Series of ethylene diammonium ternary crystalline compounds, preparation method thereof and application of ethylene diammonium ternary crystalline compounds as energetic materials

A compound, the technology of fatty diammonium, which is applied in the field of a series of ethylenediammonium ternary crystalline compounds and its preparation, can solve the problems of low thermal stability and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

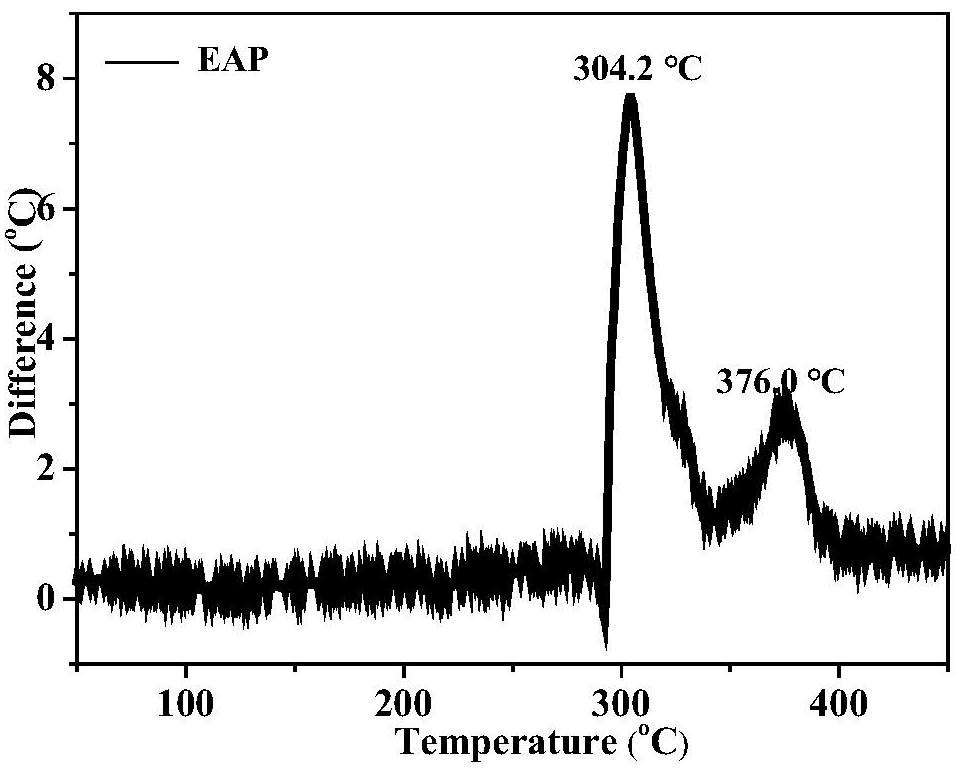

[0136] (H 2 EA) 2 (NH 4 ) (ClO 4 ) 5 (EAP) synthesis and testing

[0137] (Formula B 2 A'X 5 , A is NH 4 + , B is ethylenediammonium cation H 2 EA 2 2+ , X is ClO 4 - )

[0138] resolve resolution:

[0139] 1) Add 7.14g of perchloric acid solution with a mass fraction of 70%–72% into 1mL of water and stir evenly;

[0140] 2) Add 1.20g of ethylenediamine into 4mL of water and stir evenly;

[0141] 3) Mix the solutions of step 1) and step 2), stir for 10 minutes, then add 1.4 g of 25% ammonia solution while stirring, stir for 30 minutes, filter, wash the precipitate with acetone, and dry it in vacuum to obtain a solid powder. It was identified as EAP pure phase by powder diffraction, and the yield was 80%.

[0142] Powder X-ray Diffraction Identification Pattern:

[0143] The powder X-ray diffraction pattern at room temperature is shown in image 3 .

[0144] Single crystal structure characterization test:

