Special combined protective sleeve for shock absorber of all-terrain vehicle

An all-terrain vehicle and shock absorber technology, applied in shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of high cost, fast shock absorber loss, short life, etc. Durable, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

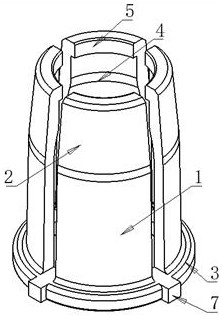

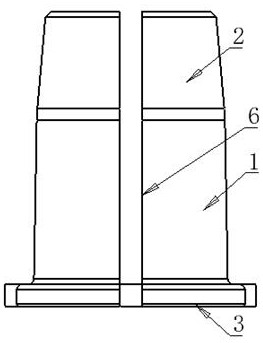

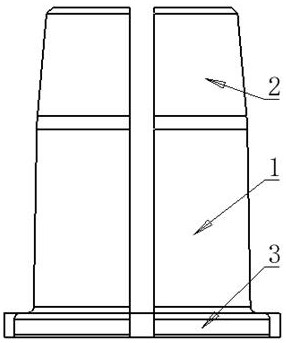

[0019] Such as Figure 1 to Figure 6 As shown, a special all-terrain vehicle shock absorber combination protective cover, which adopts a new structural design, can be installed and connected together with the combination parts of the shock absorber when in use, and can play a better role in the assembly position. Reinforcement and safety protection make the overall strength of the shock absorber better, the overall durability is stronger during use, and the service life is longer. At the same time, it can also make the maintenance period longer and the use cost lower. It includes a cylindrical main body with a central axis in the up-down direction and is fitted with a protective column 1. The upper end of the main body is fitted with a protective column 1. An integrally formed conical cooperating stable combination column 2 is provided. The lower end of the main body is installed with the protective column 1. There is an integrally formed cylindrical matching stop stabilizing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com