Adjustable limiting and fixing method for special-shaped component

A technology for special-shaped components and fixing methods, which is used in clamping, positioning devices, maintenance and safety accessories, etc., can solve the problems of rigid specifications of fixed components, lack of adjustment mechanisms for special-shaped components, and lack of fixing methods for special-shaped components, and achieves good limits. Bit and fixed processing, flexible and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

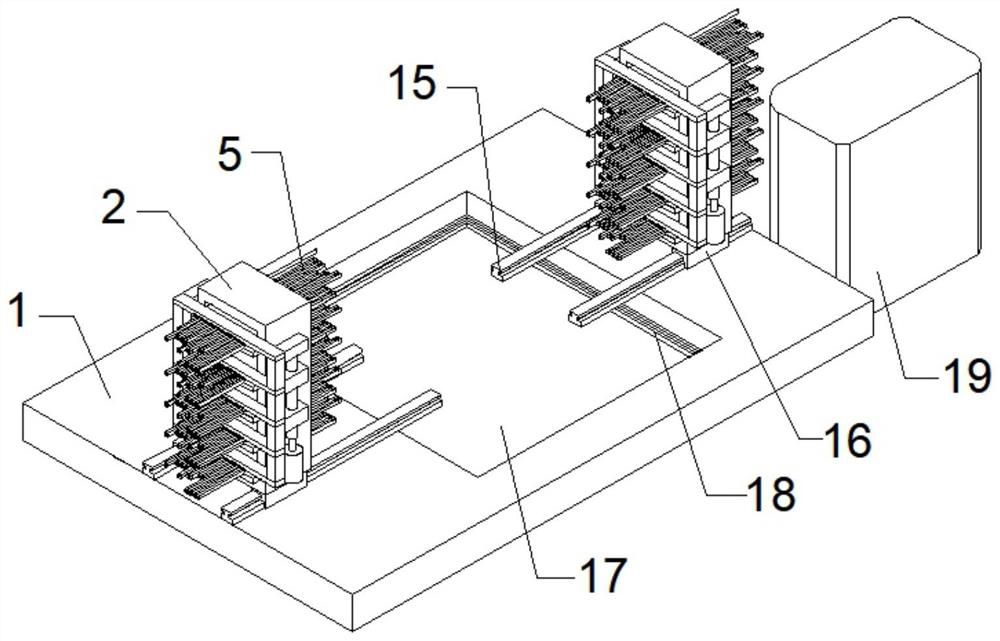

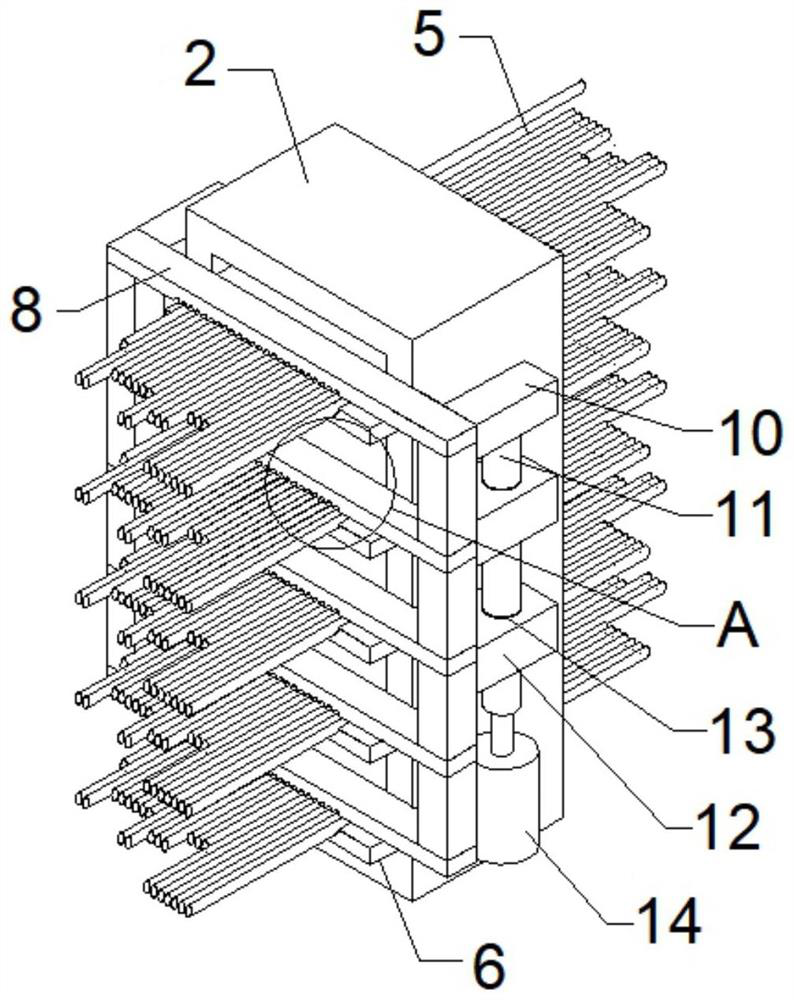

[0027] Such as Figure 1-4 As shown, an adjustable limit and fixing method for special-shaped components includes the following fixing methods:

[0028] Step 1: Build an adjustable limit and fixing mechanism

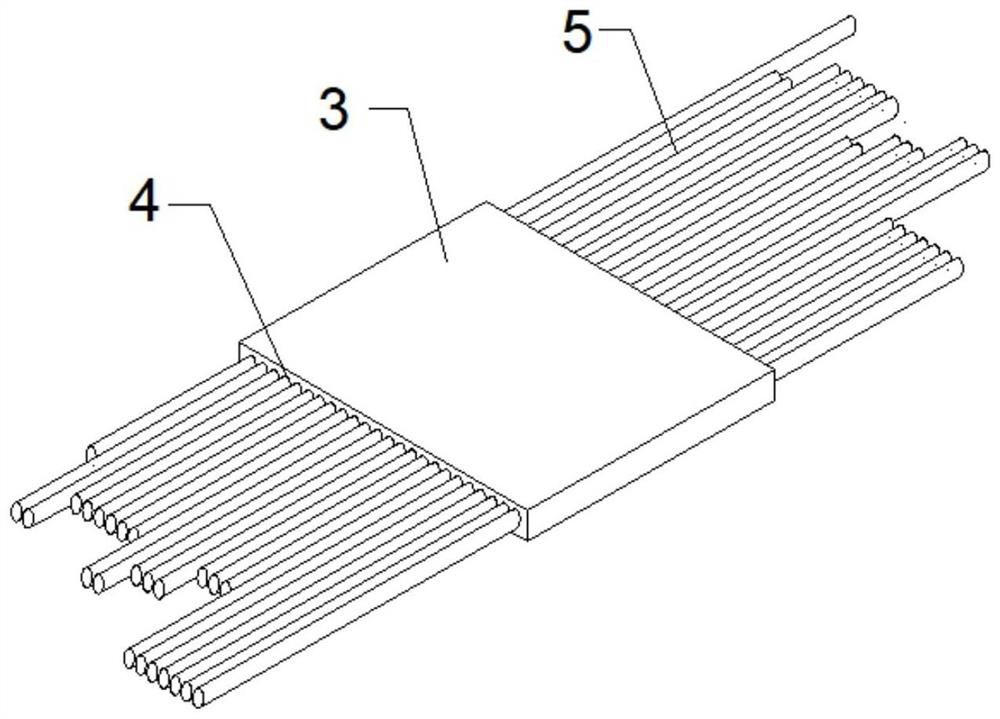

[0029] 1), the adjustable limit and fixation mechanism includes a component support platform 1, the adjustment frame 2 and the positioning rod 5, the adjustable limit and fixation mechanism also includes a hydraulic push rod 14 and a guide rod 11, and the component support platform 1 is set There is a work tank 17, and the two ends of the top of the component support platform 1 are respectively provided with an adjustment frame 2, and the bottom and top of the adjustment frame 2 are welded and connected with rod boxes 3, and the inside of the rod box 3 is distributed with openings and positioning The rod hole 4 corresponding to the rod 5;

[0030] 2), the back of the adjustment frame 2 and the bottom of the positioning rod 5 are all provided with a lower support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com