Novel semi-wrapped full-drainage waterproof subway station and construction method

A technology for subway stations and stations, which is applied to drainage, underground chambers, and earth-moving drilling and mining, etc., can solve problems such as difficulty in rectifying hidden water leakage, reduction of mechanized operation, and interruption of operation, etc., to improve waterproof effect and drainage capacity. The effect of simplifying construction organization and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

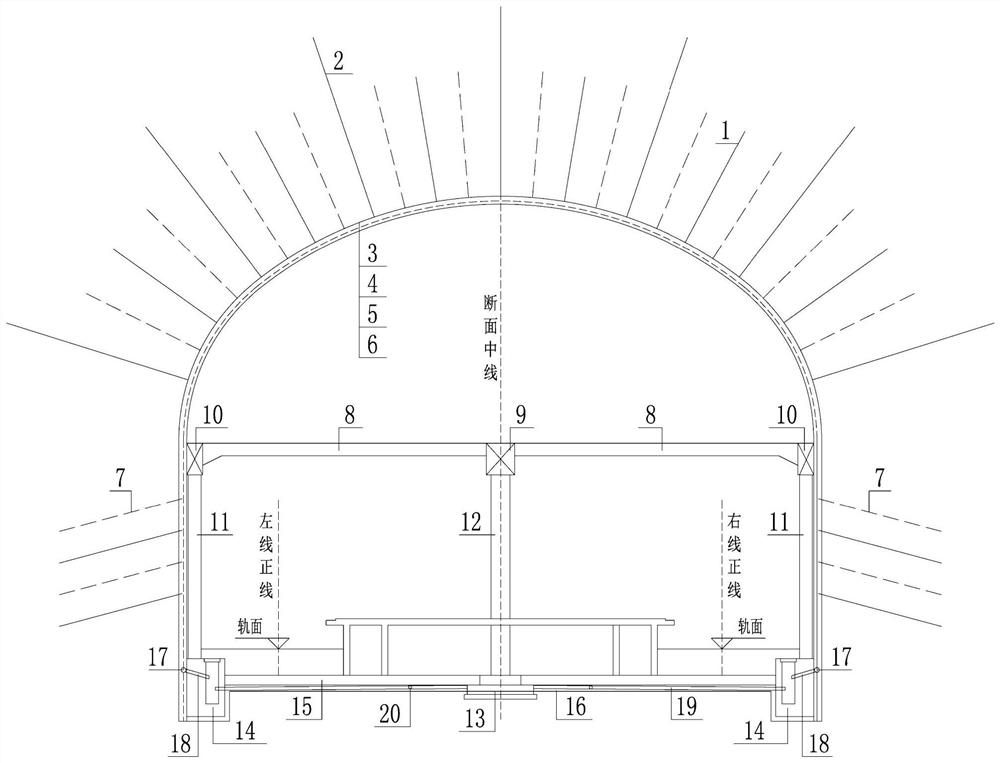

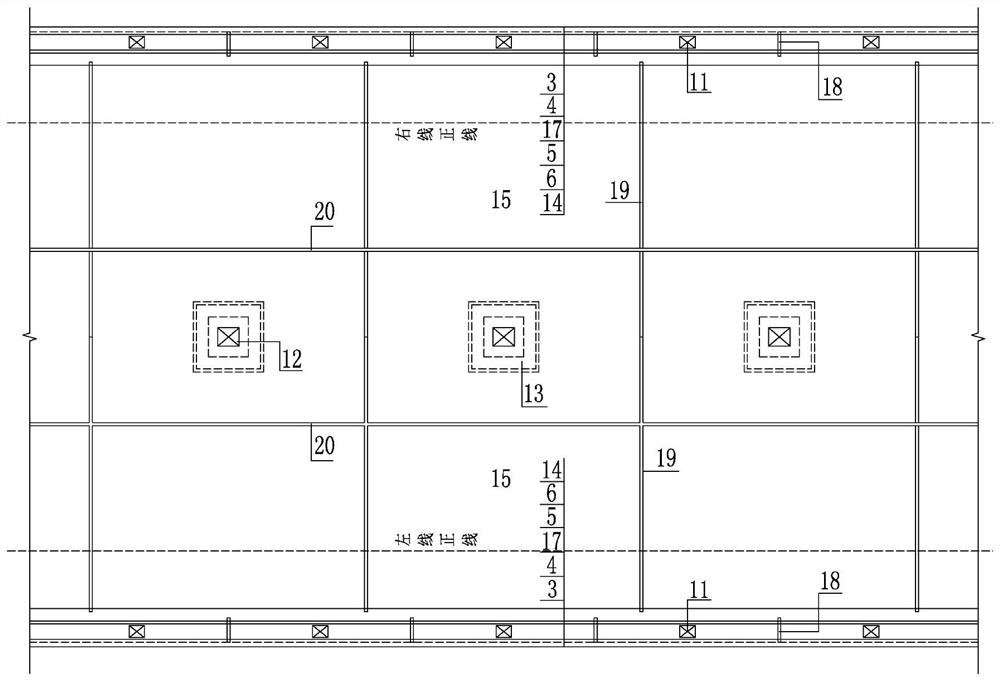

[0032] Embodiment 1: as Figures 1 to 3 As shown, a new type of semi-enclosed and fully drainage and waterproof subway station includes a station arch wall lining, a station floor 15, and drainage gutters 14 arranged on both sides of the station floor; wherein:

