Wave-absorbing material derived from NiCo-MOF/biomass cotton and preparation method thereof

A wave-absorbing material and biomass technology, applied in carbon preparation/purification, metal processing equipment, transportation and packaging, etc., can solve problems such as narrow effective absorption bandwidth, complex synthesis process, expensive raw materials, etc., and achieve improved electromagnetic wave absorption performance , Simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

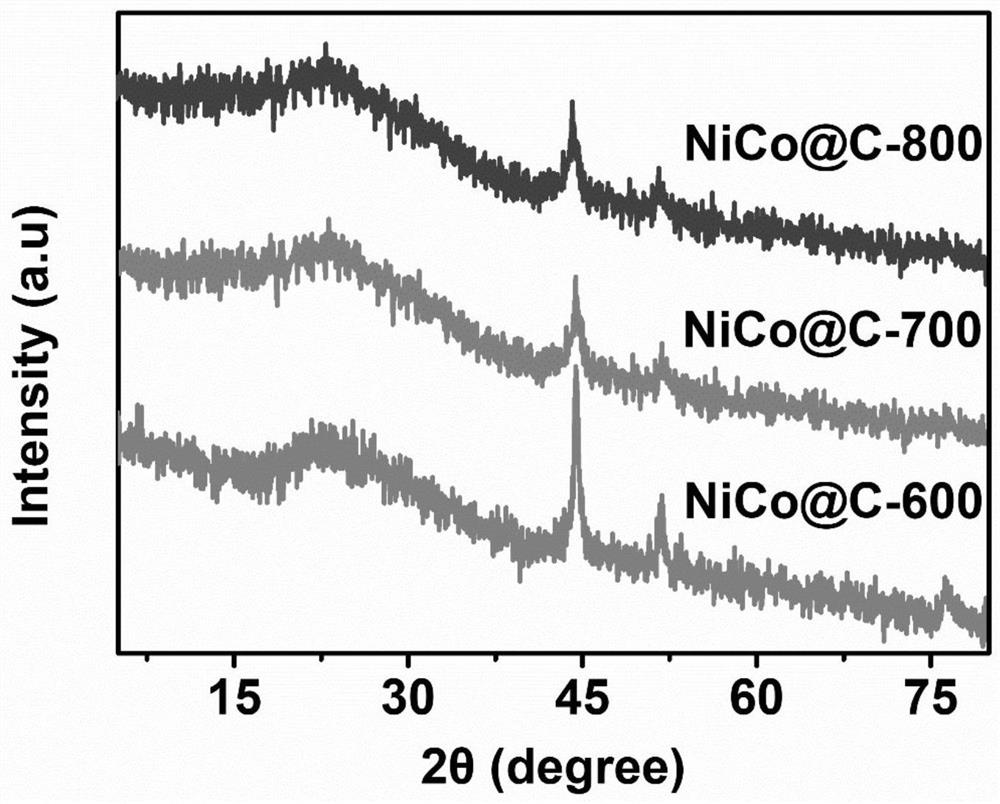

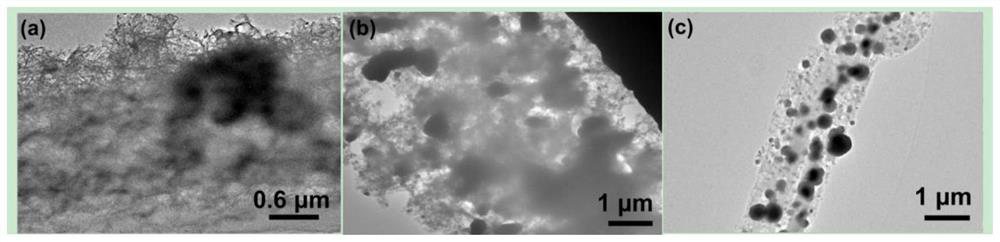

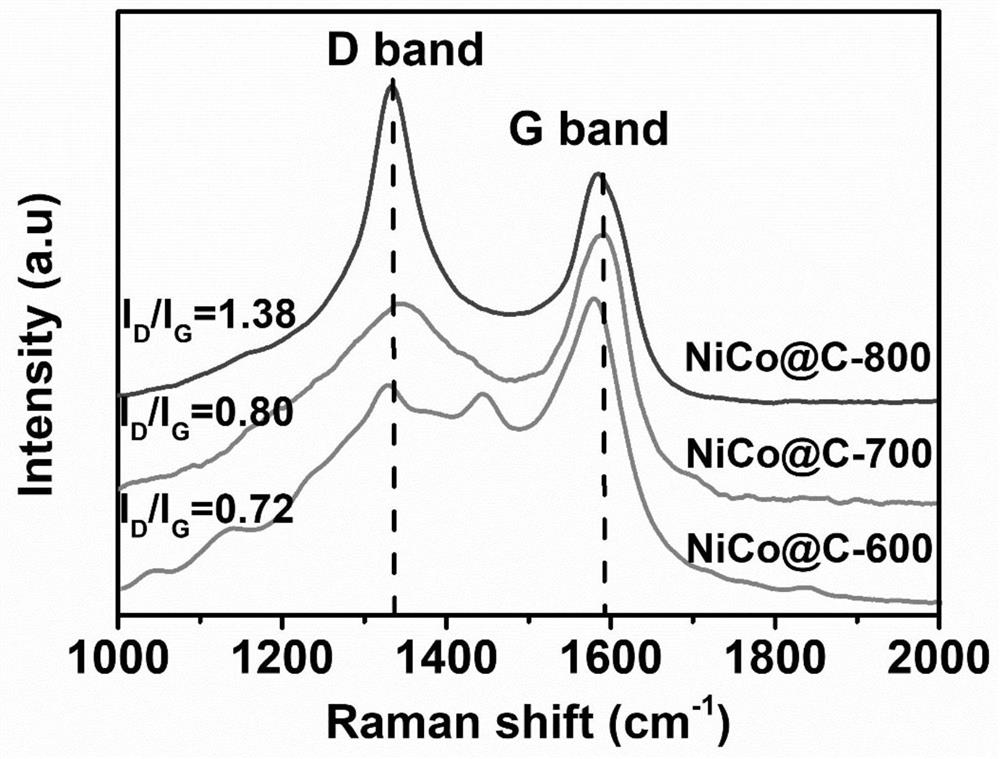

Embodiment 1

[0030] A preparation method of a wave-absorbing material derived from NiCo-MOF / biomass cotton, comprising the steps of:

[0031] (1): Soak 800mg of cotton in 270mL containing H 2 o 2 (2mol / L), Na 2 SiO 3 (0.02 mol / L) and NaOH (0.25 mol / L) mixed aqueous solution. Soak at 90°C for 1 hour. The soaked cotton was washed 6 times with hot water at 70 °C and deionized water at room temperature to remove impurities, and the obtained product was purified and dried under vacuum at 60 °C to obtain activated cotton.

[0032] (2): 106mg of 1,2,3-propanetricarboxylic acid was dissolved in 60mL of DMF (2547mL / g), magnetically stirred for 30min to obtain solution A; 349mg of Ni(NO 3 )·6H 2 O and 349mg Co(NO 3 ) 2 ·6H 2 O (mass ratio of 1:1) was added to the mixed solution of ethanol and water to obtain solution B; after the cotton obtained in step (1) was soaked in solution A and left to stand for 24 hours, the resulting mixed solution was added to the In solution B, react in a stain...

Embodiment 2

[0035] A preparation method of a wave-absorbing material derived from NiCo-MOF / biomass cotton, comprising the steps of:

