Method for detecting and analyzing small-size non-metallic inclusions in steel by using scanning electron microscope

A technology of non-metallic inclusions and scanning electron microscopy, which is applied in the fields of material analysis using radiation, material analysis using radiation diffraction, material analysis using wave/particle radiation, etc. It can solve the problems of poor stability and low accuracy of quantitative analysis, etc. Accurate and qualitative, easy to operate, large analysis area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

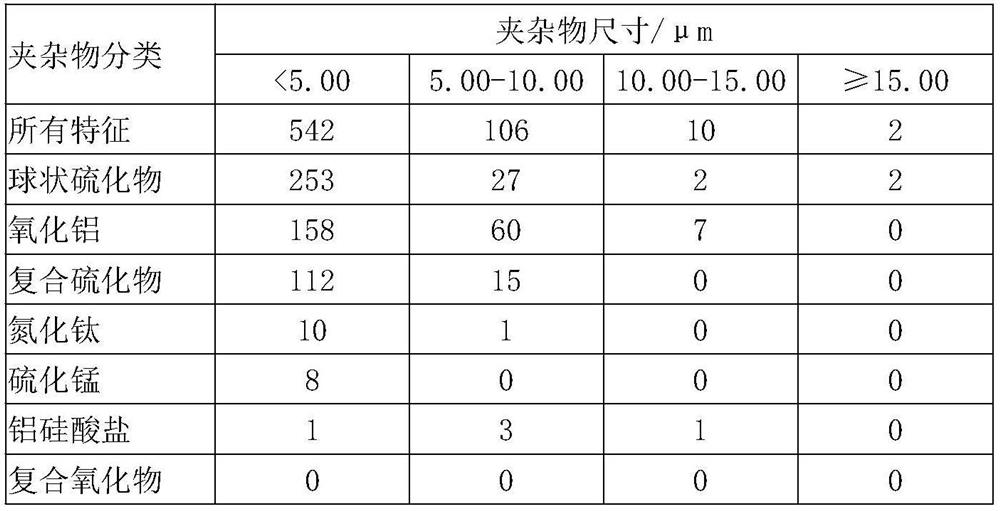

Embodiment 1

[0032] Example 1, detection and analysis of inclusions in a continuous casting slab with a thickness of 200 mm and a designation of B500CL.

[0033] A method for detecting and analyzing small-sized non-metallic inclusions in steel with a scanning electron microscope, comprising the following steps:

[0034] 1) Prepare a metallographic sample, inlay the surface of the sample to be tested with a thermal mosaic machine; polish, polish, and clean the inlaid sample; paste aluminum foil paper on the edge of the sample that is not to be analyzed to obtain a metallographic sample; Specimens are mounted, ground, polished, cleaned, including,

[0035] 1.1) Select the representative position of the continuous casting slab, cut out a sample of 15mm×15mm, and inlay the surface with a hot mosaic machine through the hot mosaic method; grind and polish the mosaic sample, and grind it on the grinding and polishing machine The particle size of sandpaper is selected from 180 mesh to 1200 mesh i...

Embodiment 2

[0048] Example 2, detection and analysis of inclusions in a B550CL hot-rolled plate with a thickness of 2.5 mm.

[0049] A method for detecting and analyzing small-sized non-metallic inclusions in steel with a scanning electron microscope, comprising the following steps:

[0050] 1) Prepare a metallographic sample, inlay the surface of the sample to be tested with a thermal mosaic machine; polish, polish, and clean the inlaid sample; paste aluminum foil paper on the edge of the sample that is not to be analyzed to obtain a metallographic sample; Specimens are mounted, ground, polished, cleaned, including,

[0051] 1.1) Select the representative position of the hot-rolled plate, cut the sample of 20mm×20mm, take four pieces of its longitudinal section 2.5mm×20mm, arrange them together, and use the hot-mounting machine to inlay them by the hot-mounting method; The sample is polished and polished, and the particle size of the sandpaper is selected from 180 mesh to 1200 mesh in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com