Water-free closestool

A waterless toilet and component technology, which is applied in the field of sanitary products, can solve the problems of single screw mode and inability to combine discharge functions, etc., and achieve the effect of flexible selection, good air treatment effect, and reduction of environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

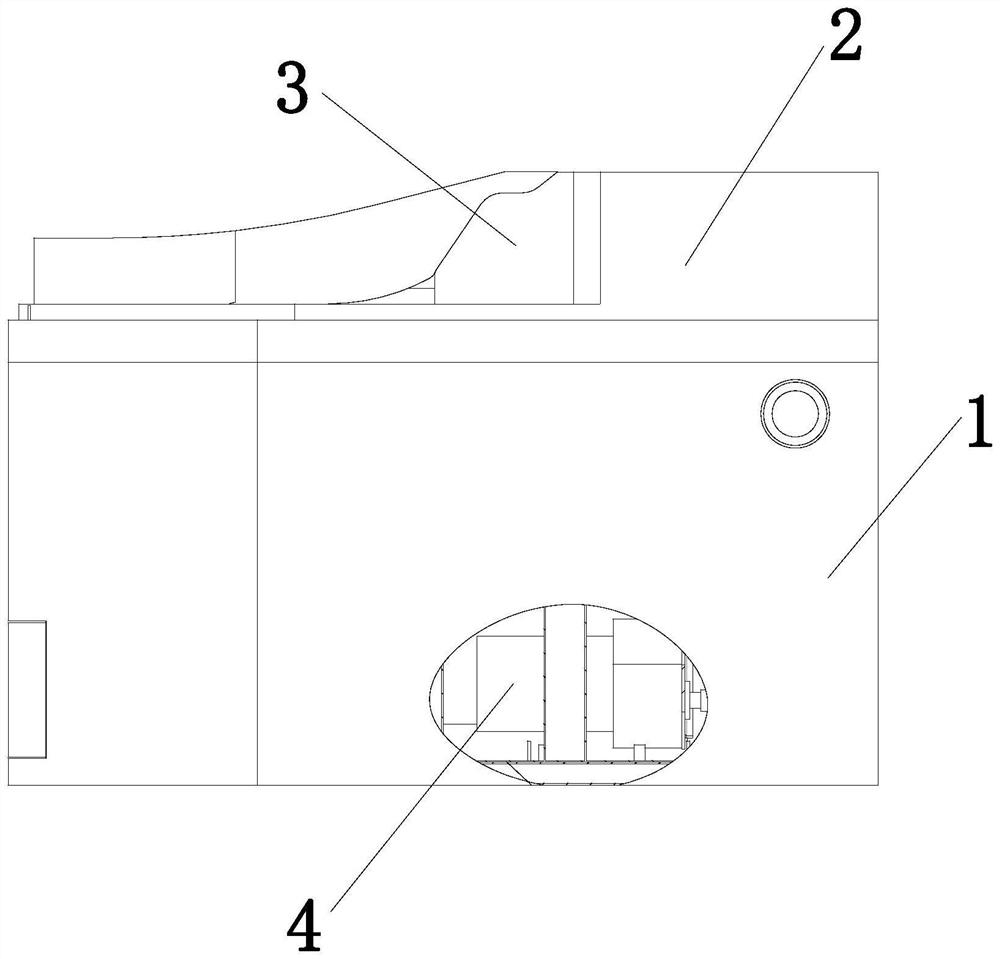

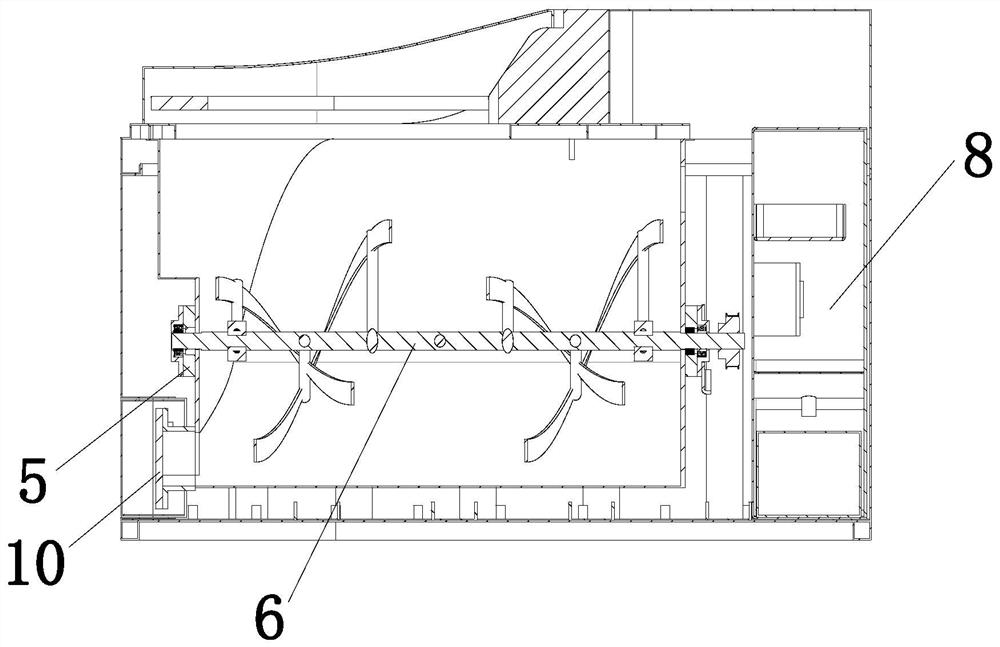

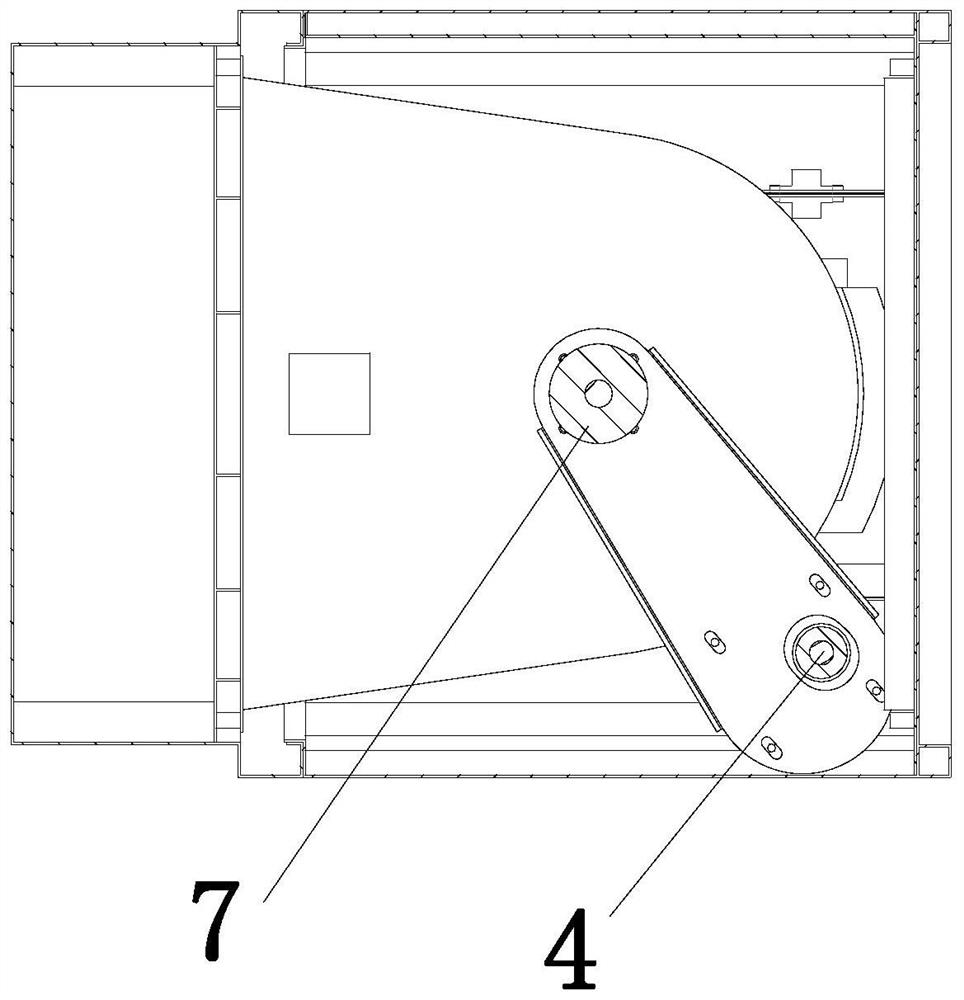

[0033] Such as Figure 1-Figure 9 As shown, a waterless toilet includes a processor housing 1, an upper cover 2 arranged on the processor housing 1 and a toilet cover 3 connected to the upper cover 2, and also includes a drive motor 4 and a bearing seat 5 provided The spiral stirring assembly 6 inside the processor housing 1, the drive motor 4 is connected to the spiral stirring assembly 6 through a synchronous pulley assembly 7 and drives the spiral stirring assembly 6 to run, and the processor housing 1 is provided with a bearing seat 5 A discharge port 10 is provided at a position close to the bottom of one of the outer sidewalls, and a discharge assembly 9 is provided on the discharge port 10, and an end of the outer wall of the processor housing 1 away from the discharge assembly 9 is provided with a processing The air treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com