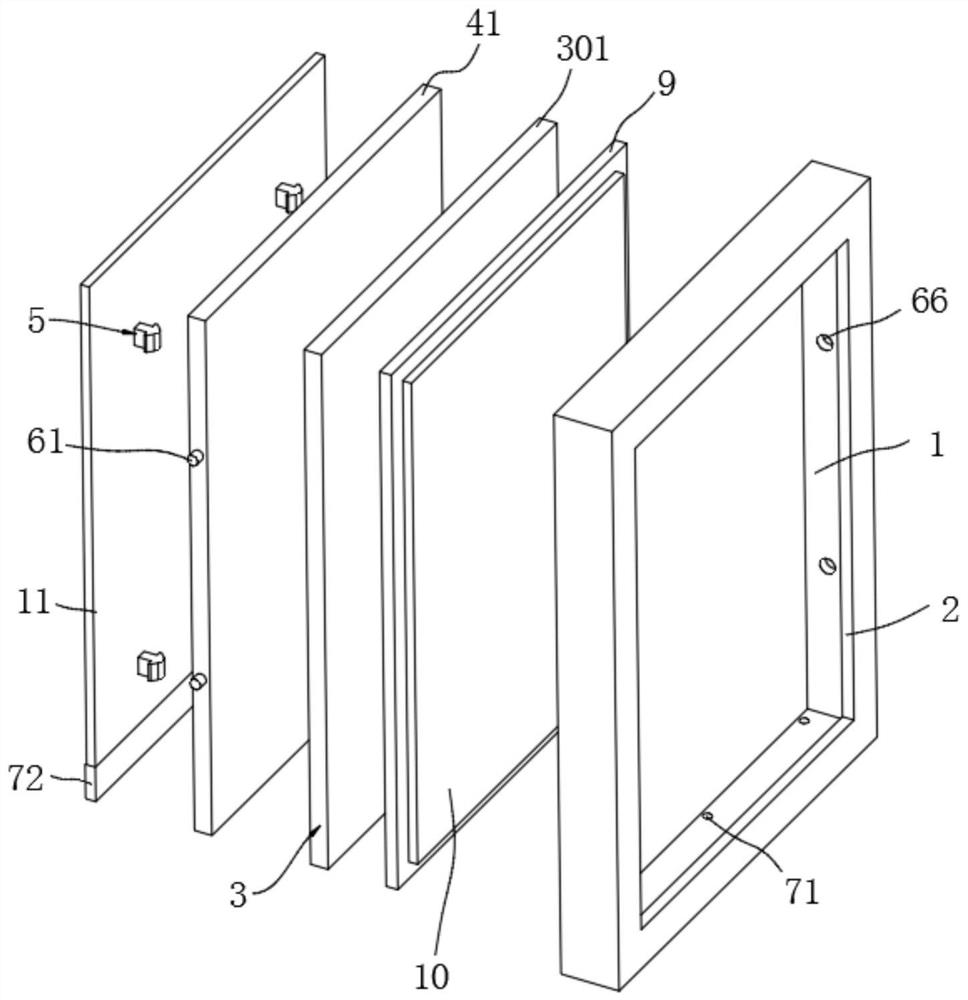

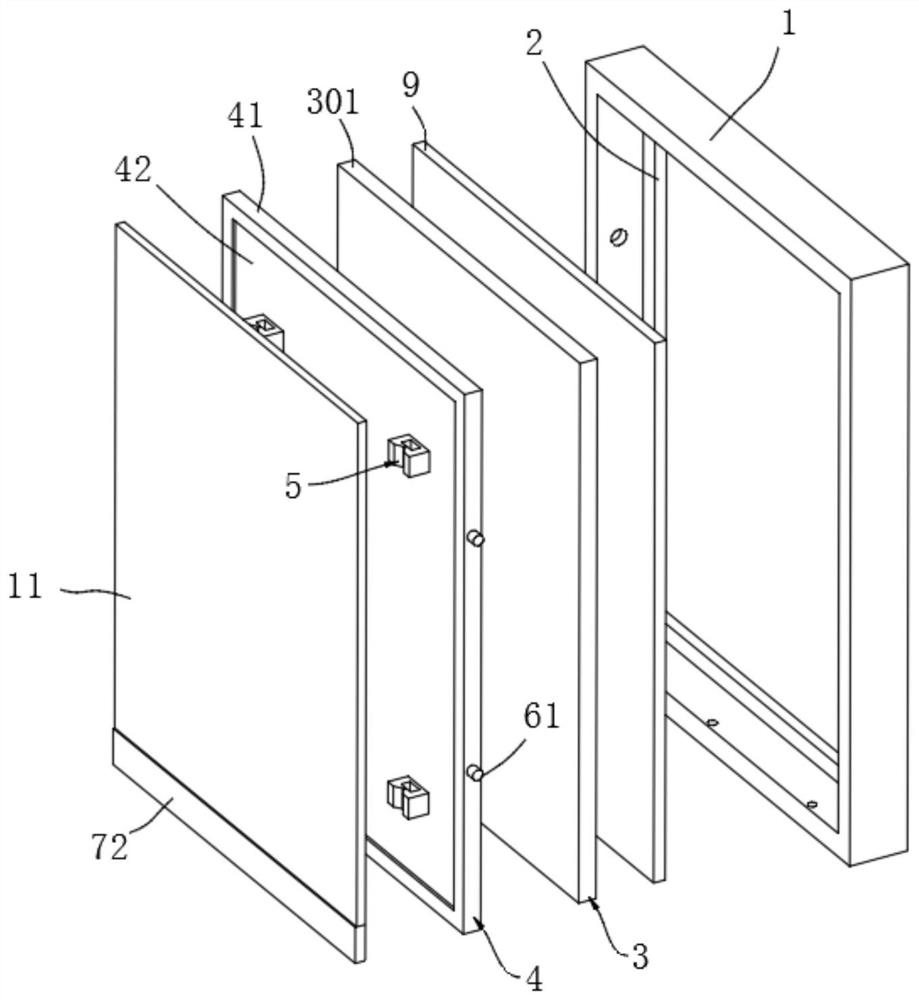

[0041]Example 1, please refer to Figure 1-3 and 7-11, this embodiment provides a technical solution: assembled thermal insulation building boards, including;

