Cobalt oxide for coating positive electrode material of lithium battery and preparation method thereof

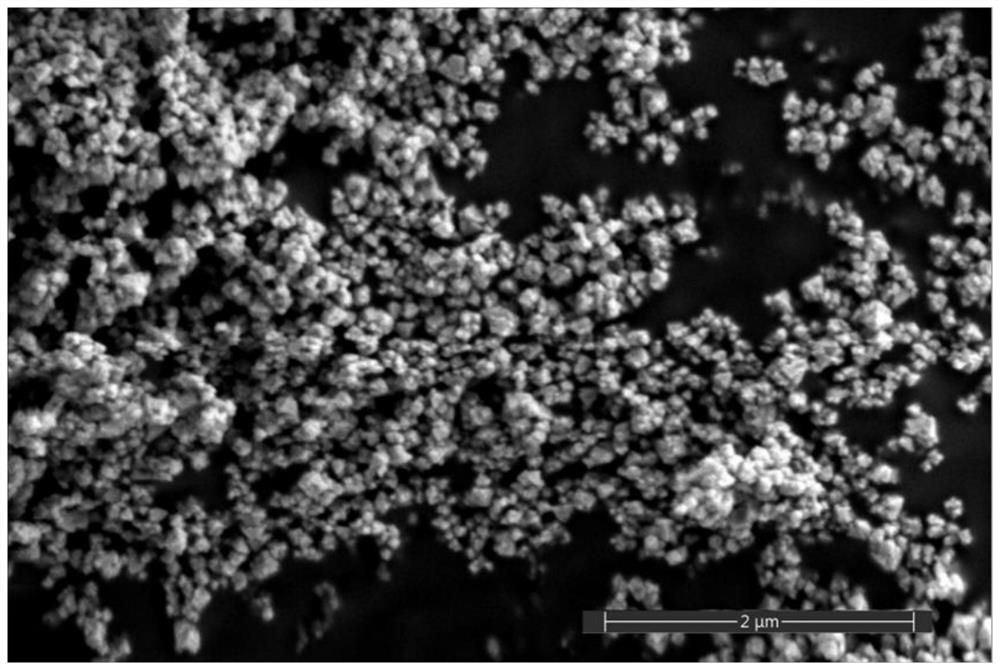

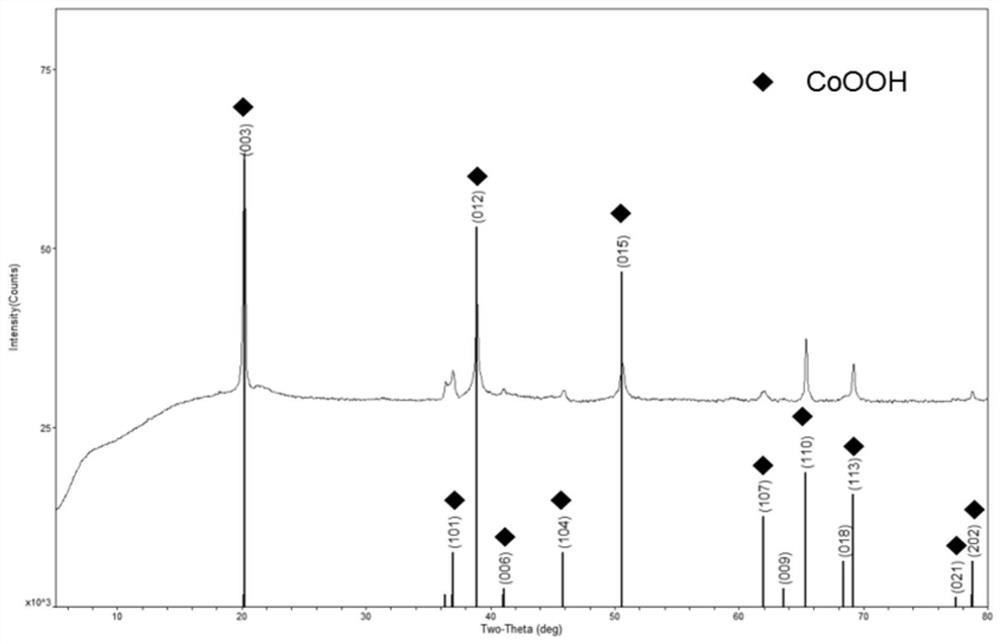

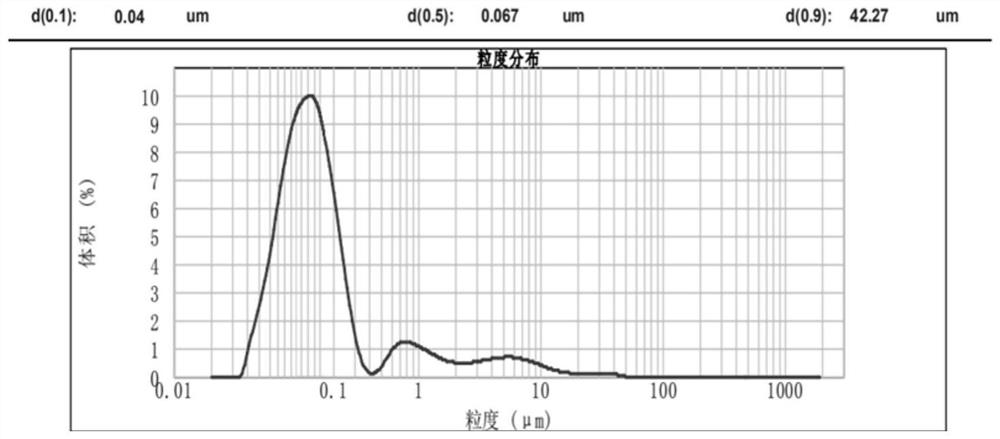

A cobalt oxide and coating technology, which is applied to the field of cobalt oxide for coating cathode materials of lithium batteries and its preparation, can solve the problems of large specific surface area, poor dispersibility and high particle surface energy, and achieves large specific surface area and small particle size. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention also provides a method for preparing cobalt oxide with a large specific surface area, the method comprising the following steps:

[0040](1) preparation of cobalt ion concentration is the non-complexed cobalt salt solution of 60~150g / L, and configuration concentration is the sodium hydroxide solution of 80~440g / L;

[0041] (2) Under stirring conditions, cobalt salt solution and sodium hydroxide solution are added into the reaction kettle concurrently, and the pH value is controlled at 8 to 12 to generate cobaltous hydroxide. The reaction time is 60 to 120 minutes. Into nitrogen as a protective gas to prevent the cobaltous hydroxide generated from being oxidized;

[0042] (3) stop feeding, stop feeding nitrogen, start to feed the air as the first oxidant, and add the second oxidizer that oxidizing power is stronger than the first oxidant in the reactor, to oxidize cobaltous hydroxide, wherein Control the molar ratio of the second oxidant to the cob...

Embodiment 1

[0055] Solution preparation: mix cobalt sulfate with pure water to prepare a cobalt sulfate solution with a cobalt ion concentration of 60g / L; mix sodium hydroxide with pure water to prepare a sodium hydroxide solution with a concentration of 80g / L.

