Paste slurry drilling, grouting and impact extrusion expanded-head anchor rod structure system and construction method thereof

A construction method and head-enlarging technology, which are used in infrastructure engineering, soil protection, sheet pile walls, etc., can solve problems such as difficulty in ensuring the quality of anchoring, unclean hole cleaning for lower anchors, and difficulty in forming holes for wall protection. Creep amount, convenient construction, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

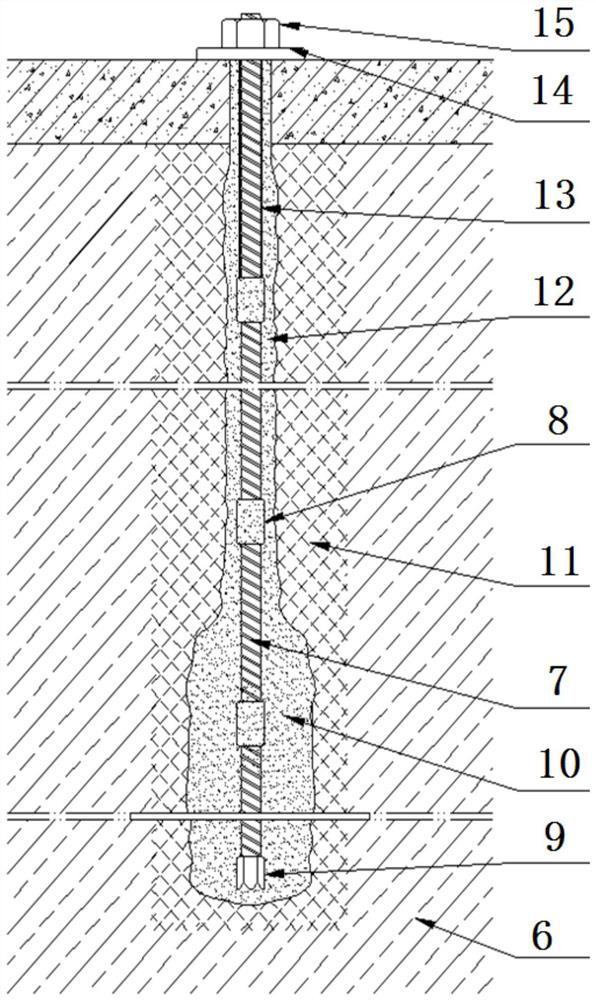