Embodiment 2

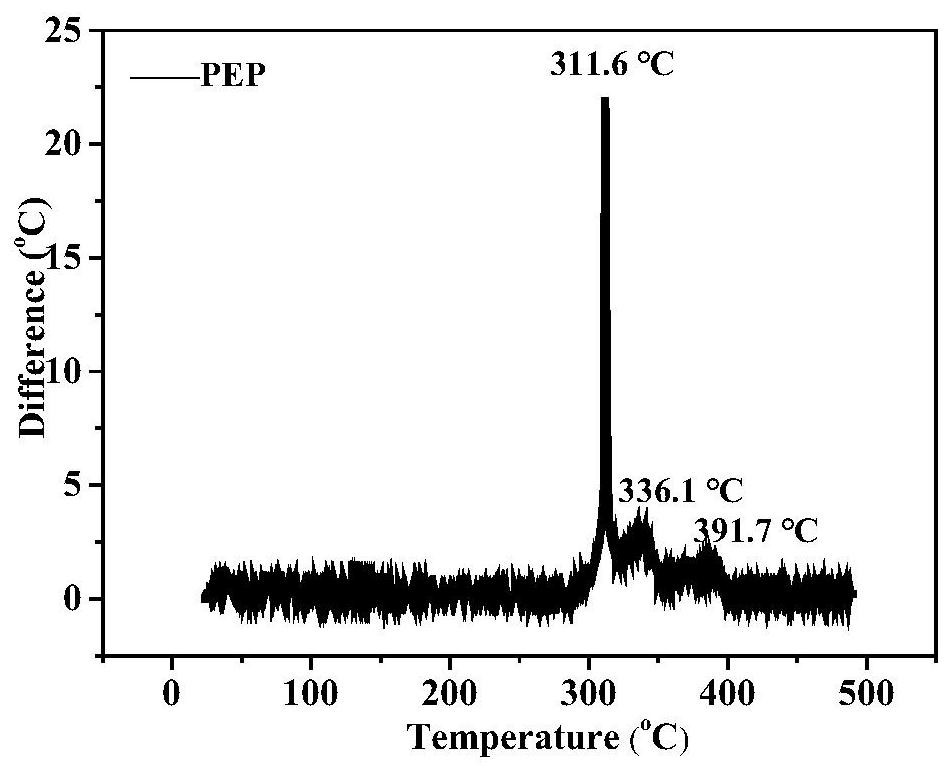

[0158] (C 4 h 12 N 2 )(H 2 EA) (ClO 4 ) 4 (PEP) synthesis and testing

[0159] (general formula ABX 4 , A is piperazine-1,4-dinium ion, B is ethylenediammonium cation H 2 EA 2 2+ , X is ClO 4 - )

[0160] resolve resolution:

[0161] 1) Add 11.43g of perchloric acid solution with a mass fraction of 70%–72% into 15mL of water, add 1.20g of ethylenediamine under stirring, and stir at room temperature for 5 minutes;

[0162] 2) Add 1.72g of anhydrous piperazine into 5mL of water to dissolve;

[0163] 3) Mix the solutions of step 1) and step 2), stir for 10 min, filter, wash the precipitate with ethanol, and dry in vacuum to obtain a solid powder, which is identified as a pure phase of PEP by X-ray powder diffraction, with a yield of 85%.

[0164] Powder X-ray Diffraction Identification Pattern:

[0165] The powder X-ray diffraction pattern at room temperature is shown in Figure 5 .

[0166] Single crystal structure characterization test:

[0167] For a schemati...

Embodiment 3

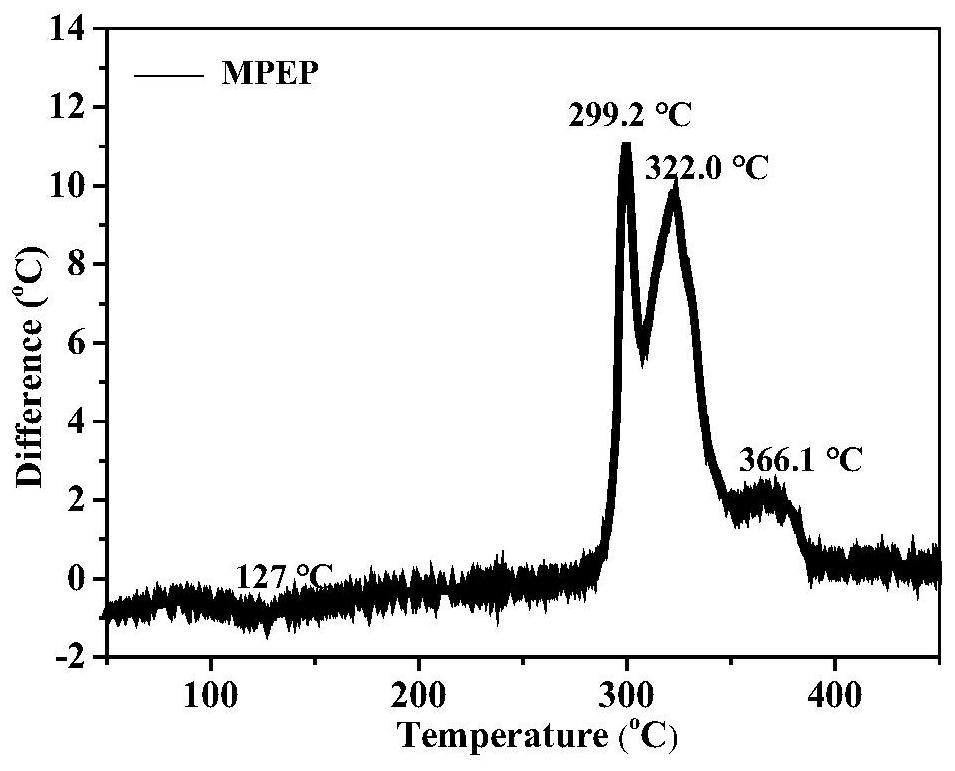

[0179] (C 5 h 14 N 2 )(H 2 EA) (ClO 4 ) 4 Synthesis and testing of (MPEP)

[0180] (general formula ABX 4 , A is 1-methylpiperazine-1,4-dinium ion, B is ethylenediammonium cation H 2 EA 2 2+ , X is ClO 4 - )

[0181] resolve resolution:

[0182] 1) Add 11.43g of perchloric acid solution with a mass fraction of 70%–72% into 15mL of water, add 1.20g of ethylenediamine under stirring, and stir at room temperature for 5 minutes;

[0183] 2) Add 2.00g of 1-methylpiperazine into 5mL of water to dissolve;

[0184] 3) Mix the solutions of step 1) and step 2), stir for 10 min, filter, wash the precipitate with ethanol, and dry in vacuum to obtain a solid powder, which is identified as MPEP pure phase by X-ray powder diffraction, with a yield of 80%.

[0185] Powder X-ray Diffraction Identification Pattern:

[0186] The powder X-ray diffraction pattern at room temperature is shown in Figure 7 .

[0187] Single crystal structure characterization test:

[0188] Detailed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com