High-voltage power transmission line detonating cord fixing device

A technology of high-voltage transmission lines and high-voltage transmission lines, which is applied in the installation of cables, overhead installations, electrical components, etc., can solve the problems of deicing failure, deformation of transmission towers, damage to power grids, etc., and achieves simple and practical installation and good mechanical reliability. , the effect of good plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

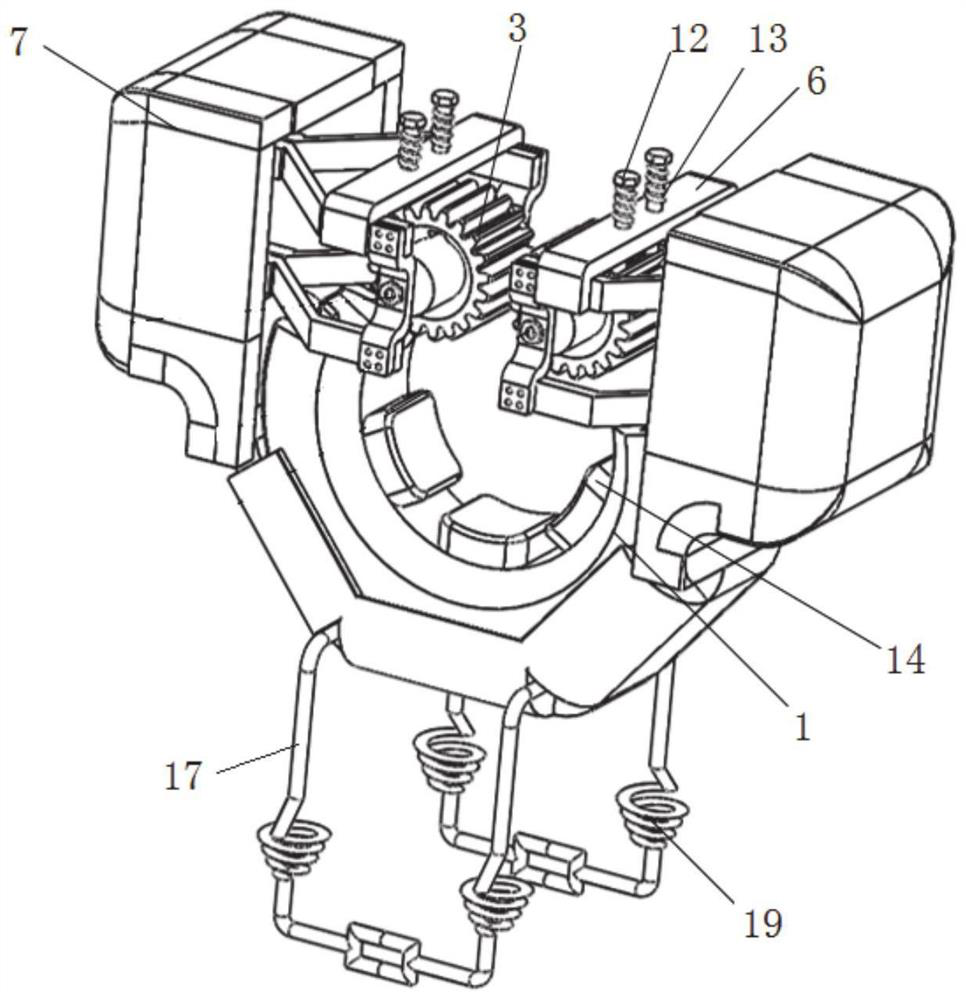

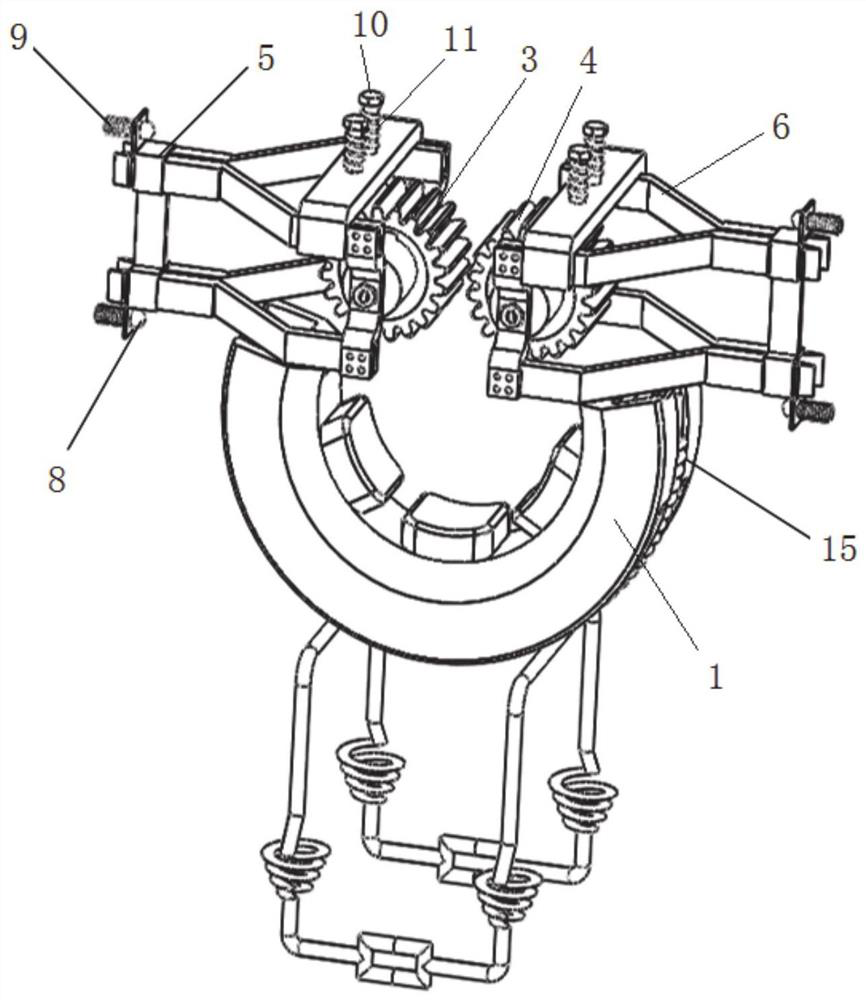

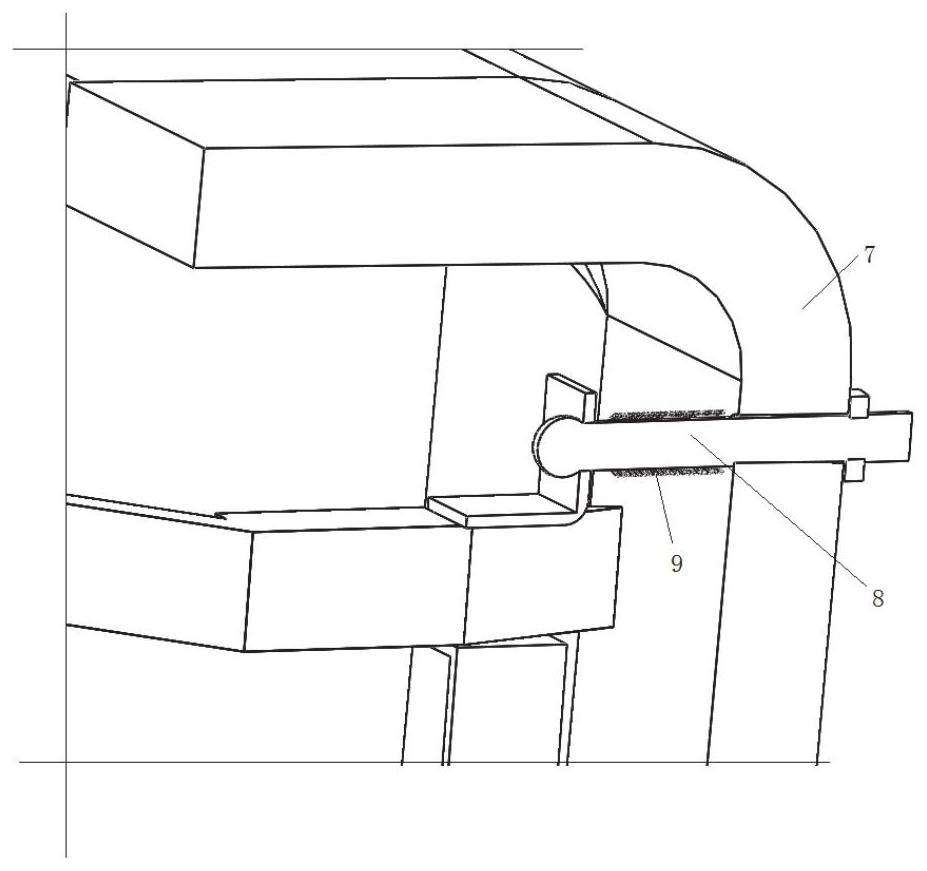

[0034] This embodiment provides a high-voltage transmission line detonating cord fixing device, such as Figure 1-Figure 6 As shown, it includes a fixing piece 1, which is used to lock and fix the high-voltage transmission line 2. In this embodiment, the fixing piece 1 adopts a ring-shaped shell structure with a gap on the top, which has a The space for accommodating the high-voltage transmission line 2 , the high-voltage transmission line 2 can enter the interior of the fixing piece 1 from the gap at the top of the fixing piece 1 , and then the fixing piece 1 and the high-voltage transmission line 2 are locked and fixed.

[0035] The first gear 3 and the second gear 4 used in pairs are arranged above the fixed part 1, the axes of the first gear 3 and the second gear 4 are arranged parallel to the axis of the fixed part 1, and the first gear 3 and the second gear The two gears 4 can move towards or away from each other.

[0036] The first gear 3 is rotatably connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com