Ultrahigh-pressure full-winding gas cylinder with aluminum alloy inner container sealed at one end and manufacturing method of ultrahigh-pressure full-winding gas cylinder

A technology for wrapping gas cylinders and aluminum alloys, applied to ultra-high pressure full-wound gas cylinders with an aluminum alloy liner sealed at one end and its manufacturing field, achieving the effects of simple preparation process, low pollution, and excellent overall strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

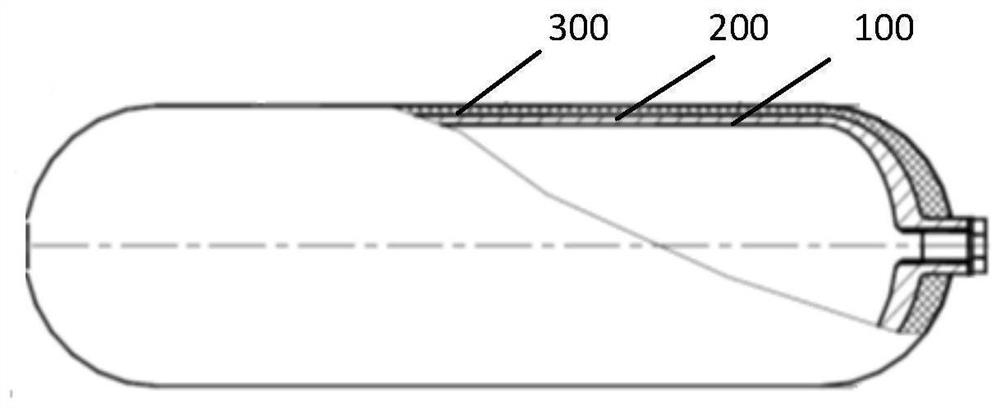

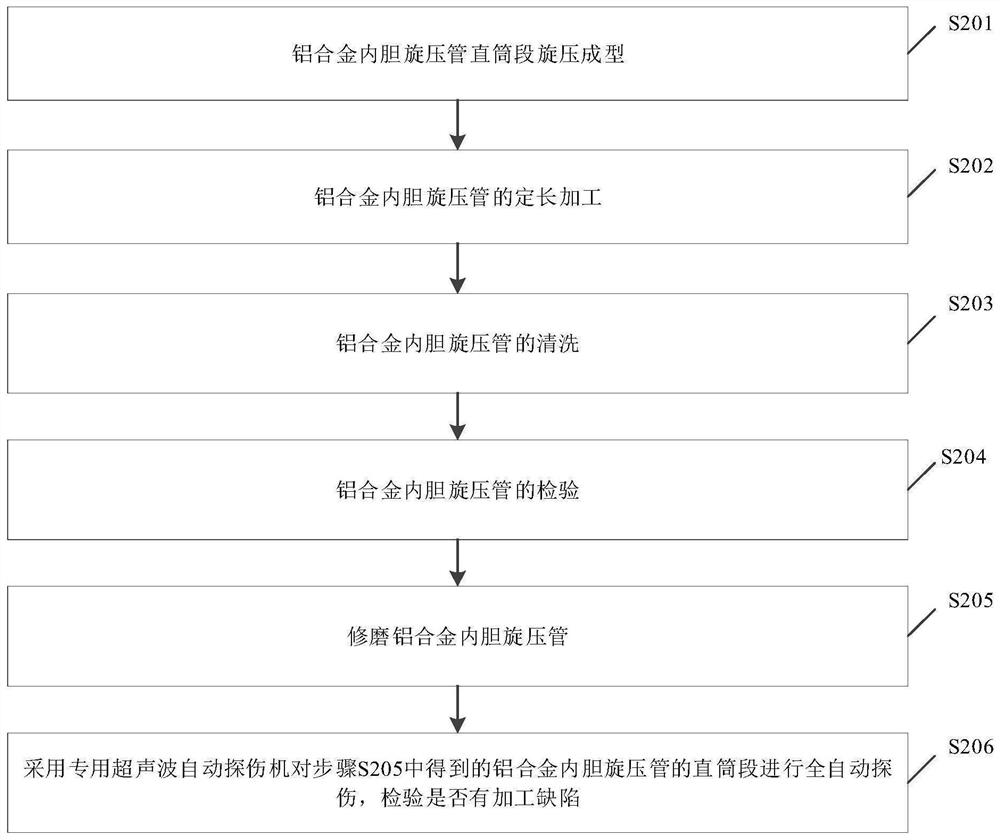

[0183] In the embodiment of the present application, an aluminum alloy liner 100 for a high-pressure gas cylinder with a diameter of 420 mm, a length of 2.5 m, and a wall thickness of 4 mm is manufactured through the above-mentioned method for manufacturing an ultra-high pressure full-winding gas cylinder with an aluminum alloy liner with a one-end back cover. Among them, the rated pressure of the high-pressure gas cylinder is required to be 35Mpa, and the specific steps are as follows:

[0184] Step S1, integral reverse extrusion molding of the blank with the back cover;

[0185] The step S1: using the heating reverse extrusion process combined with the turning and boring process to prepare a seamless pipe consisting of a back cover and a straight section with one end open; specifically, the steps are as follows:

[0186] Aluminum ingot heating, preheating the aluminum ingot to be extruded to 200-400°C;

[0187] Mold heating, preheating both the extrusion outer mold and the ...

Embodiment 2

[0277] In the embodiment of the present application, an aluminum alloy liner 100 for a high-pressure gas cylinder with a diameter of 618mm, a length of 4.5m, and a wall thickness of 6mm was manufactured by the above-mentioned manufacturing method of an ultra-high pressure full-winding gas cylinder with an aluminum alloy liner with one end and a back cover. The rated pressure of the high-pressure gas cylinder is required to be 45Mpa, and the specific steps are as follows:

[0278] Step S1, integral reverse extrusion molding of the blank with the back cover;

[0279] The step S1: using the heating reverse extrusion process combined with the turning and boring process to prepare a seamless pipe consisting of a back cover and a straight section with one end open; specifically, the steps are as follows:

[0280] Aluminum ingot heating, preheating the aluminum ingot to be extruded to 200-400°C;

[0281]Mold heating, preheating both the extrusion outer mold and the inner extrusion r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com