Reflective dimming glass based on electric response and preparation method

A dimming glass, electrical response technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of easy damage to polymer networks, poor mechanical properties of thin films, short service life, etc., to achieve long service life, not easy to damage , the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

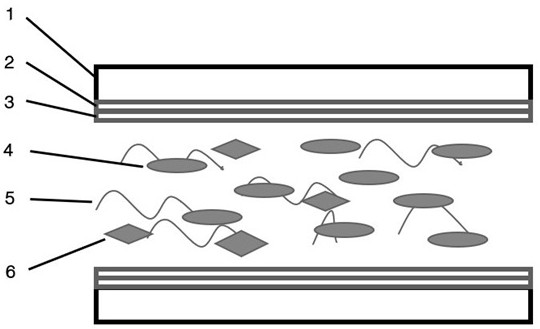

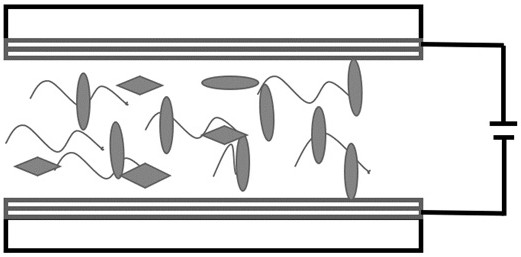

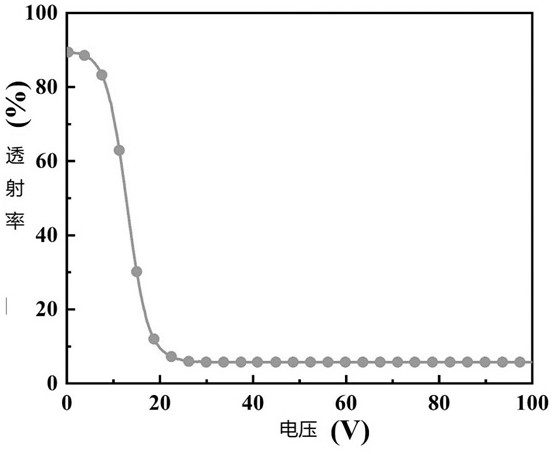

[0041] Prepare two transparent substrates 1 that are all coated with a layer of conductive ITO coating 2. The transparent substrate 1 is made of glass, and a flat orientation layer is coated on the surface of the conductive ITO coating 2 of the transparent substrate 1 respectively; The parallel alignment layers 3 of the transparent substrate 1 are arranged opposite to each other, and spacer particles that control the thickness of the interlayer space are mixed in the middle to make a liquid crystal 4 cell; take 20 parts by mass of a liquid crystal polymerizable monomer and 10 parts by mass of a non-liquid crystal polymerizable monomer , 2 parts by mass of photoinitiator, and 68 parts by mass of liquid crystal 4, after weighing, the mixture is heated to 70°C in a yellow light environment without ultraviolet light, so that the liquid crystal 4 is transformed into an isotropic state. At this temperature, inject the liquid crystal 4 mixed solution into the liquid crystal 4 box, and...

Embodiment 2

[0044] Prepare two transparent substrates 1 that are all coated with a layer of conductive ITO coating 2. The transparent substrate 1 is made of glass, and a flat orientation layer is coated on the surface of the conductive ITO coating 2 of the transparent substrate 1 respectively; The parallel alignment layers 3 of the transparent substrate 1 are oppositely arranged, and spacer particles controlling the thickness of the interlayer space are mixed in the middle to form a liquid crystal 4 cell; take 5 parts by mass of liquid crystal polymerizable monomers and 5 parts by mass of non-liquid crystal polymerizable monomers , 1 part by mass of photoinitiator, and 89 parts by mass of liquid crystal 4. After weighing, the mixture is heated to 70°C under a yellow light environment without ultraviolet light, so that the liquid crystal 4 is transformed into an isotropic state. At this temperature, inject the liquid crystal 4 mixed solution into the liquid crystal 4 cell, and keep it warm ...

Embodiment 3

[0047] Prepare two transparent substrates 1 that are all coated with a layer of conductive ITO coating 2. The transparent substrate 1 is made of glass, and a flat orientation layer is coated on the surface of the conductive ITO coating 2 of the transparent substrate 1 respectively; The parallel alignment layers 3 of the transparent substrate 1 are arranged opposite to each other, and spacer particles that control the thickness of the interlayer space are mixed in the middle to make a liquid crystal 4 cell; take 10 parts by mass of a liquid crystal polymerizable monomer and 10 parts by mass of a non-liquid crystal polymerizable monomer , 2 parts by mass of photoinitiator, and 78 parts by mass of liquid crystal 4. After weighing, the mixture is heated to 70°C in a yellow light environment without ultraviolet light, so that the liquid crystal 4 is transformed into an isotropic state. At this temperature, inject the liquid crystal 4 mixed solution into the liquid crystal 4 cell, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com