Nutrient substance separation equipment and use method

A technology for nutrient substances and separation equipment, which is applied in the field of food processing, can solve the problems of precipitation stuck shaft and high impurity content in products, avoid melting, meet the needs of different working conditions, and solve the effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

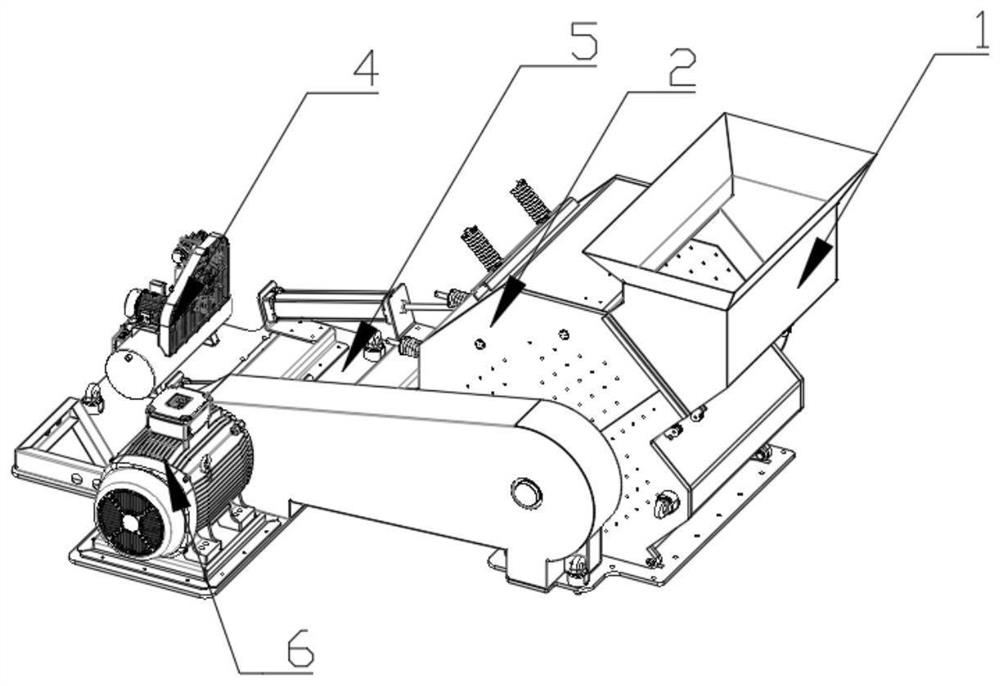

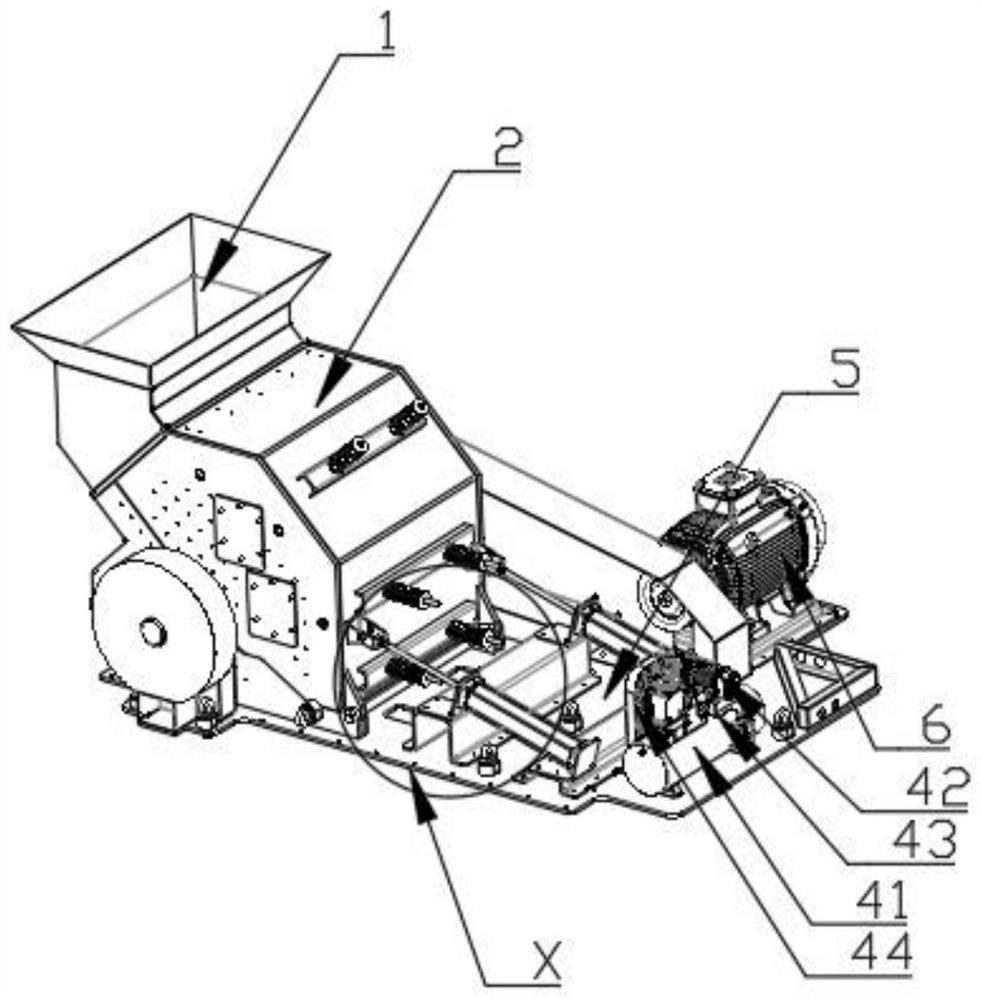

[0063] Such as Figure 1-10 As shown, a nutrient separation device includes a feed separation mechanism 1, a crushing shell 2, a crushing cavity 3, a cooling mechanism 4, and a base 5. The feed separation mechanism 1 is arranged above the crushing shell 2, and the crushing cavity 3 is set Inside the crushing shell 2, the feeding separation mechanism 1 is connected to the crushing cavity 3, the cooling mechanism 4 is installed on the upper part of the base 5, the cooling mechanism 4 is arranged on the left side of the crushing shell 2, and the power mechanism 6 is arranged in front of the crushing shell 2.

[0064] By pouring the nutrient material raw materials into the crushing cavity 3 through the feeding separation mechanism 1, the feeding and separating mechanism 1 screens and separates the passing nutrient material raw materials, and the crushing cavity 3 grinds and pulverizes the nutrient material raw materials. When the temperature is too high, the cooling mechanism 4 co...

Embodiment 2

