Light-adjustable colored glaze glass and processing method thereof

A processing method and glass technology, applied in chemical instruments and methods, glass/slag layered products, lamination auxiliary operations, etc., can solve the problems of high energy consumption, achieve the effect of simplifying the process and protecting privacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

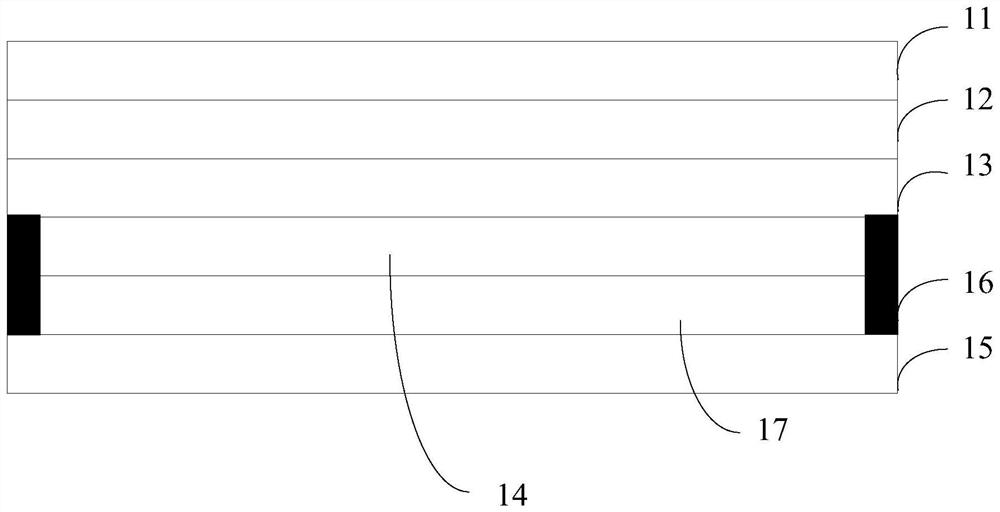

[0018] The present invention proposes a method for processing light-adjustable glazed glass comprising the following steps:

[0019] Printing a UV ink layer on the first glass substrate, and irradiating and curing it under ultraviolet light to make a colored glaze glass plate;

[0020] A PDLC dimming film is pasted on the second glass substrate to make a dimming board;

[0021] Coating the side of the PDLC dimming film away from the second glass substrate with an OCA adhesive layer;

[0022] Laminating the side of the first glass substrate on which the UV ink layer is printed and the PDLC dimming film;

[0023] The OCA adhesive layer is cured so that the colored glaze glass plate is closely connected with the dimming plate.

[0024] In the present invention, by using UV ink instead of traditional inorganic glaze, the process of heat treatment and sintering is reduced during the processing of colored glaze glass, and the effect of simplifying the process, energy saving and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com