Low-energy-consumption high-pollution-resistance ultrahigh-frequency-response digital hydraulic servo control system and control method

A servo control system, digital hydraulic technology, applied in the direction of fluid pressure actuation system components, servo motors, servo motor components, etc., can solve the complex structure of hydraulic servo control system, the control is susceptible to environmental interference, operation and maintenance requirements and high costs problem, to achieve the effect of good dynamic and static characteristics, small inertial force and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

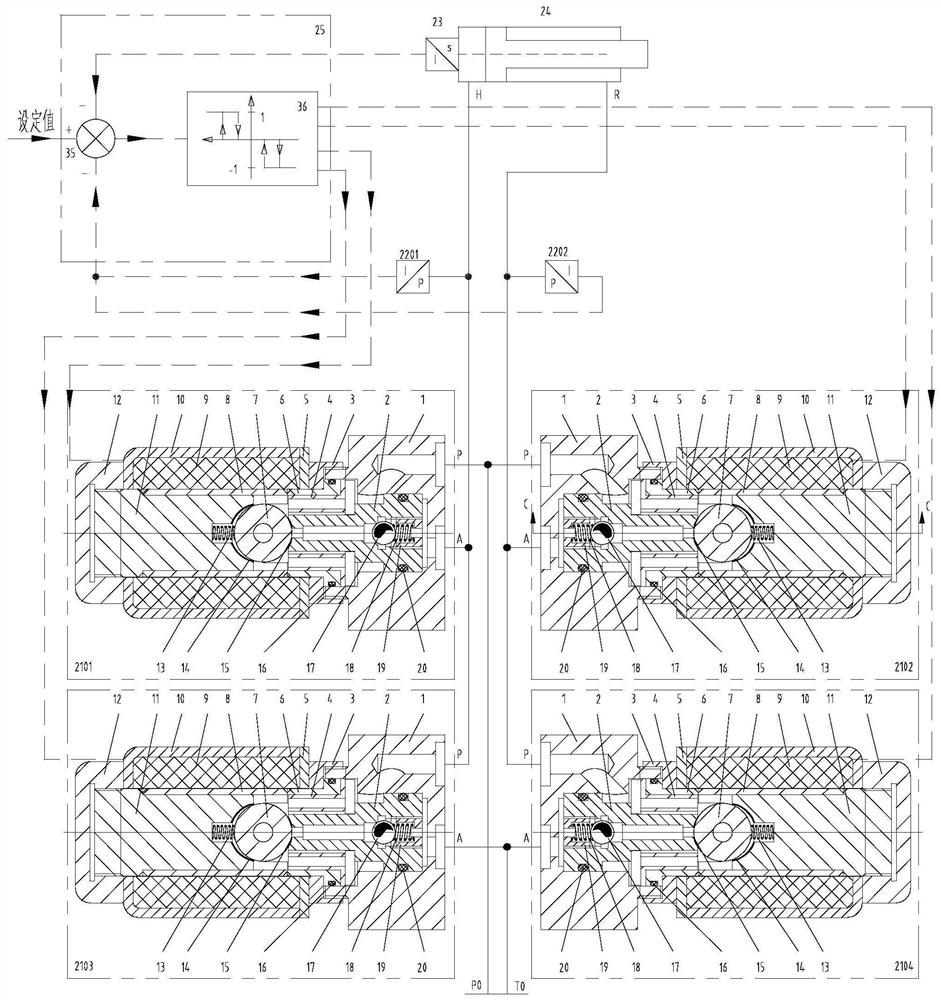

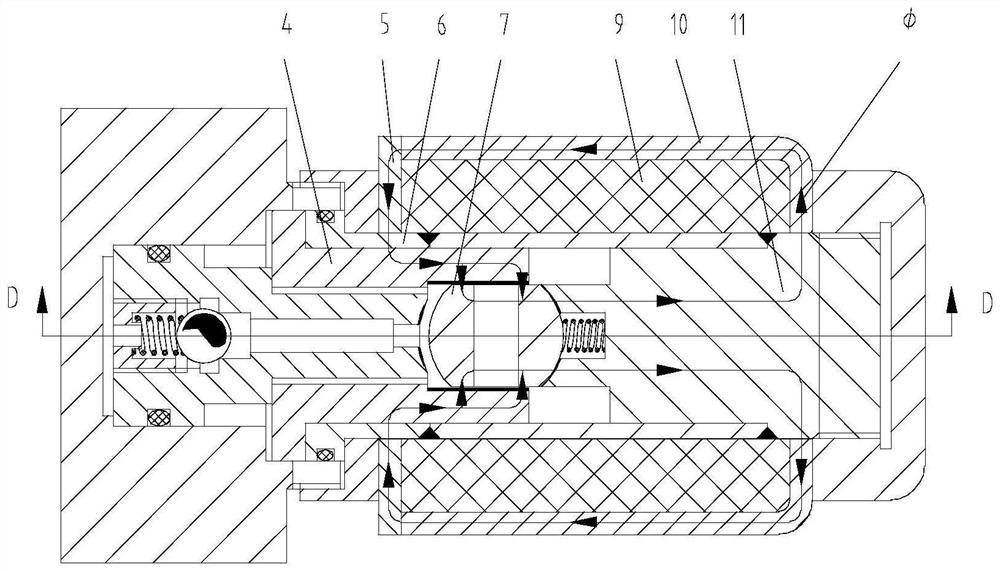

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention is a digital hydraulic servo control system with low energy consumption, high pollution resistance and ultra-high frequency response, including a first digital hydraulic switch valve 2101, a second digital hydraulic switch valve 2102, a third digital hydraulic switch valve 2103, and a fourth digital hydraulic switch valve. Hydraulic switching valve 2104, hydraulic cylinder 24, displacement sensor 23, first pressure sensor 2201, second pressure sensor 2202 and digital controller 25, displacement sensor 23 is arranged on the end of hydraulic cylinder 24, and digital controller 25 comprises the connected comparator Device 35 and digital signal generator 36;

[0031] The main pressure oil P0 is respectively connected with the main pressure oil port P of the first digi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com