Anti-pulling type pipe pile and construction process thereof

A technology of anti-pull and pipe piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., and can solve the problems of easy corrosion of the welding joints of pipe pile connection end plates, reduced bearing capacity of pipe piles, insufficient pullout bearing capacity, etc. Problems, to achieve the effect of simple connection structure, improved pull-out bearing capacity, and good coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

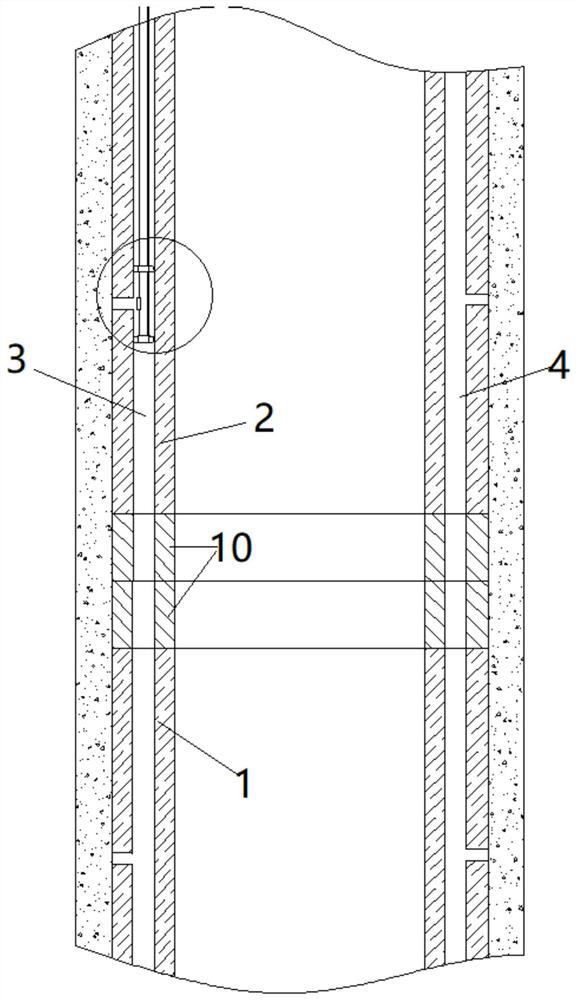

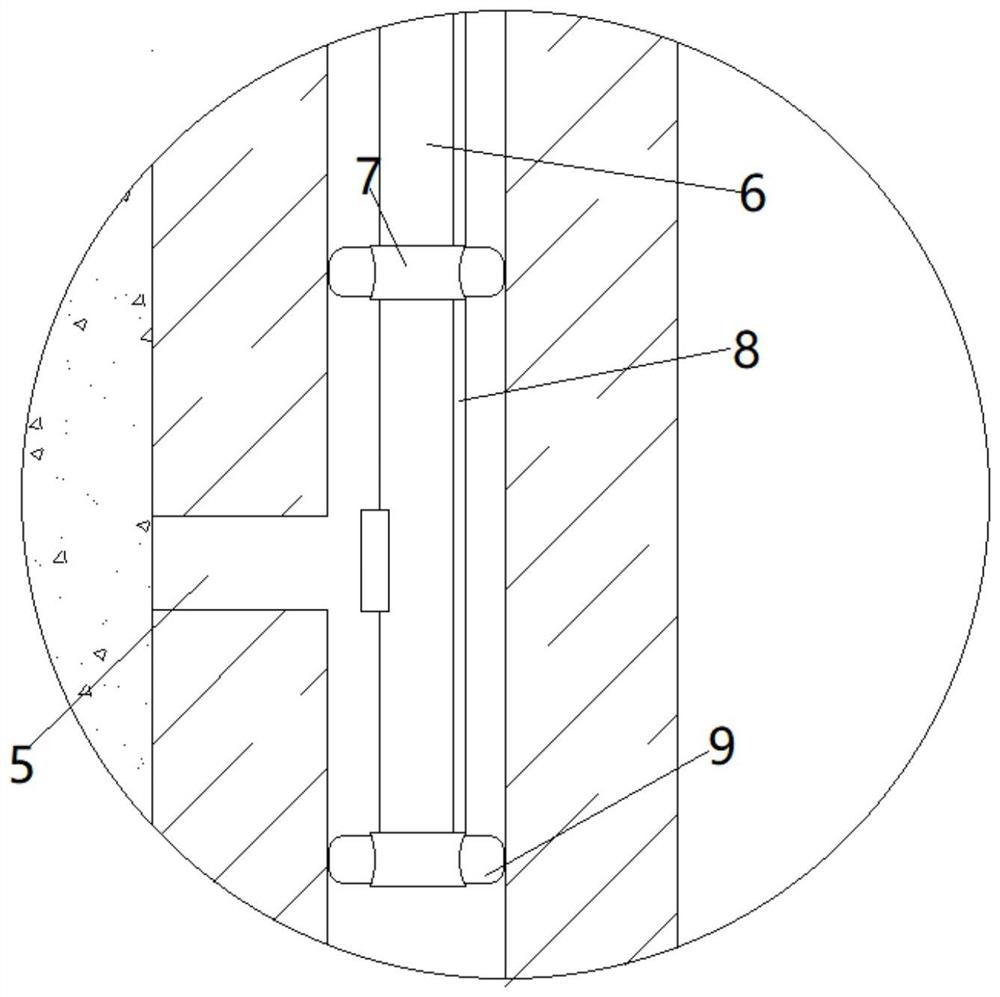

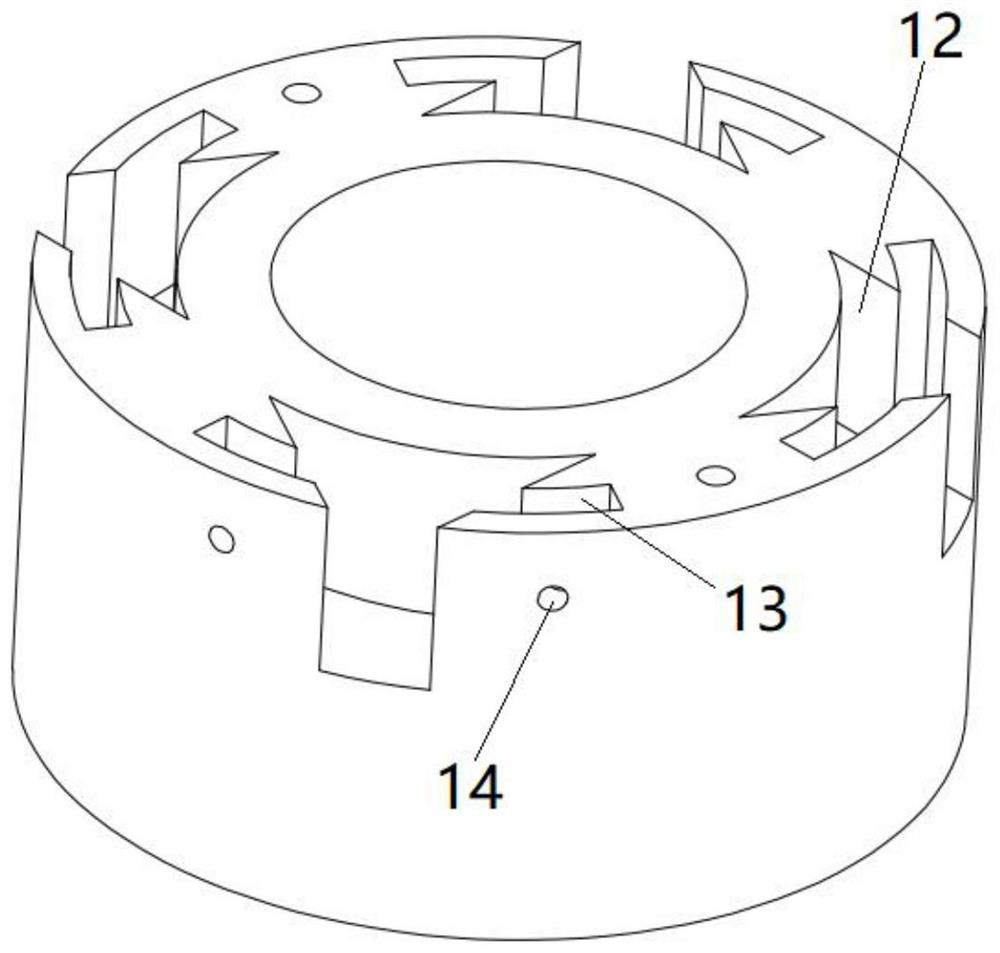

[0028] Such as Figure 1-6 As shown, the present invention discloses an anti-pull pipe pile, including a pipe pile, a connecting end plate 10 and a high-pressure grouting device. The inner cavity of the pile surrounded by the pile body is equipped with a reinforcement cage made of steel bars, and the two opposite side faces inside the pile body are respectively embedded with the first grouting pipe 3 and the second grouting pipe 4, the first grouting pipe 4 Both the grouting pipe 3 and the second grouting pipe 4 run through the entire pile body, and the outer wall of the pipe pile is provided with a number of grouting holes 5, the grouting holes 5 communicate with the first grouting pipe 3 and the second grouting pipe 4, and the surface of the pile body It is coated with silane paint, and after the silane paint is air-dried, it is coated with cement-based permeable crystalline waterproof paint to improve the durability of concrete. Two sets of grouting pipes are symmetrically ...

Embodiment 2

[0032] A construction technique for an anti-pull pipe pile, comprising:

[0033] a. According to the surrounding environment and soil conditions, choose the hammering method or the static pressure method for construction, check whether the high-pressure grouting pipe is blocked, and ensure that the high-pressure grouting pipe is unobstructed;

[0034] b. Press the lower pipe pile 1 into the soil layer by hammering method or static pressure method. When the upper end of the lower pipe pile 1 is 1m away from the surface of the soil layer, connect the upper and lower pipe piles through the connecting end plate 10, and place the upper pipe pile 2 The tenon 11 is inserted into the mortise 12 of the lower pipe pile 1, the latch is inserted into the joint end plate 10, and the connection end plate 10 is welded;

[0035] c. Carry out the pile delivery according to the design requirements, wait for the pipe pile to go deep into the designated position, extend the high-pressure grouting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com