Catalyst component for olefin polymerization, preparation method and application thereof

A technology of olefin polymerization and olefin polymer, applied in the field of polyolefin catalysts, can solve the problems of easy adhesion of catalyst particles, difficulty in controlling reaction conditions, and long prepolymerization time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

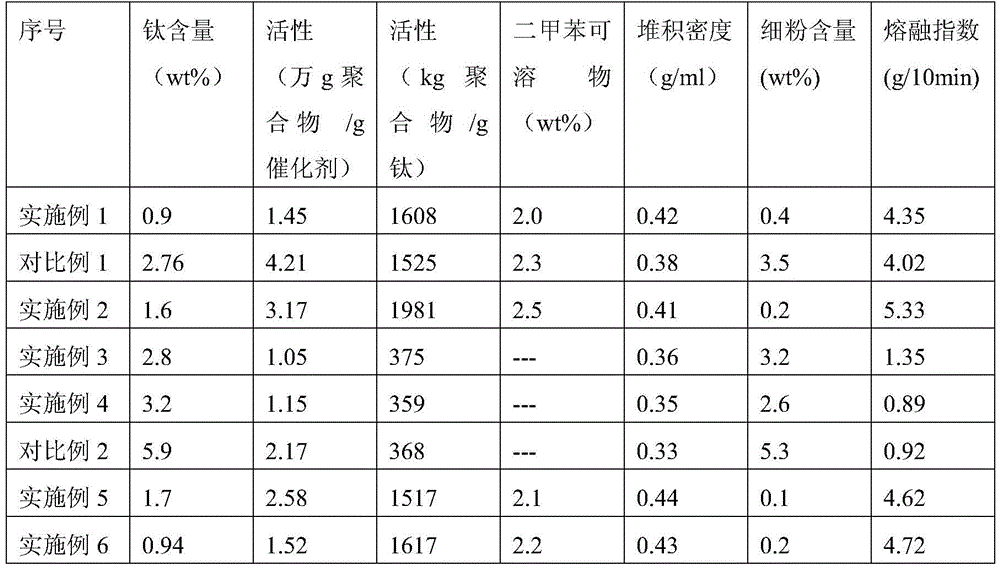

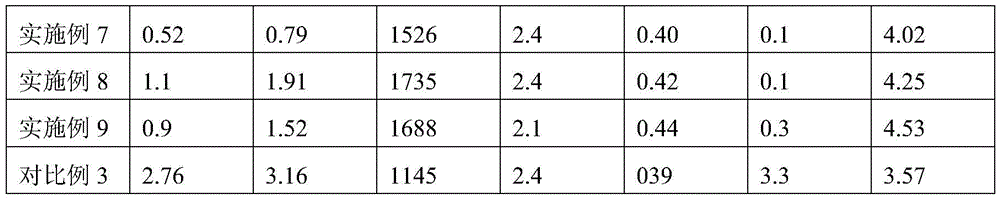

Examples

Embodiment 1

[0100] 1. Preparation of catalyst components:

[0101] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, then maintain 0°C and add 20mL of titanium tetrachloride dropwise, and then slowly raise the temperature to 80°C , add 3.6mL DNBP (dibutyl phthalate), then continue to heat up to 110 ° C for 2 hours, then press filter the liquid, filter off the liquid, and wash the obtained solid three times with 100 mL toluene at 90 ° C. Then, a mixed solution of 20 ml of titanium tetrachloride and 80 ml of toluene was added and stirred at 110° C. for 1 hour, and the liquid was filtered off. The obtained solid was washed 5 times with 100 mL of hexane at 60° C., and the liquid was filtered off. Add 300mL of n-hexane into the flask, add 4ml of 0.5mol / L triethylaluminum hexane solution, control the temperature at 5°C, and keep the temperature constant for 5 minutes; feed ethylene gas through a mass flow meter...

Embodiment 2

[0110] 1. Preparation of catalyst components:

[0111] In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, then maintain 0°C and dropwise add 80mL of titanium tetrachloride, and slowly heat up to 80°C, add 3.6mL DIBP (diisobutyl phthalate), then continue to heat up to 120°C for 2 hours at a constant temperature, then press filter the liquid, filter off the liquid, and use 120mL titanium tetrachloride to dissolve the obtained solid at 125°C Wash 3 times. The obtained solid was washed twice with 150 mL of hexane at 60°C and twice at room temperature. Add 300mL of n-hexane into the flask, add 8ml of 0.5mol / L triisobutylaluminum hexane solution, control the temperature at 18°C, and keep the temperature constant for 20 minutes; feed propylene gas through a mass flow meter, and control the feeding speed of propylene 20g / h, react for 60 minutes. The air intake was stopped, and nitrogen replacement wa...

Embodiment 3

[0115] 1. Preparation of catalyst components:

[0116]In a 500ml stirred 5-neck flask fully replaced by nitrogen, add 10g of diethoxymagnesium and 80mL of toluene to prepare a suspension, then maintain 0°C and add 20mL of titanium tetrachloride dropwise, and then slowly raise the temperature to 110°C The temperature was kept constant for 2 hours, and then the liquid was press-filtered to remove the liquid, and the obtained solid was washed three times with 100 mL of toluene at 90°C. Then, a mixed solution of 20 ml of titanium tetrachloride and 80 ml of toluene was added and stirred at 110° C. for 1 hour, and the liquid was filtered off. The obtained solid was washed 5 times with 100 mL of hexane at 60° C., and the liquid was filtered off. Add 300mL of n-hexane into the flask, add 4ml of 0.5mol / L tri-n-hexylaluminum hexane solution, control the temperature at 5°C, and keep the temperature constant for 5 minutes; feed ethylene gas through a mass flow meter, and control the feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com