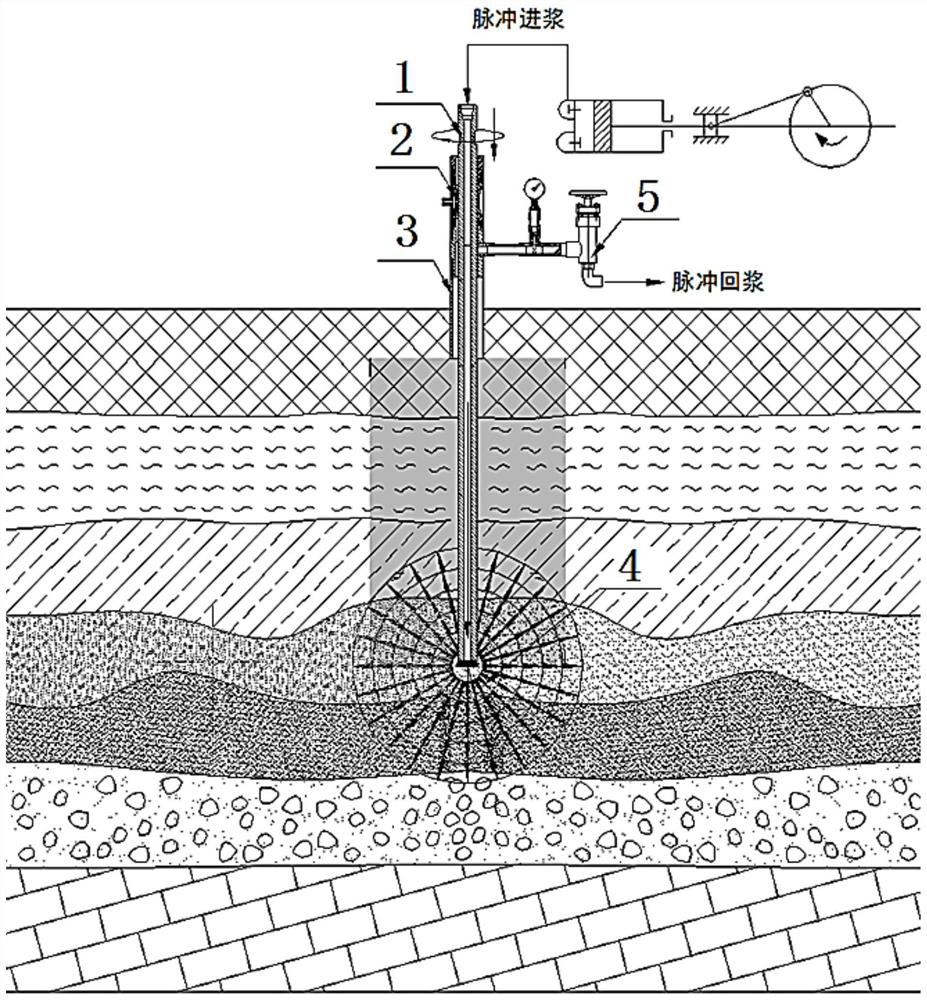

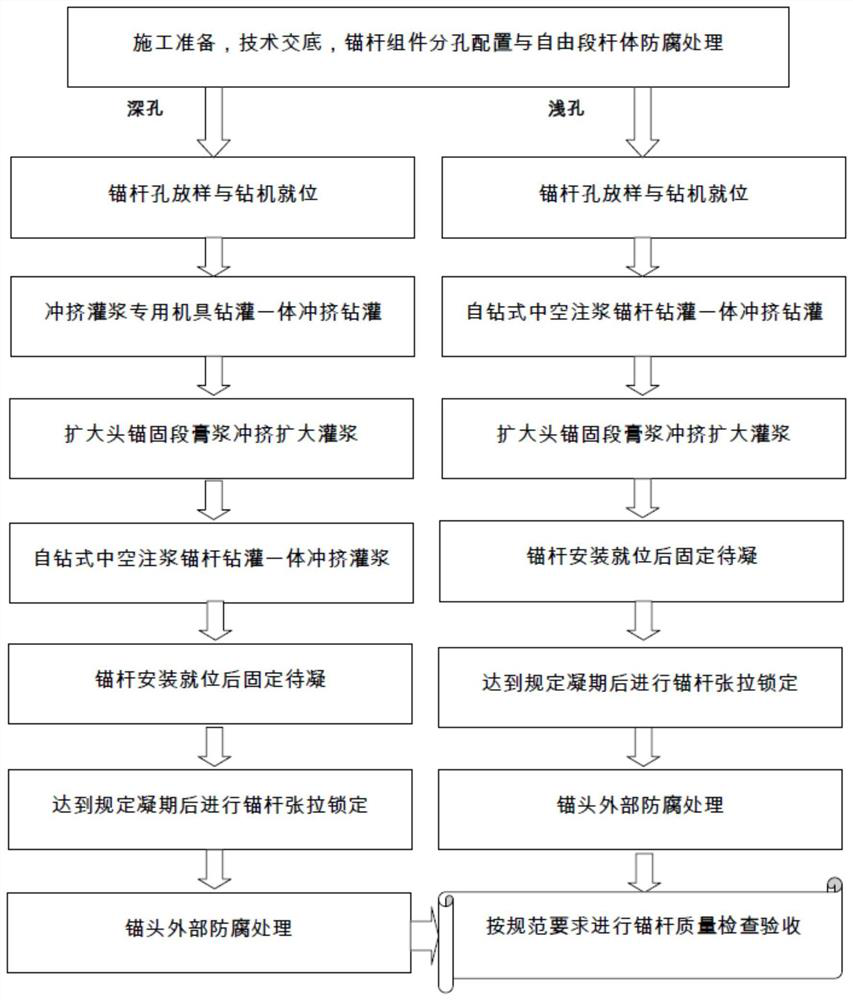

[0029] A structure system and construction method of a grout drilling, grouting, flushing and extruding expansion head bolt, such as figure 1 As shown, it includes multi-section hollow grouting anchor rods 7 installed along the axis of the anchor hole, and the upper and lower adjacent hollow grouting anchor rods 7 are connected and communicated through anchor joints 8 . The upper non-anchor free section hollow grouting anchor has an anti-corrosion layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com