Active force control rapid assembling and adjusting method for multi-layer nested X-ray focus lens

An assembly and adjustment method and a technology of focusing mirrors, which are applied in the field of X-ray focusing mirror processing, can solve problems such as the inability to guarantee the consistency of mass assembly processes, the inability to meet multi-layer nesting adjustments, and the deformation of large-size ultra-thin lenses. Achieve consistency and reliability, save manpower, and quickly adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

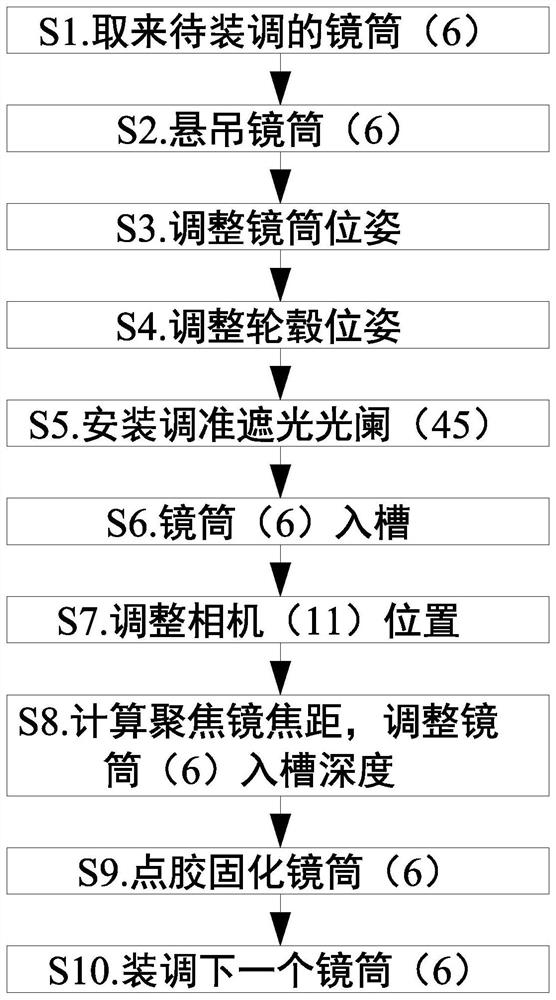

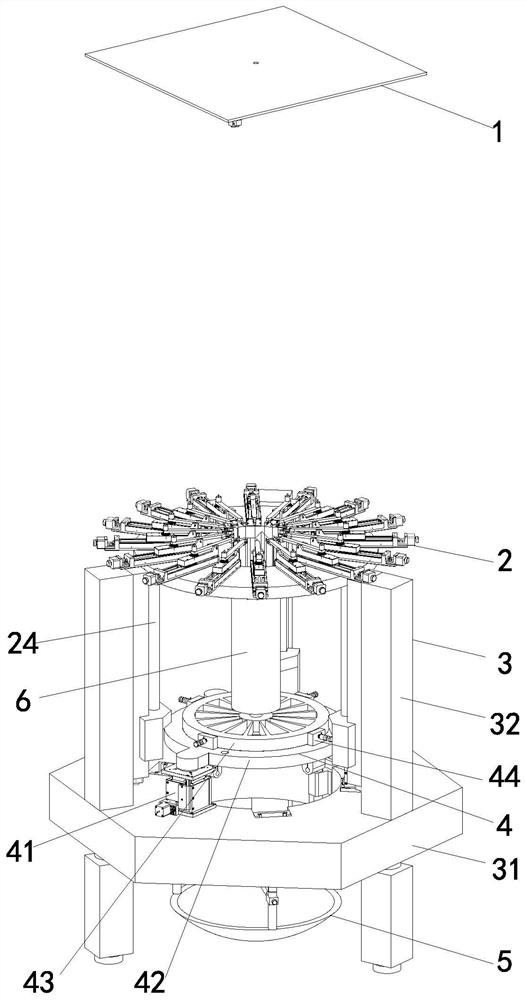

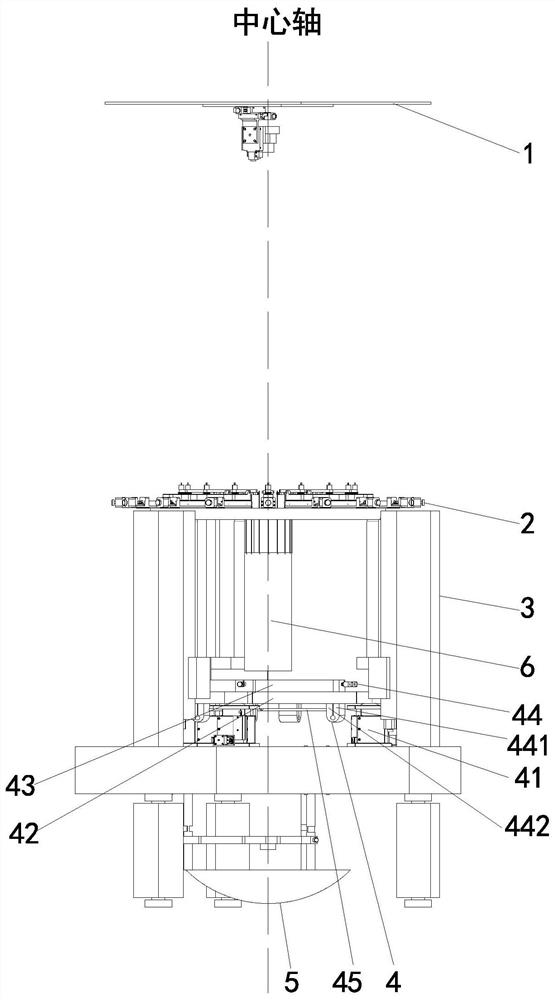

[0032] refer to Figure 1-13 The multi-layer nested X-ray focusing mirror active force control rapid adjustment method is characterized in that it includes the following steps:

[0033] S1. Take the lens barrel 6 to be adjusted;

[0034] S2. Suspend the lens barrel 6; Suspend the lens barrel 6 through the lifting plate assembly 2 of the adjusting device;

[0035] S3. Adjusting the position and posture of the lens barrel: realized by the hoisting plate assembly 2 of the adjusting device;

[0036] S4. Adjusting the hub pose: realized by the hub adjusting component 4 of the adjusting device;

[0037] S5. install and adjust the shading diaphragm 45;

[0038] S6. Lens barrel 6 into the slot;

[0039] S7. Adjust the position of the camera 11, test the pre-focus and back-focus spots, and confirm that the focusing lens is aligned;

[0040] S8. Calculate the focal length of the focusing lens, and adjust the depth of the lens barrel 6 into the groove;

[0041] S9. Glue dispensing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com