[0067] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a nutrient separation device includes a feed separation mechanism 1, a crushing shell 2, a crushing cavity 3, a cooling mechanism 4, and a base 5. The feed separation mechanism 1 is arranged above the crushing shell 2, and the crushing cavity 3 is set Inside the crushing shell 2, the feeding separation mechanism 1 is connected to the crushing cavity 3, the cooling mechanism 4 is installed on the upper part of the base 5, the cooling mechanism 4 is arranged on the left side of the crushing shell 2, and the power mechanism 6 is arranged in front of the crushing shell 2.

[0068] By pouring the nutrient material raw materials into the crushing cavity 3 through the feeding separation mechanism 1, the feeding and separating mechanism 1 screens and separates the passing nutrient material raw materials, and the crushing cavity 3 grinds and pulverizes the nutrient material raw mater...

Embodiment 3

[0075] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 A nutrient separation device is shown, which includes a feeding separation mechanism 1, a crushing shell 2, a crushing cavity 3, a cooling mechanism 4 and a base 5. The feeding separation mechanism 1 is set above the crushing shell 2, and the crushing cavity 3 is set on Inside the crushing shell 2, the feeding separation mechanism 1 is connected to the crushing cavity 3, the cooling mechanism 4 is installed on the upper part of the base 5, the cooling mechanism 4 is arranged on the left side of the crushing shell 2, and the power mechanism 6 is arranged in front of the crushing shell 2.

[0076] By pouring the nutrient material raw materials into the crushing cavity 3 through the feeding separation mechanism 1, the feeding and separating mechanism 1 screens and separates the passing nutrient material raw materials, and the crushing cavity 3 grinds and pulverizes the nutrient materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com