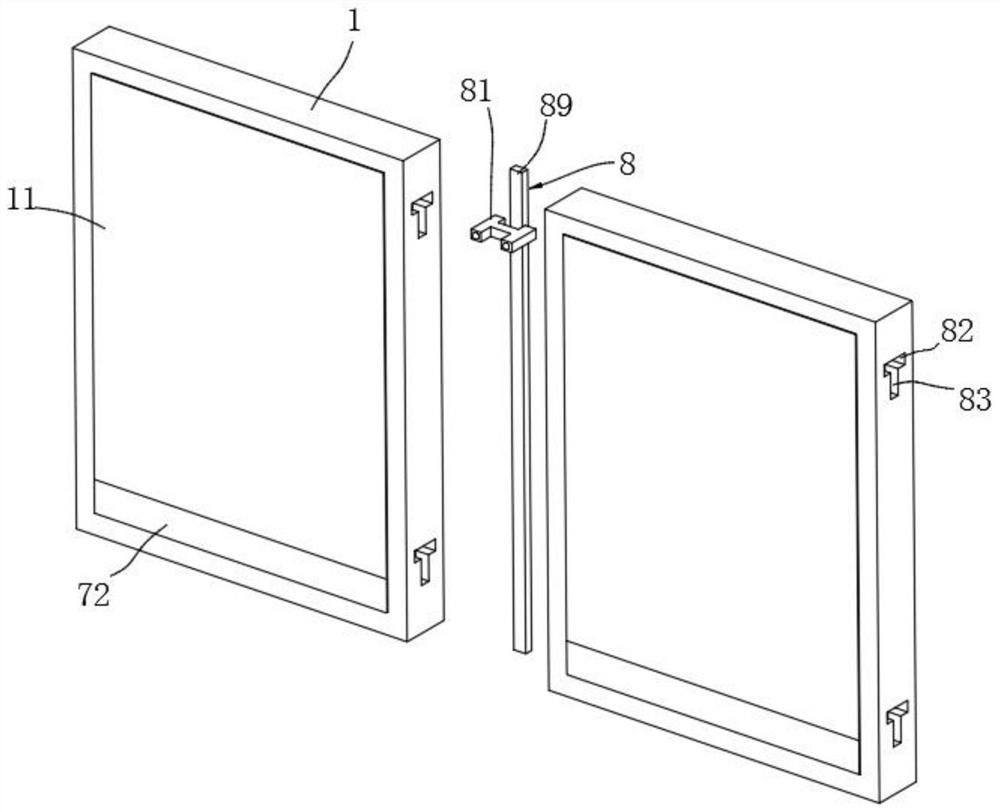

[0042] Square frame 1 has a limiting inner frame 2 inside one side, and a side of the box 1 close to the limiting inner frame 2 is provided with an encapsulation layer 9, and the side of the encapsulating layer 9 is provided with the inner side of the limiting inner frame 2. Matching embedding decoration layer 10, adjacent square frames 1 are assembled and connected together by assembling unit 8;

[0043] The assembly unit 8 includes a clamping component, a position fastening component and a seal, and the adjacent square frames 1 are connected by the clamping component, and the position fastening component for improving the stability of the clamping position is installed on the clamping component, and the corresponding A sealing member for filling gaps is provided between adjacent square frames 1 .

[0044] The frame...

Embodiment 2

[0069] Example 2, please refer to Figure 4 , this embodiment provides a technical solution: Assembled thermal insulation building panels, this embodiment is roughly the same as Embodiment 1, the difference lies in the thermal insulation layer 3;

[0070]The insulation layer 3 includes a foam board 301, a three-dimensional installation frame 302 and a protective film 303. The three-dimensional installation frame 302 is welded by steel bars, and no less than two layers of superimposed foam boards 301 are arranged in the three-dimensional installation frame 302. The outside of the installation frame 302 is wrapped with a protective film 303 .

[0071] The three-dimensional installation frame 302 made by welding steel bars can protect the foam board 301, and then wrap it with a protective film 303 made of fiber cloth, which can increase the structural strength of the insulation layer 3 and prevent debris, insects and other debris from entering the foam The foam board 301 is erod...

Embodiment 3

[0072] Embodiment three, please refer to Figure 5-6 , this embodiment provides a technical solution: Assembled thermal insulation building panels, this embodiment is roughly the same as the above embodiment, the difference lies in the thermal insulation layer 3;

[0073] The insulation layer 3 includes a slot plate 1 311, a longitudinal partition 312, a transverse partition 313, foam particles 314, a cover plate 315 and bolts 316, and the slot of the slot plate 1 311 passes through equidistant criss-cross longitudinal partitions 312 and transverse partitions. 313 is divided into grids, and the grids are filled with foam particles 314 , and the port of slot plate 1 311 is fixedly connected with cover plate 315 by bolts 316 .

[0074] Use the slot plate 311 to hold the foam particles 314 that play the role of heat preservation, use the longitudinal partition 312 and the transverse partition plate 313 to separate the foam particles 314, ensure the stability of the foam particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com