Rapid and automatic strain gauge pasting device for structural safety detection

A technology of safety detection and strain gage, which is applied in the direction of electromagnetic measuring device, electric/magnetic solid deformation measurement, etc., can solve the problems of large amount of manual operation, influence of pasting modules on work effect and work process, etc., so as to reduce workload and facilitate Recycling and reuse, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The invention provides a device for quickly and automatically pasting strain gauges for structural safety detection, which reduces the workload of manual operations, improves the work quality, enhances the work precision and promotes the work efficiency.

[0042] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below in conjunction with the accompanying drawings, and the protection scope of the present invention is not limited to the following description:

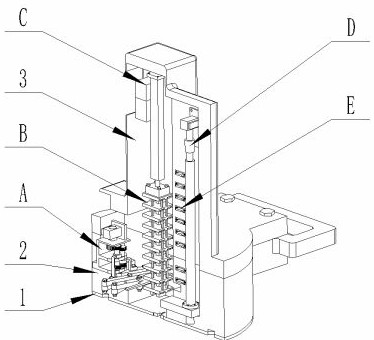

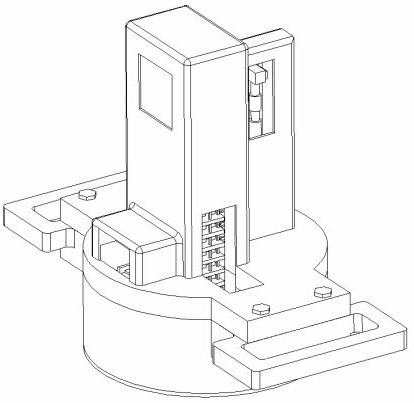

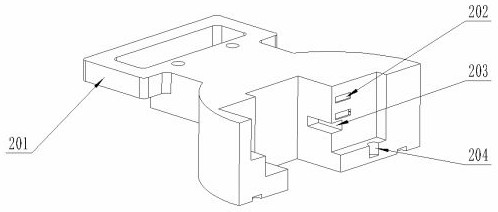

[0043] refer to figure 1 and figure 2 , figure 1 It is a structural schematic diagram of a fast and automatic strain gage device for structural safety detection in an example of the present invention; figure 2 Half-cut the upper shell, lower shell and magnetic base to show the internal structure of the device.

[0044] 1. If Figure 1 to Figure 15 As shown, a fast and automatic strain gauge attachment devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com