Automobile air conditioner electric compressor rotational speed control method

An electric compressor and speed control technology, applied in pump control, machine/engine, mechanical equipment, etc., can solve problems such as expensive, difficult to guarantee the effect of new parameters, unfriendly suppliers, etc., to achieve fast system stability, The effect of reducing the calibration workload and reducing the proportional integral coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

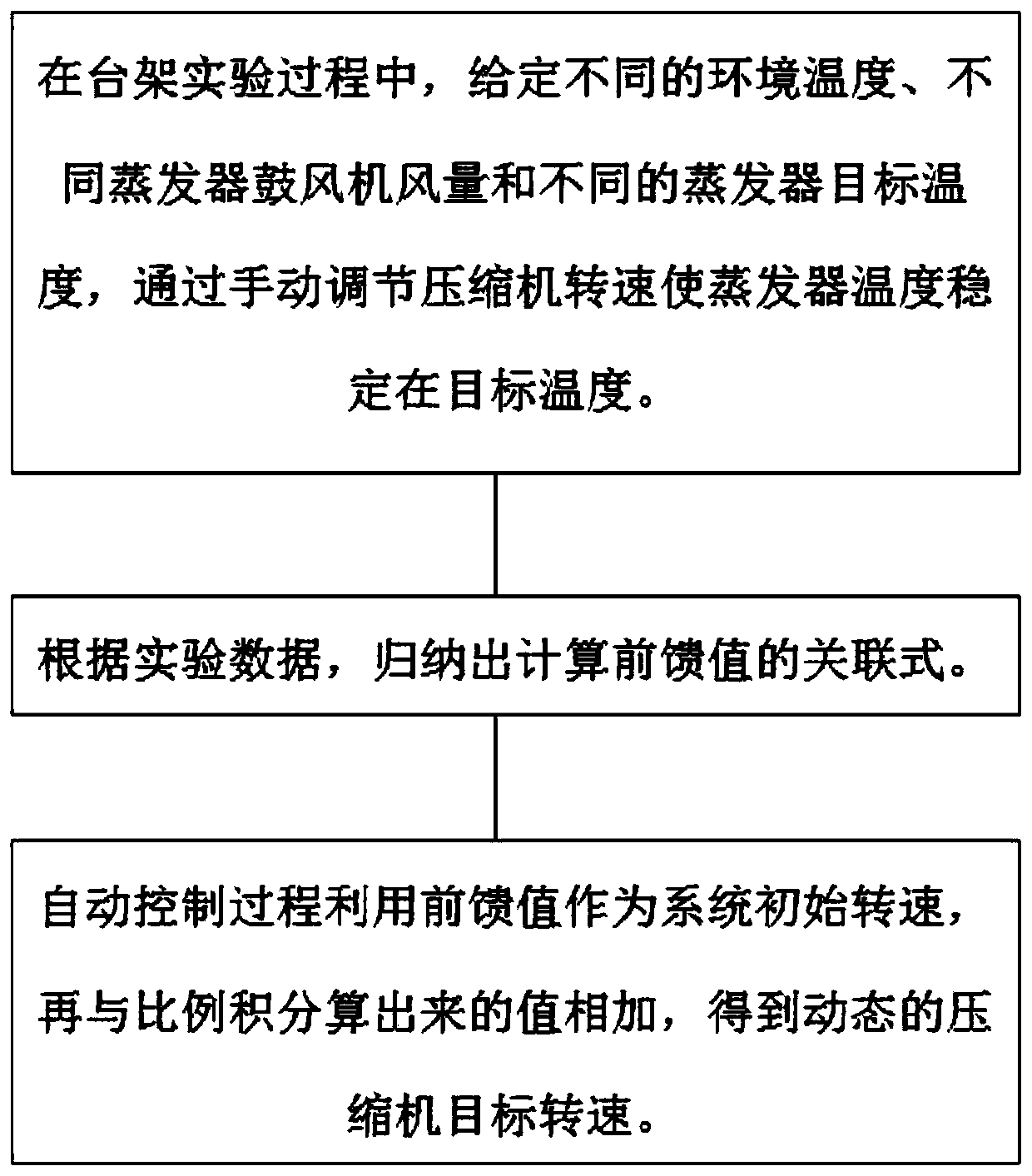

Method used

Image

Examples

Embodiment

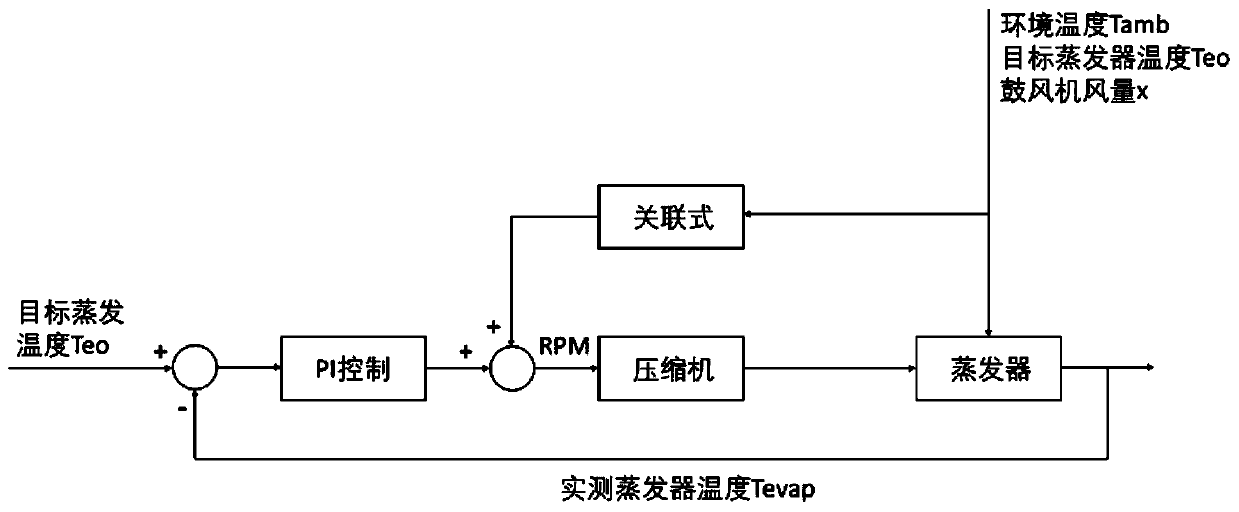

[0027] Example Figure 1 to Figure 3 As shown, assuming that the air volume of the blower is 350kg / h, the ambient temperature is 30°C, and the target evaporator temperature is 3°C, the calculations of K1 and K2 obtained according to the experimental results are as follows:

[0028] K1=0.79+0.09Teo+0.07Tamb+0.0037Teo 2 -0.037Teo*Tamb+0.017Tamb 2 =15.16,

[0029] K2=-273.5+23.62Teo+14.61Tamb-1.353Teo 2 +0.5139Tep*Tamb-0.5873Tamb 2 =-259.02,

[0030] Then the compressor feed-forward speed n=K1*x+K2=5200.98rpm.

[0031] In the general PI algorithm, the starting speed of the given compressor is a fixed value n=1000rpm. The comparison of the two algorithms is shown in the image 3 As shown, it can be seen that the algorithm system of the present invention is used to stabilize the system faster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com