Method for detecting hardness of nickel-plated layer of lithium battery cap

A detection method, lithium battery technology, applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve the problems of inaccurate test accuracy, iron matrix hardness interference, high test cost, etc., achieve low test cost and eliminate hardness interference , Hardness testing is convenient and accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

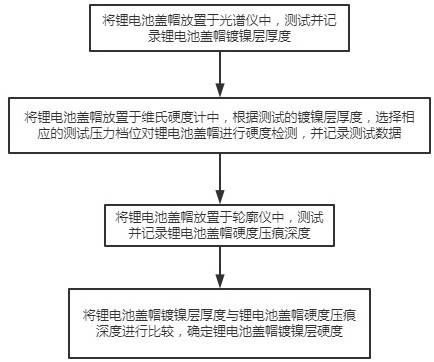

[0029] Such as figure 1 As shown, the present embodiment provides a method for detecting the hardness of the nickel-plated layer of a lithium battery cap, including:

[0030] Place the lithium battery cap in the spectrometer, test and record the thickness of the nickel-plated layer of the lithium battery cap;

[0031] Place the lithium battery cap in the Vickers hardness tester, select the corresponding test pressure gear to test the hardness of the lithium battery cap according to the thickness of the nickel plating layer to be tested, and record the test data;

[0032] Place the lithium battery cap in the profiler, test and record the hardness indentation depth of the lithium battery cap;

[0033] Compare the thickness of the nickel-plated layer of the lithium battery cap with the hardness indentation depth of the lithium battery cap to determine the hardness of the nickel-plated layer of the lithium battery cap.

[0034] The detection method provided in this embodiment el...

Embodiment 2

[0036] This embodiment provides a method for detecting the hardness of the nickel-plated layer of a lithium battery cap, including:

[0037] Place the lithium battery cap in the spectrometer to test and record the thickness of the nickel-plated layer of the lithium battery cap;

[0038] Specifically, in this embodiment, the thickness of the nickel-plated layer of the lithium battery cap is tested three times, and it is ensured that the three indentations produced by the thickness test of the nickel-plated layer of the lithium battery cap need to be on a straight line, and the average value is taken as the nickel-plated layer of the lithium battery cap. The value of the layer thickness.

[0039] This can more accurately obtain data on the thickness of the nickel-plated layer of the lithium battery cap, which is more informative.

[0040] Place the lithium battery cap in the Vickers hardness tester, select the corresponding test pressure gear to test the hardness of the lithium...

Embodiment 3

[0056] This embodiment provides a detection device for the hardness of the nickel-plated layer of a lithium battery cap, including a spectrometer, a Vickers hardness tester, and a profiler. This embodiment uses conventional laboratory testing equipment to detect the hardness of the nickel-plated layer of a lithium battery cap. There is no need to purchase special equipment or entrust an agency to conduct testing, which not only enables convenient and quick testing, but also greatly saves testing costs.

[0057] Those skilled in the art should understand that the embodiments of the present application may be provided as methods, systems, or computer program products. Accordingly, the present application may take the form of an entirely hardware embodiment, an entirely software embodiment, or an embodiment combining software and hardware aspects. Furthermore, the present application may take the form of a computer program product embodied on one or more computer-usable storage m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com