Heat dissipation control method and device for vehicle-mounted fuel cell

A technology of fuel cell and control method, which is applied in the direction of fuel cell control, fuel cell heat exchange, fuel cell, etc., and can solve problems such as difficulty in heat dissipation control and incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

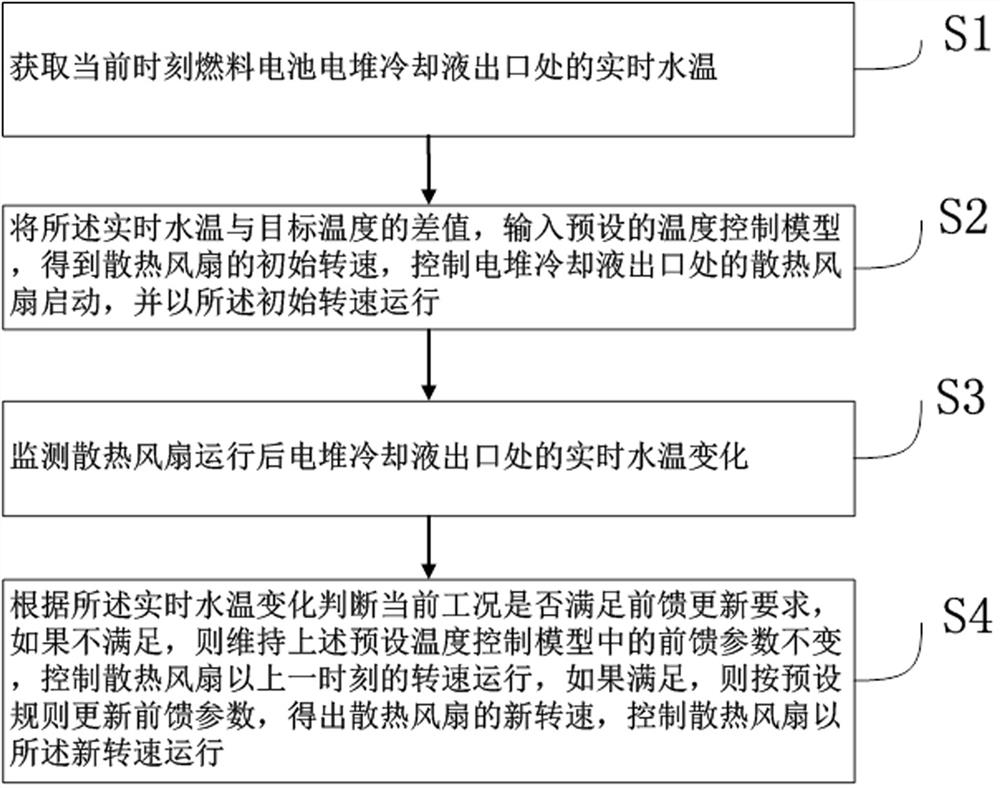

[0065] In one embodiment of the invention, a heat dissipation control method of a vehicle fuel cell is disclosed, and wherein figure 1 As shown, including the following steps:

[0066] S1. Get real-time water temperature at the exit of the current time fuel cell reactor coolant;

[0067] S2. The difference between the high temperature and the target temperature, inputs the preset temperature control model, to obtain the initial speed of the heat dissipation fan, the heat dissipation fan at the outlet of the electric stack coolant is activated, and operates in the initial speed;

[0068] S3. Monitor the real-time water temperature change in the exit of the electric stack coolant after the running hot fan operation;

[0069] S4. Depending on the real-time water temperature change determining whether the current working condition satisfies the feedforward update requirements, if not satisfied, the feedforward parameter in the above preset temperature control model is maintained uncha...

Embodiment 2

[0074] Optimization is performed on the basis of Example 1, and the method further includes step S0 of setting the target temperature, the step S0, which is further refined:

[0075] S01. Get the current time of the ambient temperature, speed, wind speed and altitude;

[0076] S02. Determine the ambient temperature, speed, wind speed, and rated life of the fuel cell to the maximum life of the coolant exit at the highest life;

[0077] S03 acquires the mean of the above water temperature range as a target temperature.

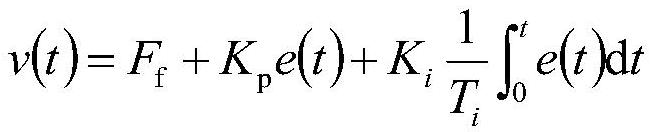

[0078] Preferably, in step S2, the difference of the real-time water temperature and the target temperature is input to the preset temperature control model, and the step of obtaining the initial speed of the heat dissipation fan, further comprising:

[0079] S21. Get the difference E (t) of the real-time water temperature and target temperature at the exit of the current time, the current time.

[0080] S22. Enter the difference E (t) to the preset temperature cont...

Embodiment 3

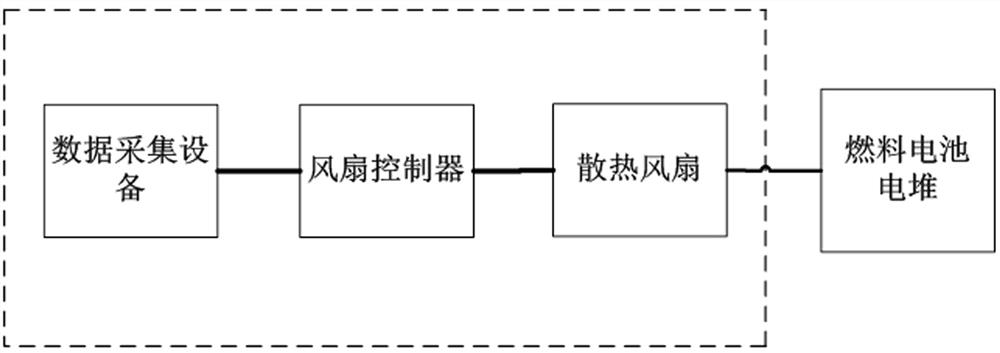

[0109] The present invention also discloses a heat dissipation control device of a vehicle fuel cell corresponding to the method of Examples 1, 2, including data acquisition devices, a fan controller, a cooling fan, such as sequential connection or wireless data transmission. figure 2 Indicated.

[0110] The data acquisition device is used to obtain real-time water temperatures at the exit of the current time fuel cell reactor coolant and send to the fan controller.

[0111] The fan controller is used to obtain the difference between the real-time water temperature and the target temperature of the received, and input the difference to the preset temperature control model to obtain the initial speed of the heat dissipation fan; and control the control of the electric stack coolant The heat dissipation fan at the exit is started and operated in the initial speed; monitoring the real-time water temperature change at the exit of the electric stack coolant after the radiating fan oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com