Carrier for heating test of electronic device

A technology for electronic devices and carriers, applied in the field of electronic device heating test carriers, can solve the problems of increasing the time and cost of testing electronic devices, failing to timely feedback the temperature of electronic devices, and low temperature control accuracy, and reducing time and heating time. Short, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

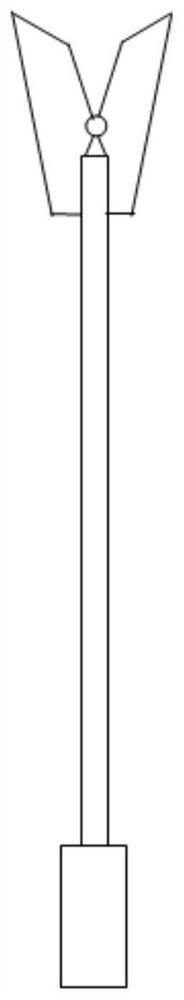

[0034] Embodiment 1 is basically as attached figure 1 Shown:

[0035] An electronic device heating test carrier, such as figure 1 , figure 2 As shown, it includes a carrier 1 , a heating device, a temperature sensor 2 , a humidity sensor 4 , a controller 5 , a test base 6 and a substrate 3 . The carrier 1 , the temperature sensor 2 , the humidity sensor 4 and the controller 5 are all arranged on the substrate 3 .

[0036] The carrier 1 is used to load the device to be tested, and when it is necessary to conduct an electronic device test, the device to be tested is fixedly connected to the carrier 1 . In this embodiment, the way of fixed connection is welding. In other embodiments of the present application, the device under test may also be fixed on the carrier 1 by using special adhesive for electronic components.

[0037] The heating device includes a heating top plate and a heating bottom plate, and the heating top plate and the heating bottom plate are used to clamp a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com