[0056] Synthesis of cobaltous hydroxide: add pure water to the reaction kettle as the bottom liquid, and pump the prepared cobalt sulfate solution and sodium hydroxide solution into the reaction kettle at the same time at a temperature of 30°C and a stirrer speed of 130rpm to control the reaction The pH is between 8 and 8.3, the reaction time is 60 minutes, and nitrogen gas is introduced as a protective gas, and the flow rate of nitrogen gas is 0.3m 3 / h.

[0057] Oxidation treatment: After the reaction of synthesizing cobaltous hydroxide is completed, stop feeding nitrogen and start feeding air, and the air flow rate is controlled to 0.2m 2 / h, while the oxidizing agent hypochlorous acid is added in the reactor, the molar ratio...

Embodiment 2

[0062] Prepare solution: mix cobalt chloride with pure water to prepare a cobalt chloride solution with a cobalt ion concentration of 100g / L; mix sodium hydroxide with pure water to prepare a sodium hydroxide solution with a concentration of 250g / L.

[0063] Synthesis of cobaltous hydroxide: add pure water to the reaction kettle as the bottom liquid, and pump the prepared cobalt salt cobalt chloride solution and sodium hydroxide solution into the reaction kettle at the same time at a temperature of 50°C and a stirrer speed of 130rpm , control the reaction pH at 9.5 ~ 10.0, the reaction time is 90min, and nitrogen gas is introduced as a protective gas, and the nitrogen flow rate is 1.5m 3 / h.

[0064] Oxidation treatment: After the reaction of synthesizing cobaltous hydroxide is completed, stop feeding nitrogen and start feeding air, and the air flow rate is controlled to 0.55m 2 / h, while adding the oxidizing agent sodium persulfate into the reaction kettle, controlling the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com