[0036] (1): Soak 800mg of cotton in 270mL containing H 2 o 2 (2mol / L), Na 2 SiO 3 (0.02 mol / L) and NaOH (0.25 mol / L) mixed aqueous solution. Soak at 90°C for 1 hour. The soaked cotton was washed 6 times with hot water at 70 °C and deionized water at room temperature to remove impurities, and the obtained product was purified and dried under vacuum at 60 °C to obtain activated cotton.

[0037] (2): 106mg of 1,2,3-propanetricarboxylic acid was dissolved in 60mL of DMF (2547mL / g), magnetically stirred for 30min to obtain solution A; 349mg of Ni(NO 3 )·6H 2 O and 349mg Co(NO 3 ) 2 ·6H 2 O (mass ratio of 1:1) was added to the mixed solution of ethanol and water to obtain solution B; after the cotton obtained in step (1) was soaked in solution A and left to stand for 24 hours, the resulting mixed solution was added to the In solution B, react in a stain...

Embodiment 3

[0040] A preparation method of a wave-absorbing material derived from NiCo-MOF / biomass cotton, comprising the steps of:

[0041] (1): Soak 800mg of cotton in 270mL containing H 2 o 2 (2mol / L), Na 2 SiO 3 (0.02 mol / L) and NaOH (0.25 mol / L) mixed aqueous solution. Soak at 90°C for 1 hour. The soaked cotton was washed 6 times with hot water at 70 °C and deionized water at room temperature to remove impurities, and the obtained product was purified and dried under vacuum at 60 °C to obtain activated cotton.

[0042] (2): 106mg of 1,2,3-propanetricarboxylic acid was dissolved in 60mL of DMF (2547mL / g), magnetically stirred for 30min to obtain solution A; 349mg of Ni(NO 3 )·6H 2 O and 349mg Co(NO 3 ) 2 ·6H 2 O (mass ratio of 1:1) was added to the mixed solution of ethanol and water to obtain solution B; after the cotton obtained in step (1) was soaked in solution A and left to stand for 24 hours, the resulting mixed solution was added to the In solution B, react in a stain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com