[0033] Such as figure 1As shown, the arch wall lining of the station is composed of anchor support layer, capillary drainage plate belt 3, first sprayed concrete layer 4, sprayed waterproof film layer 5 and second sprayed concrete layer 6 arranged in sequence; wherein: The capillary drainage strips 3 are arranged in close contact with the surrounding rock of the tunnel and the first sprayed concrete layer 4 respectively, and the waterproof film layer 5 is sprayed in close contact with the first sprayed concrete layer 4 and the second sprayed concrete layer 6 respectively; A plurality of capillary drainage plate belts 3 are arranged at equal intervals along the length direction of the station, and the ends on both sid...

Embodiment 2

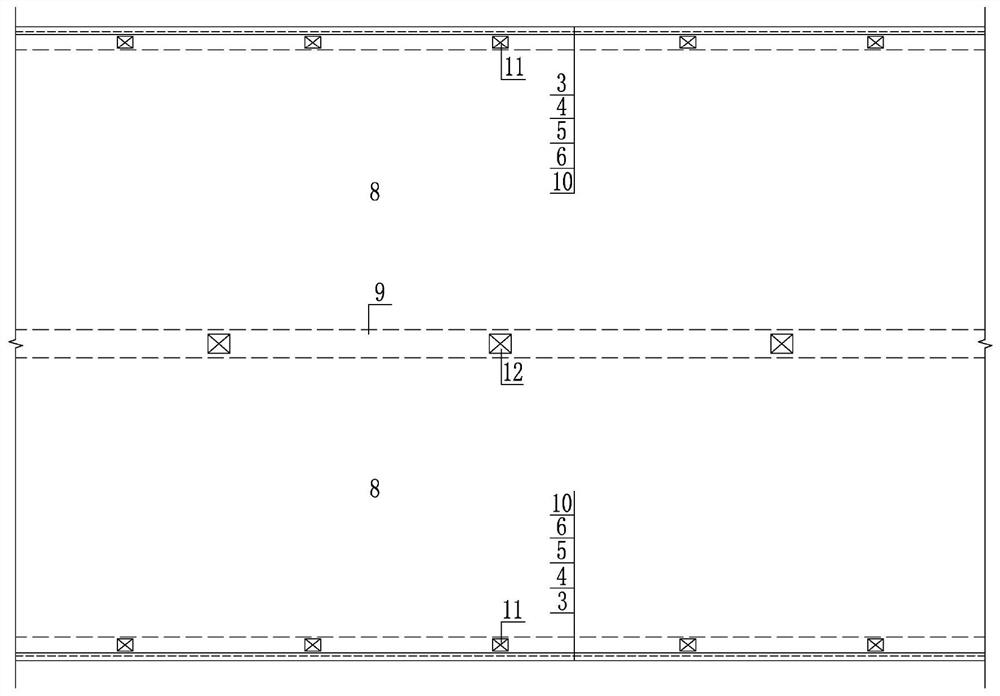

[0037] Embodiment 2: as Figures 1 to 3 As shown, a new semi-enclosed and fully drained waterproof subway station differs from Embodiment 1 in that the main body of the subway station is equipped with a beam, plate, and column bearing system with simple force transmission, and the beam, plate, and column carry The system includes a center plate 8, a center beam 9, two side beams 10, several center columns 12, and several side columns 11, the bottoms of the center columns 12 are respectively provided with independent foundations 13, and the tops of several center columns 12 are connected to the center beam 9; The bottoms of the columns 11 are respectively inserted into the drainage gutters 14 on the side wall of the station, and the tops are respectively connected to the side beams 10; The central column 12 and several side columns 11 jointly support the middle plate 8, the upper part of the middle plate 8 is the station hall floor of the subway station, and the lower part of t...

Embodiment 3

[0042] Embodiment 3: as Figures 1 to 3 Shown, a kind of construction method of construction embodiment 2 described semi-enclosed full drainage and waterproof novel subway station, comprises following construction steps:

[0043] S1, Excavate each part of the rock mass in blocks and layers according to the design method, and apply the corresponding bolt support for the arch and side walls in sequence;

[0044] S2, after the excavation of each cycle of rock mass and bolt support is completed, the capillary drainage strip 3 is immediately laid close to the surrounding rock, and the first sprayed concrete layer 4 is applied in time to seal the surrounding rock, forming an early pressure bearing structure of the surrounding rock , and at the same time, pre-buried the vertical drainage blind pipe 17 and the horizontal drain pipe 18 at a suitable elevation position at the bottom of the side wall, and the horizontal drain pipe 18 should be protected by reliable measures to prevent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com